Electric soldering iron tip and electric soldering iron

A technology of soldering iron tips and electric soldering irons, applied to soldering irons, soldering positions, coatings, etc., can solve problems such as difficult temperature control of temperature differences, deterioration of heat conduction, short circuits, etc., and achieve improved oxidation resistance, excellent oxidation resistance, and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0018] According to yet another preferred embodiment of the third soldering iron tip for an electric soldering iron of the present invention, the aforementioned first member is fixed on the front end of the substantially cylindrical tubular member.

[0019] In addition, the above-mentioned soldering iron tip of the present invention is characterized in that the surface of the soldering iron tip of a soldering iron made of copper or copper alloy is modified into a Cu-Al alloy coating layer with a high Al concentration, and the surface is formed with aluminum oxide (Al 2 o 3 ) of the firm film, endowed with oxidation resistance at high temperatures.

[0020] A brief description of the drawings

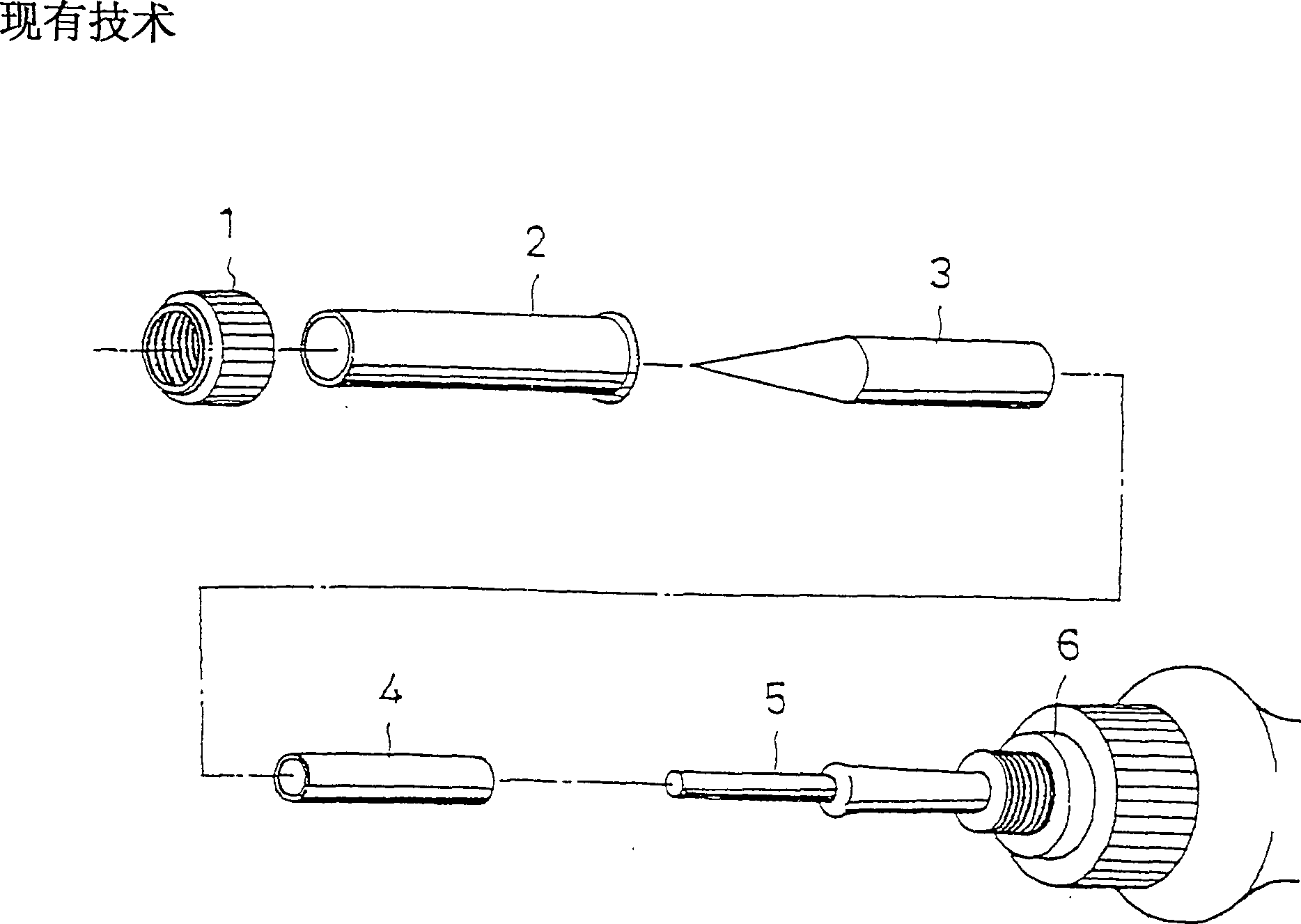

[0021] figure 1 It is an exploded perspective view showing the structure of a conventional electric soldering iron.

