Aqueous dispersion composition for imparting chipping resistance

A water-based dispersion, anti-fragmentation technology, applied in the direction of unspecified rubber coatings, coatings, primers, etc., can solve the difficulty of anti-fragmentation of coating films, reduce the cross-linking density of cross-linked coatings, and the strength of coating films , Hot water resistance, damage resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0112] Aqueous dispersion containing ethylene / propylene copolymer (a)-1 and carboxylic acid-modified thermoplastic polymer (b-1) preparation of body composition

[0113] 100 parts by weight of ethylene / propylene copolymer (elastomer with ethylene / propylene molar ratio of 4 / 6, MFR (230°C): 2.0g / 10min), 10 parts by weight of maleic anhydride-modified polyethylene wax (grafted Amount: 3% by weight, -COO- group: 0.67 mmol / g polymer, [η] (135°C, solvent: decahydronaphthalene): 0.16 dl / g) and 2 parts by weight of potassium oleate were mixed. With the rate of 3000g / h, this mixture is fed into twin-screw extruder (Ikegai Tekkosho PCM-30, L / D=40) by the hopper of twin-screw extruder, simultaneously, 10% potassium hydroxide aqueous solution is mixed with 240g The rate of / h is continuously fed from the feed port installed in the exhaust section of the extruder, and then the resin mixture is continuously extruded at a heating temperature of 230°C. The resin mixture extruded in this ...

preparation Embodiment 2

[0115] Aqueous dispersion containing ethylene / octene copolymer (a)-2 and carboxylic acid modified thermoplastic polymer (b-1) preparation of body composition

[0116] In the same manner as described in Preparation Example 1, an aqueous dispersion composition having a solids concentration of 45%, a pH of 10, and an average particle size of 0.3 μm was obtained with a 99% yield, except that ethylene / octene copolymer (ethylene Elastene / octene molar ratio of 85 / 15, MFR (230°C): 150 g / 10min) to replace ethylene / propylene copolymer.

preparation Embodiment 3

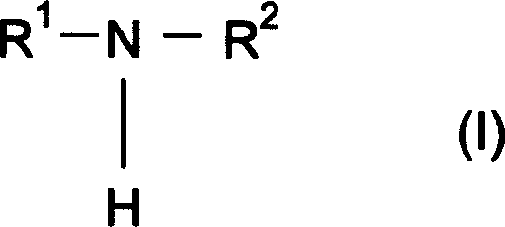

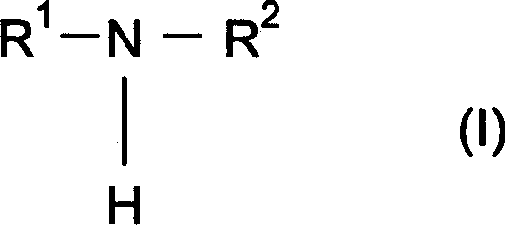

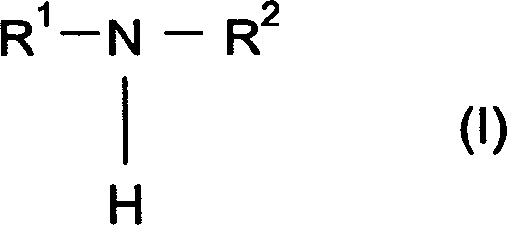

[0118] Containing ethylene / propylene and its polymer (a)-1, carboxylic acid modified thermoplastic polymer (b-1) and 2-(2-amino Preparation of an aqueous dispersion composition of ethyl ethoxy)ethanol (c)

[0119] Add 2-(2-aminoethoxy)ethanol (purchased from Huntsman, Diglycolamine) to the aqueous dispersion composition prepared in Preparation Example 1 to obtain a solid concentration of 44.8%, a pH of 10.5, and an average particle size of 0.8 For an aqueous dispersion composition of μm, the amount of 2-(2-aminoethoxy)ethanol added is 1% by weight, based on 100% by weight of the resin solid content in the aqueous dispersion composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com