Anti-pollution separation net as well as preparation method and application thereof

An anti-pollution and net-separation technology is applied in chemical instruments and methods, textiles and papermaking, general water supply conservation, etc. It can solve problems such as unfavorable, reduced antibacterial performance of the net, weakened bacterial activity, etc., and achieves strong self-cleaning ability, Effect of low feed side pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

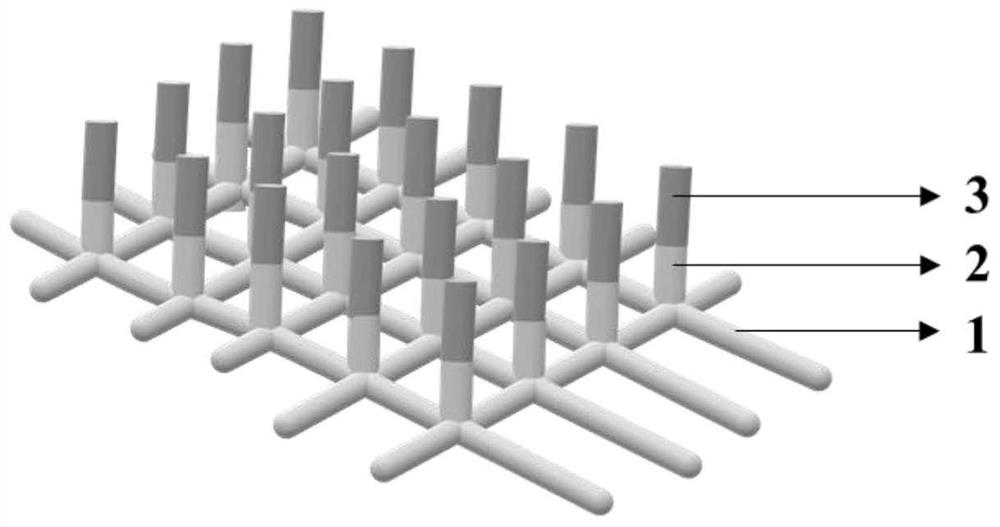

[0103] This embodiment provides an anti-pollution screen, the schematic diagram of which is as follows: figure 1 As shown, the anti-pollution separator includes a polypropylene separator 1, and an anti-pollution polymer brush disposed on the surface of the separator;

[0104] The anti-pollution polymer brush includes a poly-N-isopropylacrylamide temperature-sensitive polymer brush 2, and a poly-2-(perfluoropolymer) grafted on the end of the poly-N-isopropylacrylamide temperature-sensitive polymer brush. Octyl) ethyl methacrylate polymer brush 3;

[0105] The poly-N-isopropylacrylamide thermosensitive polymer brush is in direct contact with the separator.

[0106] The anti-pollution screen is prepared by the following method, and the method includes the following steps:

[0107] (1) dissolve 7g of ammonium persulfate in 30mL of deionized water, and configure to obtain 18.9% ammonium persulfate solution;

[0108] Place 0.2 g of polypropylene separator (taken from a new roll-t...

Embodiment 2

[0122]This embodiment provides an anti-pollution screen, which is different from Embodiment 1 in that the poly-N-isopropylacrylamide temperature-sensitive polymer brush is a polydimethylaminoethyl methacrylate brush; the preparation method thereof is the same as The difference of Example 1 is that the N-isopropylacrylamide in step (3) is replaced with an equimolar amount of dimethylaminoethyl methacrylate.

Embodiment 3

[0124] This embodiment provides an anti-pollution screen, which is different from Embodiment 1 in that the poly-N-isopropylacrylamide temperature-sensitive polymer brush is a polyethylene glycol monomethyl ether methacrylate brush; its preparation The difference between the method and Example 1 is that the N-isopropylacrylamide in step (3) is replaced with an equimolar amount of ethylene glycol monomethyl ether methacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com