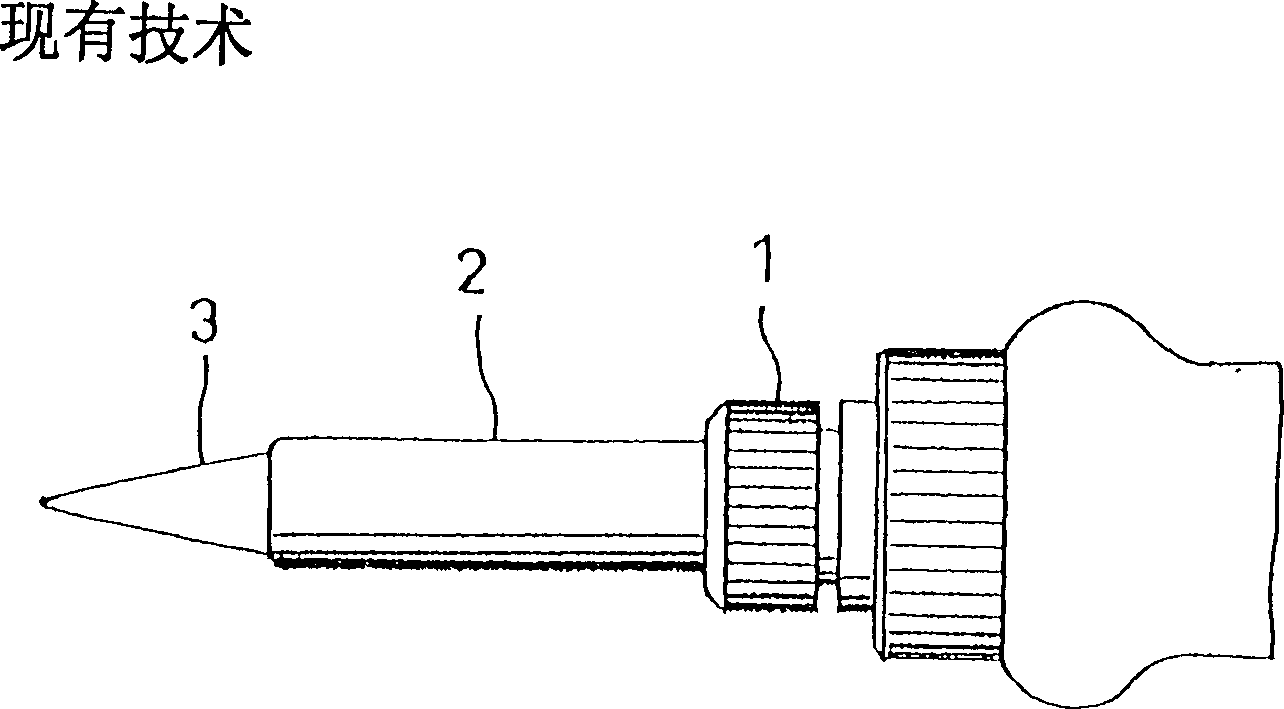

[0022] figure 2 yes means figure 1 An illustration of the assembled state of the soldering iron.

