Piezoelectric resonator and its parts

A piezoelectric resonator and piezoelectric technology, applied in the direction of electrical components, impedance networks, etc., can solve problems such as inability to produce stable oscillations, uneven connection areas, and unstable bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

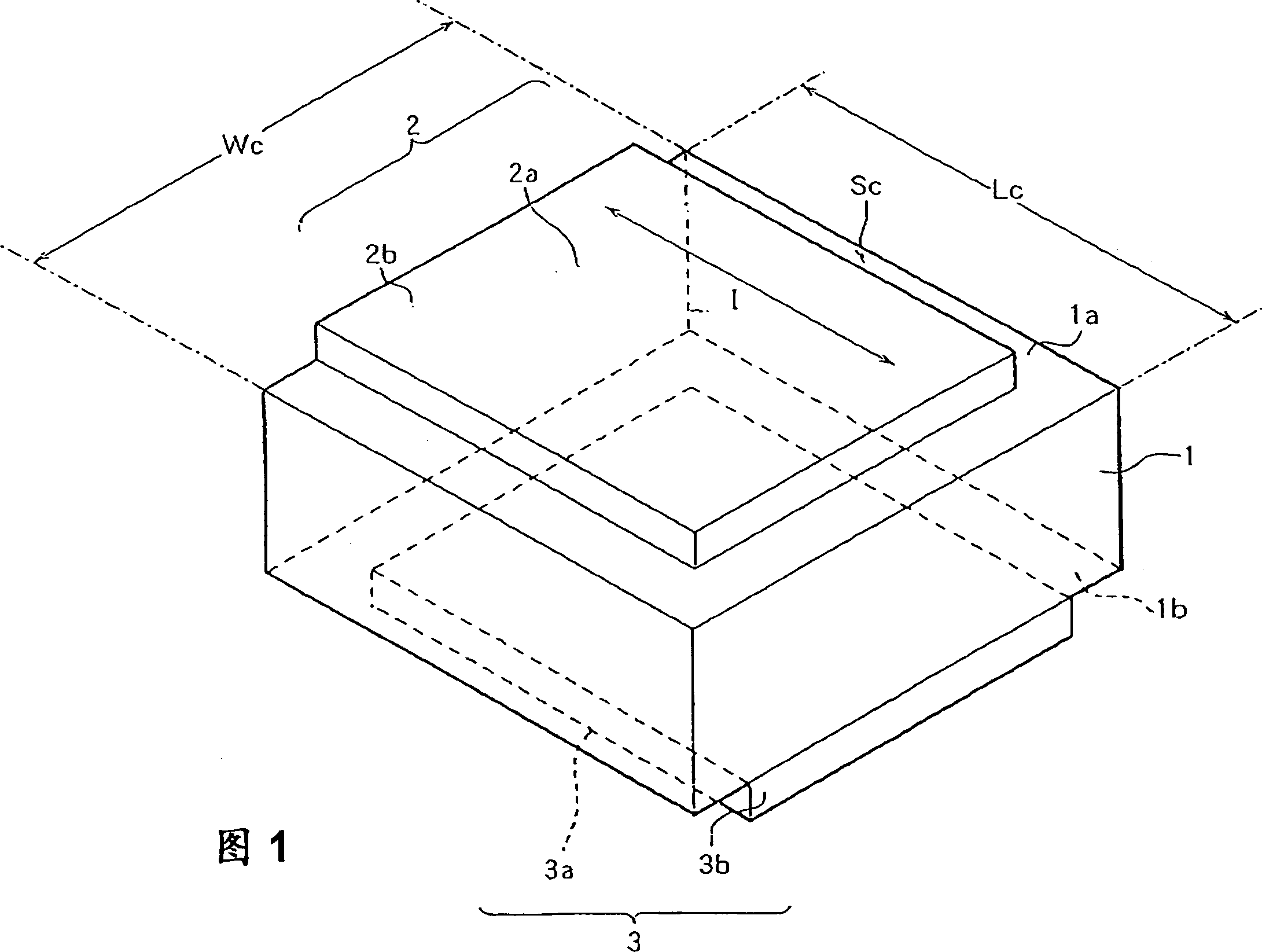

[0068] Fig. 1 shows the structure of a piezoelectric resonator of an embodiment of the present invention. The piezoelectric resonator is equipped with: a piezoelectric substrate 1 with a pair of opposite surfaces 1a and 1b and an effective Poisson's ratio smaller than 1 / 3; Corresponding to the opposite surfaces 1a, 1b.

[0069] The opposite surfaces 1a, 1b of the piezoelectric base layer 1 have almost the same shape, such as a rectangle, respectively. A rectangular shape as referred to herein is a substantially sensed shape. So, slightly off corners or corners that are not exactly 90 degrees are allowed. The sum α of the length of the vertical side of one of the opposite surfaces 1a, 1b and the length of the other side of the opposite surface is limited to a range of 2.22 to 2.24mm or 2.34 to 2.48mm. That is to say, assuming that the length of the one side is Lc and the length of the other side is Wc, the relationship between the length Lc of the one side and the length Wc ...

