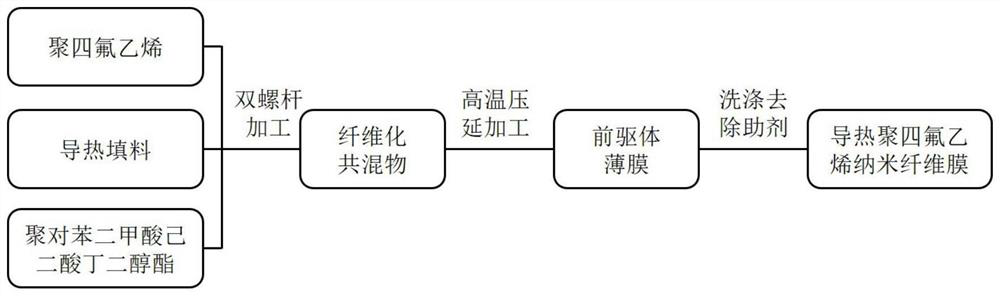

High-thermal-conductivity polytetrafluoroethylene nanofiber membrane and manufacturing process thereof

A technology of polytetrafluoroethylene and nanofiber membranes, which is applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as high thermal conductivity and difficulty in production, and achieve high wear resistance and high durability Thermal, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

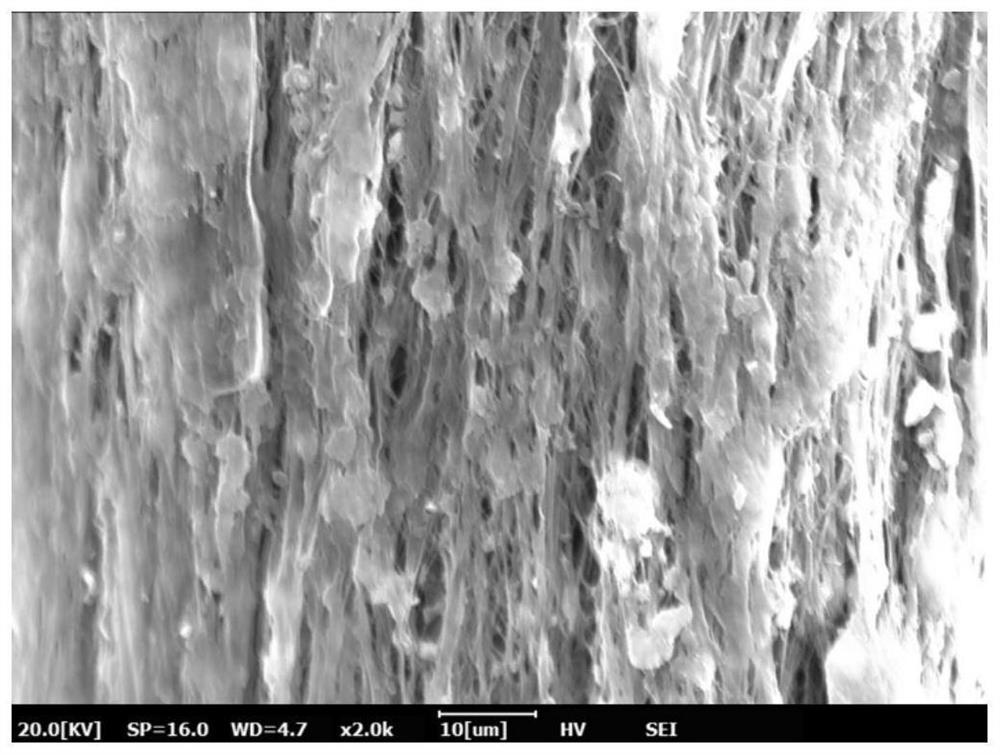

[0050] Taking nano-hexagonal boron nitride (nBN) as the thermal conductive filler, the preparation of high thermal conductivity PTFE nanofiber film is an example. The raw material is polybutylene terephthalate adipate produced by Lanshan Tunhe Company, Shanghai It is nano-hexagonal boron nitride powder produced by Ou Nano Technology Co., Ltd., and acrylic modified PTFE produced by Mitsubishi Chemical Co., Ltd. The blending equipment used in the experiment was a twin-screw extruder manufactured by Rice Company, the etching solvent was dimethylformamide, and the annealing equipment was a high-temperature tube furnace.

[0051] In the first step, the mixed powder raw materials consisting of 20% polytetrafluoroethylene powder, 20% nano-hexagonal boron nitride, and 60% polybutylene terephthalate adipate particles are placed in the Physical dry mixing is carried out in a rotating mixing tank.

[0052] In the second step, the dry-mixed powder is put into the feed port of the twin-sc...

Embodiment 2

[0058] Taking graphene and carbon nanotubes as thermal conductive fillers and powdered polytetrafluoroethylene as raw materials, the preparation of high thermal conductive polytetrafluoroethylene nanofiber membranes is an example. The raw materials are polyethylene terephthalate produced by Lanshan Tunhe Company. Butylene glycol ester, graphene and carbon nanotubes produced by Chengdu Organic, and acrylic modified polytetrafluoroethylene produced by Mitsubishi Chemical. The blending equipment used in the experiment was a twin-screw extruder manufactured by Rice Company, the etching solvent was dichloromethane, and the annealing equipment was a high-temperature tube furnace.

[0059] In the first step, the polybutylene terephthalate adipate particles are dissolved in dichloromethane, 100ml of dichloromethane contains 10g polybutylene terephthalate adipate, 2g graphene, and 2g carbon Nanotubes, using sodium dodecyl sulfate as a dispersant, ultrasonically dispersing the solution ...

Embodiment 3

[0066] Taking nano silver fiber as thermal conductive filler and powdered PTFE as raw material, the preparation of high thermal conductive PTFE nanofiber film is taken as an example. The raw material is polybutylene terephthalate adipate produced by Lanshan Tunhe Company. Alcohol esters, laboratory-made nano-silver fibers, and acrylic-modified polytetrafluoroethylene produced by Mitsubishi Chemical Corporation. The blending equipment used in the experiment was a twin-screw extruder manufactured by Rice Company, the etching solvent was dichloromethane, and the annealing equipment was a high-temperature tube furnace.

[0067] In the first step, the polybutylene terephthalate adipate particles are dissolved in dichloromethane, 200ml of dichloromethane contains 15g polybutylene terephthalate adipate, 7.5g nano-silver fibers, using Sodium dodecyl sulfate was used as a dispersant. After ultrasonically dispersing the solution for 5 hours, the solution was placed in a vacuum drying ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com