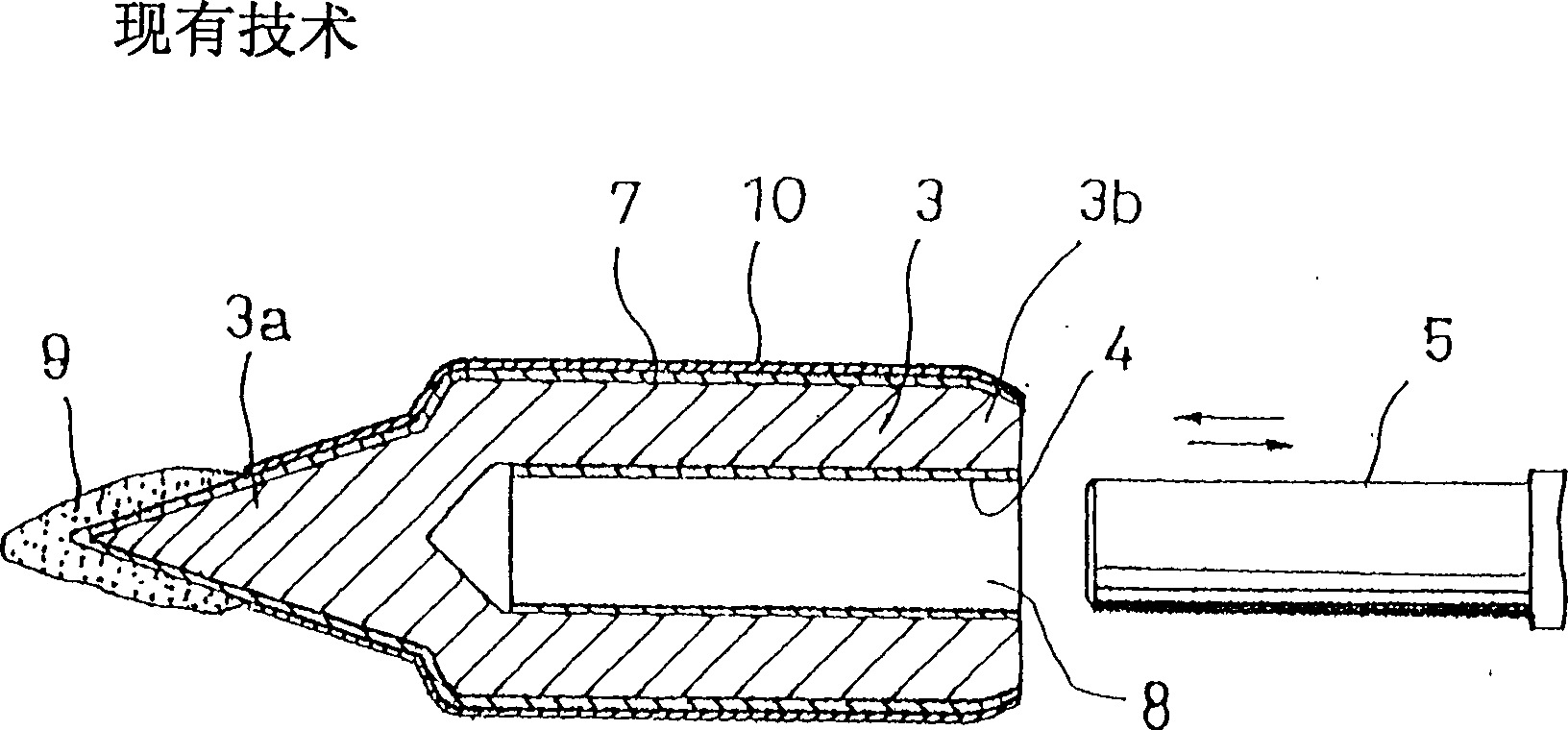

[0023] image 3 It is a schematic cross-sectional view of a sol...

Embodiment 1

[0050] The scope of application of the surface modification method of the present invention is to replace the chrome plating of the soldering iron tip in the prior art. Or on the inner surface portion of the barrel portion 8 where the copper material of the copper soldering iron tip is exposed. In the prior art, this part is protected with an inner tube 4 . The soldering iron tip 3 used in this embodiment is a pure copper material, and its size and shape are shown in Figure 5 .

[0051] First, the surface modification of the chrome-plated portion that has been used in the past will be described. Image 6 This is an example thereof. In this example, a partial iron plating layer 7 is formed in advance on the front end portion 3 a of the soldering iron tip 3 . The purpose of plating the iron layer 7 on this part is, as mentioned above, to prevent the copper or copper alloy as the raw material of the soldering iron tip 3 from being corroded by the solder, and it is not necessa...

Embodiment 2

[0054] The surface modification of the inner surface of the barrel portion 8 of the copper tip 3 will be described below. The main reason why this part has not been improved so far is that there are technical difficulties in chrome plating to increase oxidation resistance. The following will be described using examples.

[0055] The shape of the sample is the same as in the example, but the diameter of the cylindrical part is 4.2 mm and the depth is 23 mm.

[0056] Figure 7 It means that in this example, the mixture of Al particles and fluoride-based flux was coated on the outer peripheral surface of the soldering iron tip 3 in the same way as in part 10-1 of Example 1, and then evenly coated The inner surface of the barrel portion 8 was then heat-treated under the same conditions as in Example 1 to obtain a surface-modified layer 10-2. After the treatment, in order to observe the state of the inner surface, the sample was cut in half, and the results were observed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com