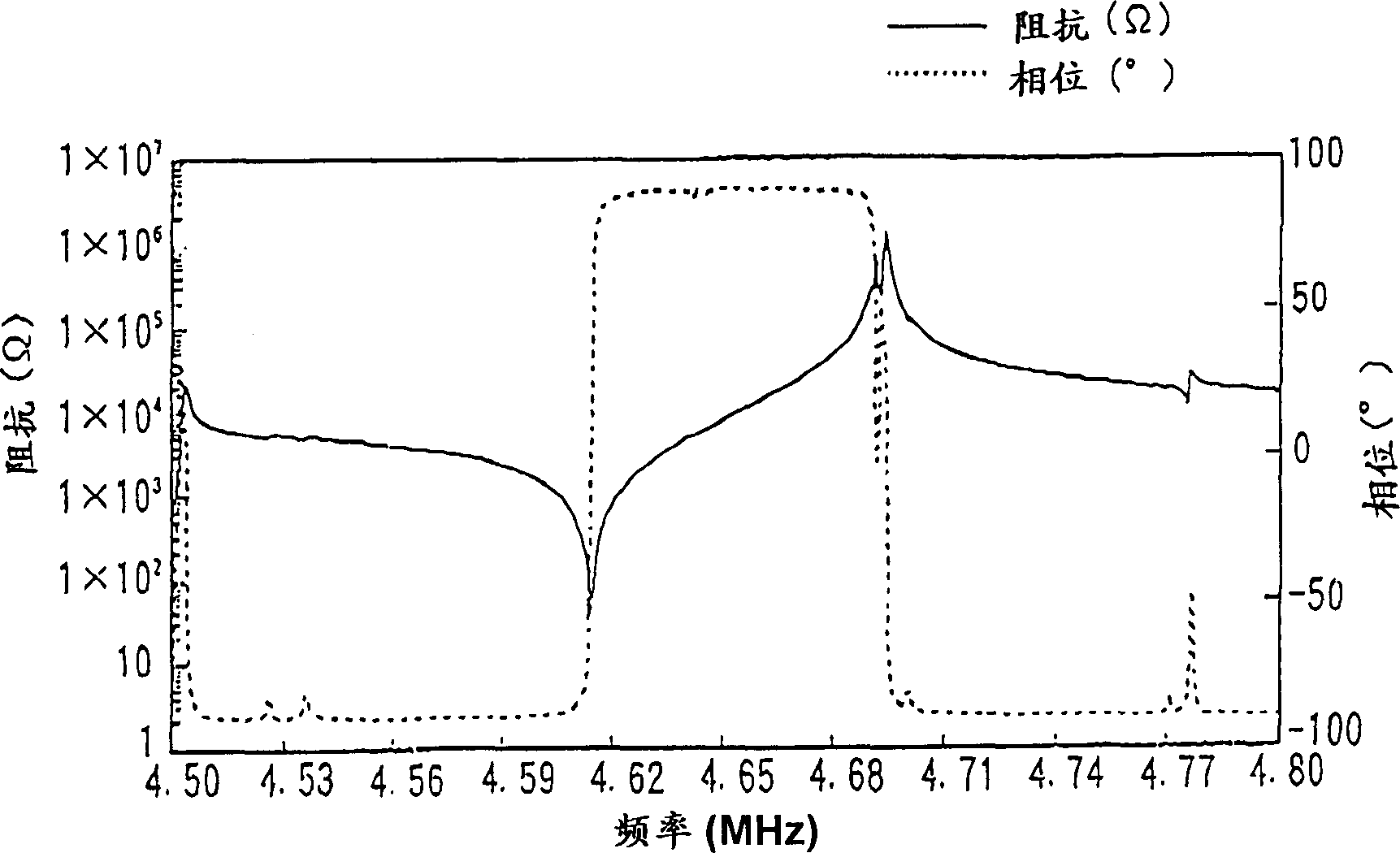

example 1

[0097] Examples of the present invention are described below.

[0098] As a starting material, bismuth oxide (Bi 2 o 3 ), lanthanum oxide (La 2 o 3 ), titanium oxide (TiO 2 ), strontium carbonate (SrCO 3 ) and manganese carbonate (MnCO 3 ) The raw material powder that constitutes, weigh the weight of said raw material to provide by (Sr 0.9 La 0.1 ) Bi 4 Ti 4 o 15 Composition, weigh the weight of manganese carbonate as (Sr 0.9 La 0.1 ) Bi 4 Ti 4 o 15 0.5% by mass. The weighed material was subjected to ball milling mixing with zirconia spheres in pure water for about 15 hours. The mixed raw material powder was completely dried by pressing at a temperature of 800° C. and the raw material was calcined. Subsequently, the calcined material was again subjected to ball mill pulverization, dried and granulated by adding an appropriate amount of polyvinyl alcohol as a binder. After granulation, the granulated powder was formed on a sheet of length 20 mm x width 20 mm x...

