Method for preparing fibrous zirconium dioxide aerogel

A zirconia, aerogel technology, applied in zirconia, chemical instruments and methods, colloidal chemistry, etc., can solve problems such as single morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

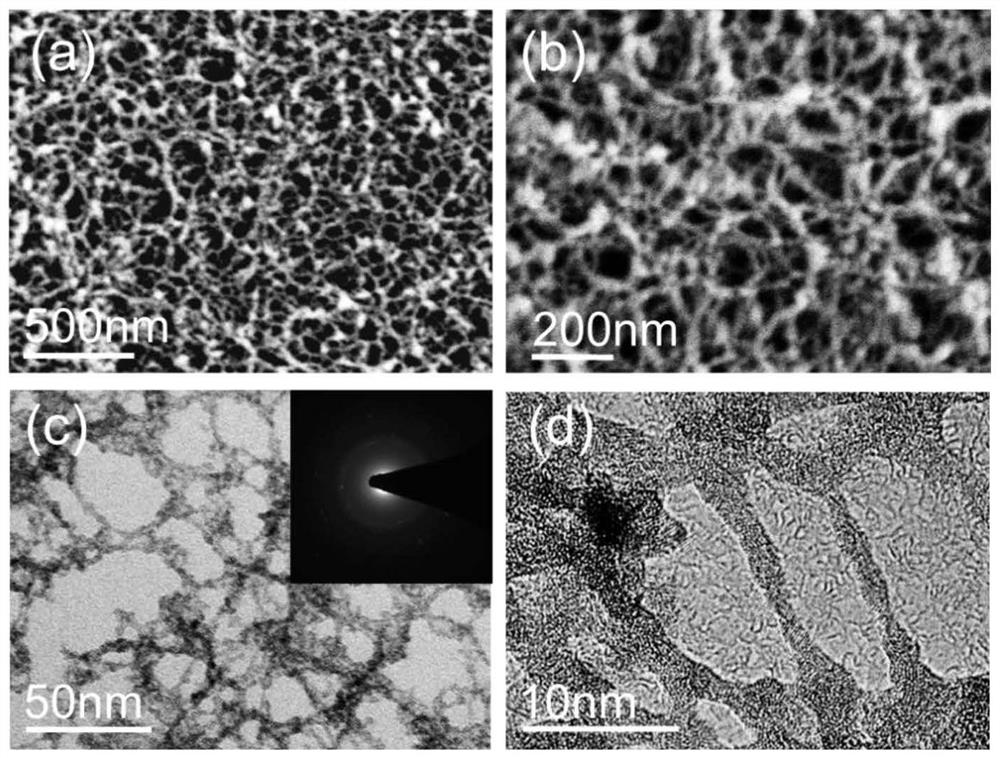

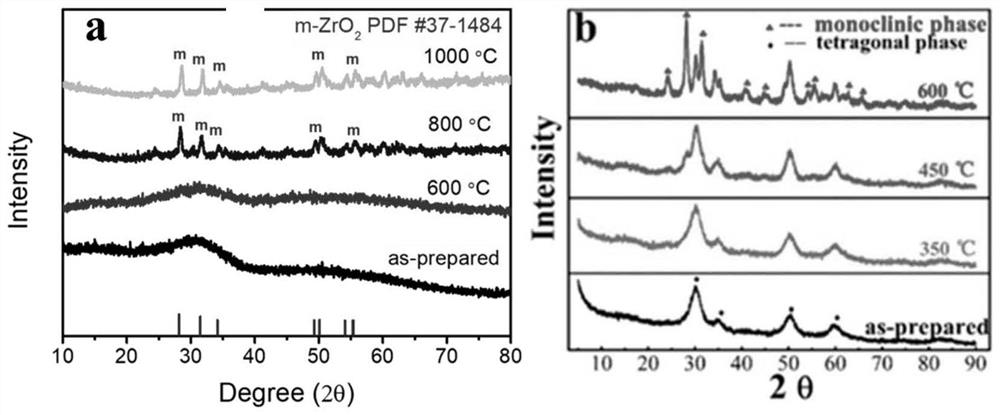

[0026] Example 1: Fibrous zirconia aerogel was prepared as follows:

[0027] 1) Configure zirconium salt precursor solution: 1.93g ZrOCl 2 ·8H 2 O was added to 60 mL of absolute ethanol, where [Zr 4 + ]=0.1mol / L, sealed with plastic wrap, and stirred on a magnetic stirrer until completely dissolved.

[0028] 2) Add 6 mL of 30% hydrogen peroxide solution (with a volume ratio of 1 / 10 to the zirconium salt precursor solution) into the above solution, and stir to obtain a mixed solution;

[0029]3) Configure gel accelerator solution: add 0.09 g of mercaptosuccinic acid to 6 mL of ethanol, stir until dissolved, and the concentration of mercaptosuccinic acid in the solution is 0.1 mol / L. All the mercaptosuccinic acid ethanol solution was added to the mixed solution, stirred rapidly, sealed and placed in a 25°C oven for 2 hours to obtain a wet gel;

[0030] 4) Put the wet gel into a glass dish filled with absolute ethanol, seal it, and put it into an oven at 40° C. for 5 days of...

Embodiment 2

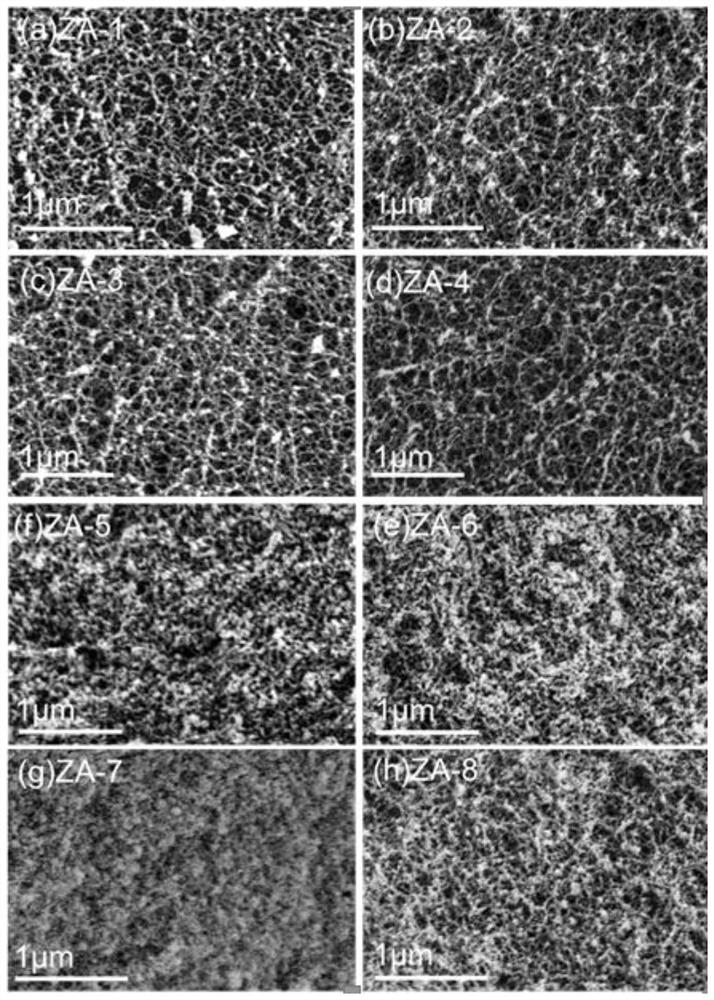

[0035] 1) Configure zirconium salt precursor solution: 57.9g ZrOCl 2 ·8H 2 O was added to 60 mL of absolute ethanol, where [Zr 4 + ]=3mol / L, sealed with plastic wrap, and stirred on a magnetic stirrer until completely dissolved.

[0036] 2) Add 60 mL of 0.1% hydrogen peroxide solution (with a volume ratio of 1 / 1 to the zirconium salt precursor solution) into the above solution, and stir to obtain a mixed solution;

[0037] 3) Configure gel accelerator solution: add 9 g of mercaptosuccinic acid into 30 mL of ethanol, stir until dissolved, and the concentration of mercaptosuccinic acid in the solution is 10 mol / L. All the ethanol solution of mercaptosuccinic acid was added to the mixed solution, stirred rapidly, sealed and placed in an oven at 45°C for 12 hours to obtain a wet gel;

[0038] 4) Put the wet gel into a glass dish filled with absolute ethanol, seal it, and put it into an oven at 70° C. for aging for 2 d.

[0039] 5) the wet gel obtained after aging is put into ...

Embodiment 3

[0042] 1) Configure zirconium salt precursor solution: 19.3g ZrOCl 2 ·8H 2 O was added to 60 mL of absolute ethanol, where [Zr 4 + ]=1mol / L, seal with plastic wrap, stir on a magnetic stirrer until completely dissolved.

[0043] 2) Add 18 mL of 10% hydrogen peroxide solution (with a volume ratio of 1 / 3 to the zirconium salt precursor solution) into the above solution, and stir to obtain a mixed solution;

[0044] 3) Configure the gel accelerator solution: add 2.7 g of mercaptosuccinic acid to 18 mL of ethanol (with a volume ratio of 1 / 3 to the zirconium salt precursor solution), stir until dissolved, and the concentration of mercaptosuccinic acid in the solution is 1 mol / L. All the ethanol solution of mercaptosuccinic acid was added to the mixed solution, stirred rapidly, sealed and placed in a 70°C oven for 1 hour to obtain a wet gel;

[0045] 4) Put the wet gel into a glass dish filled with absolute ethanol, seal it, and put it into an oven at 25° C. for aging for 7 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com