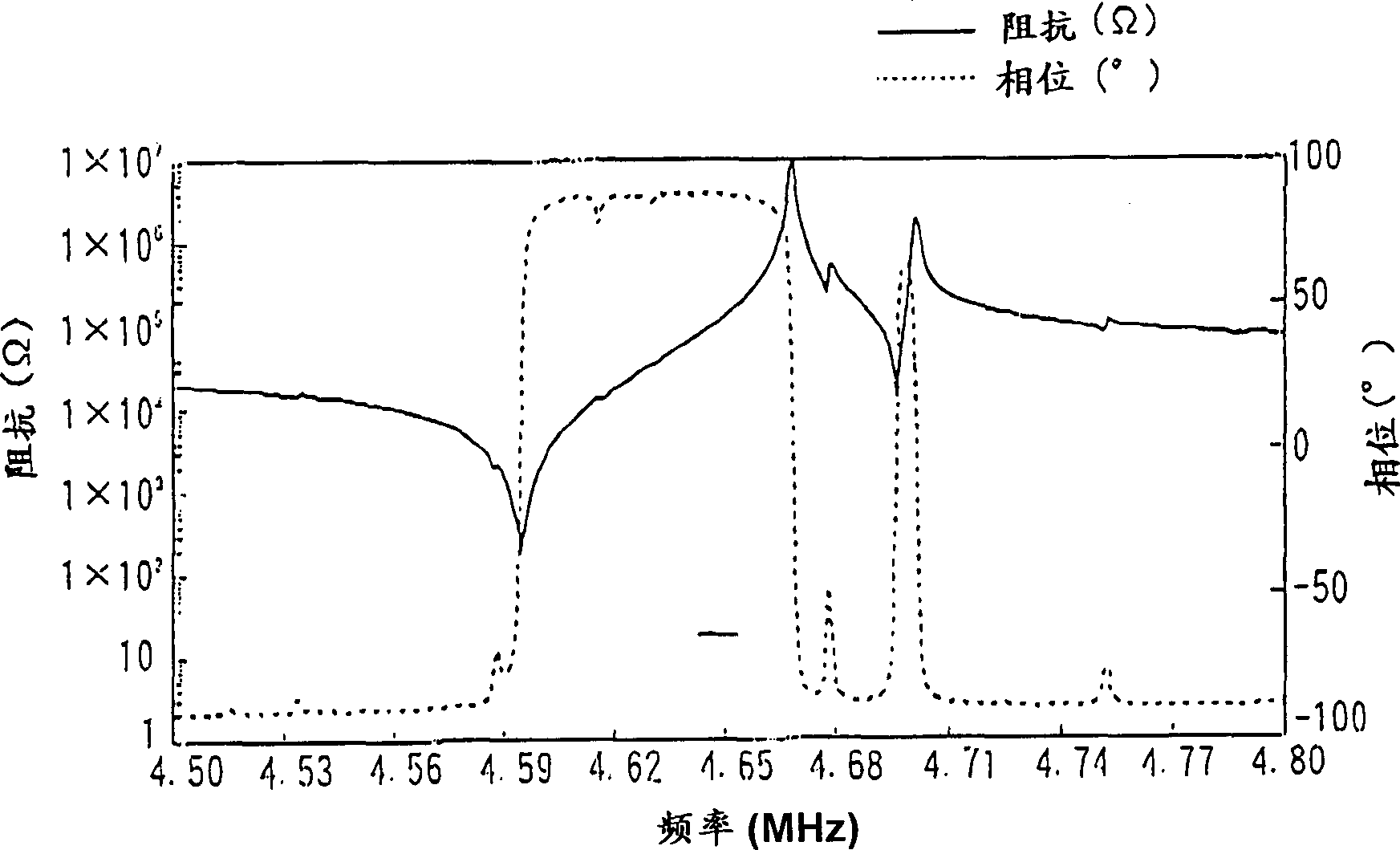

no. 2 example

[0122] A second embodiment of the present invention will be described below with reference to the drawings.

[0123] Fig. 6 is a perspective view schematically showing the structure of a piezoelectric resonator according to a second embodiment of the present invention. The piezoelectric resonator includes: a piezoelectric base 1 with a pair of opposite surfaces 1a and 1b and an effective Poisson's ratio smaller than 1 / 3; The opposite surfaces 1a, 1b correspond. This structure is similar to that of the first embodiment.

[0124] The opposite surfaces 1a, 1b of the piezoelectric base layer 1 have almost the same shape, such as a rectangle, respectively. A rectangular shape as referred to herein is a substantially sensed shape. So, slightly off corners or corners that are not exactly 90 degrees are allowed. The length Lc of one side of the opposite surfaces 1a, 1b is limited to the distance between the opposite surfaces 1a, 1b as shown in Equation 2-1, ie, 5 times or less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com