Paving material and paving prefabric member, and their producing method

A technology of pavement materials and prefabricated parts, which is applied to pavements, pavements, buildings and other directions paved with prefabricated blocks, which can solve the problems of short circuit of electrical appliances and power supply, inability to use greening, difficult operation and use, etc., and achieve simplified manufacturing procedures and water permeability Good performance and resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

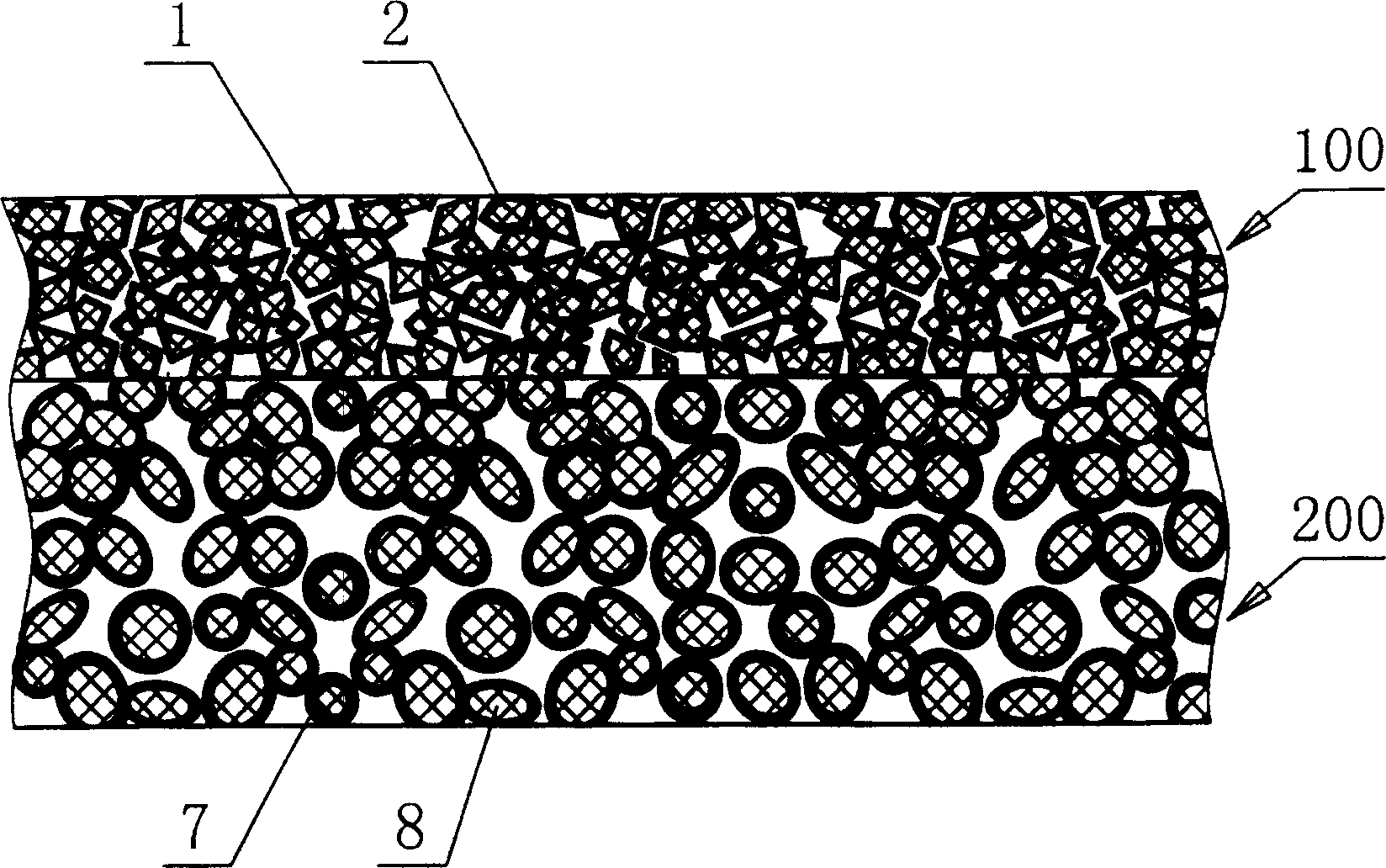

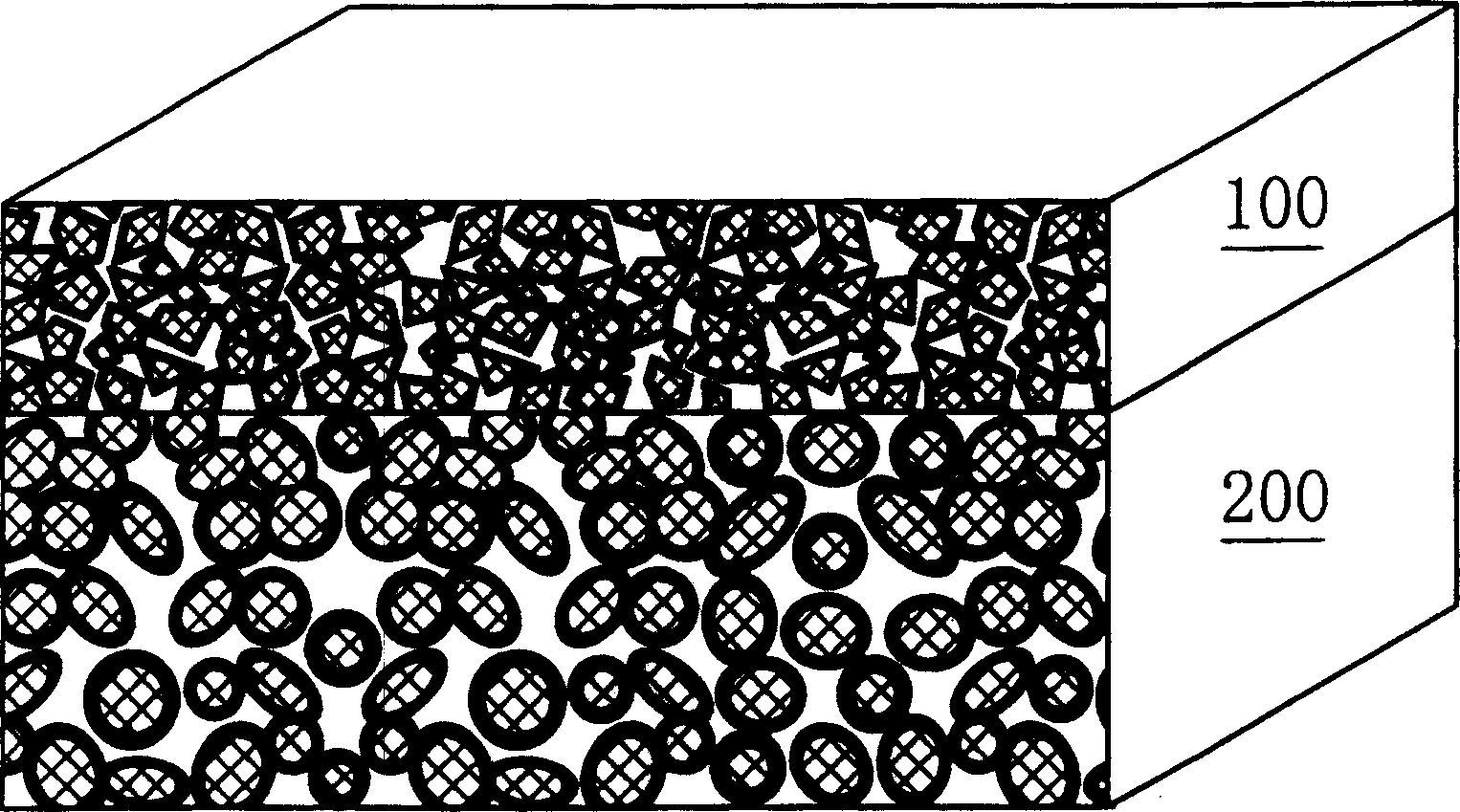

[0036] Embodiment 1 (paving prefabricated parts)

[0037] Mix polyurethane resin, glass fiber and rock wool at a weight ratio of 8:0.5:1.5 for stirring, adjust the viscosity to a range of 1-3 Pa.s, and then mix with a curing agent at a ratio of 10:1. Then one or two of the following (sand, machine crushed stone, gravel, stone powder, bean stone and other aggregates or urban waste, construction waste, waste slag, scrap steel slag, waste rubber, waste plastic, coal gangue, red Gangue, waste sawdust, broken glass and sludge from rivers or sewers) are mixed in a weight ratio of 90% and stirred together, and then poured into a mold of 25cm×25cm×6cm to make a surface layer. Mix 2% magnesium chloride, 90% calcium chloride, 8% potassium carbonate, etc. with water at a ratio of 1:9 to form a liquid, then add 0.43 kg of cement at the bottom layer, adjust the water-cement ratio W / C between 0.3 and 0.6, and adjust it to 4.3 kg crushed stone, pea stone or other aggregates are stirred and ...

Embodiment 2

[0038] Embodiment 2 (paving material)

[0039] On the foundation surface of the road, first mix 2% magnesium chloride, 90% calcium chloride, and 8% potassium carbonate with water at a ratio of 1:9 and add them to 8% to 15% of the total weight of the bottom layer of the road cement in liquid form, and then mix with machine crushed Stones, bean stones or other aggregates are stirred and paved to form the bottom layer of the ground. (The amount of crushed stone, bean stone or other aggregates can be determined according to the size and thickness of the ground). The surface layer of the ground is formed in this way, that is, epoxy resin, glass fiber and rock wool are mixed together at 8:0.5:1.5 and stirred, and the viscosity can be adjusted to the range of 1-3Pa.s, and then connected with 3:1 Mix with curing agent, and then add one or two of the following (sand, machine crushed stone, gravel, stone powder, bean stone and other aggregates or urban waste, construction waste, waste ...

Embodiment 3

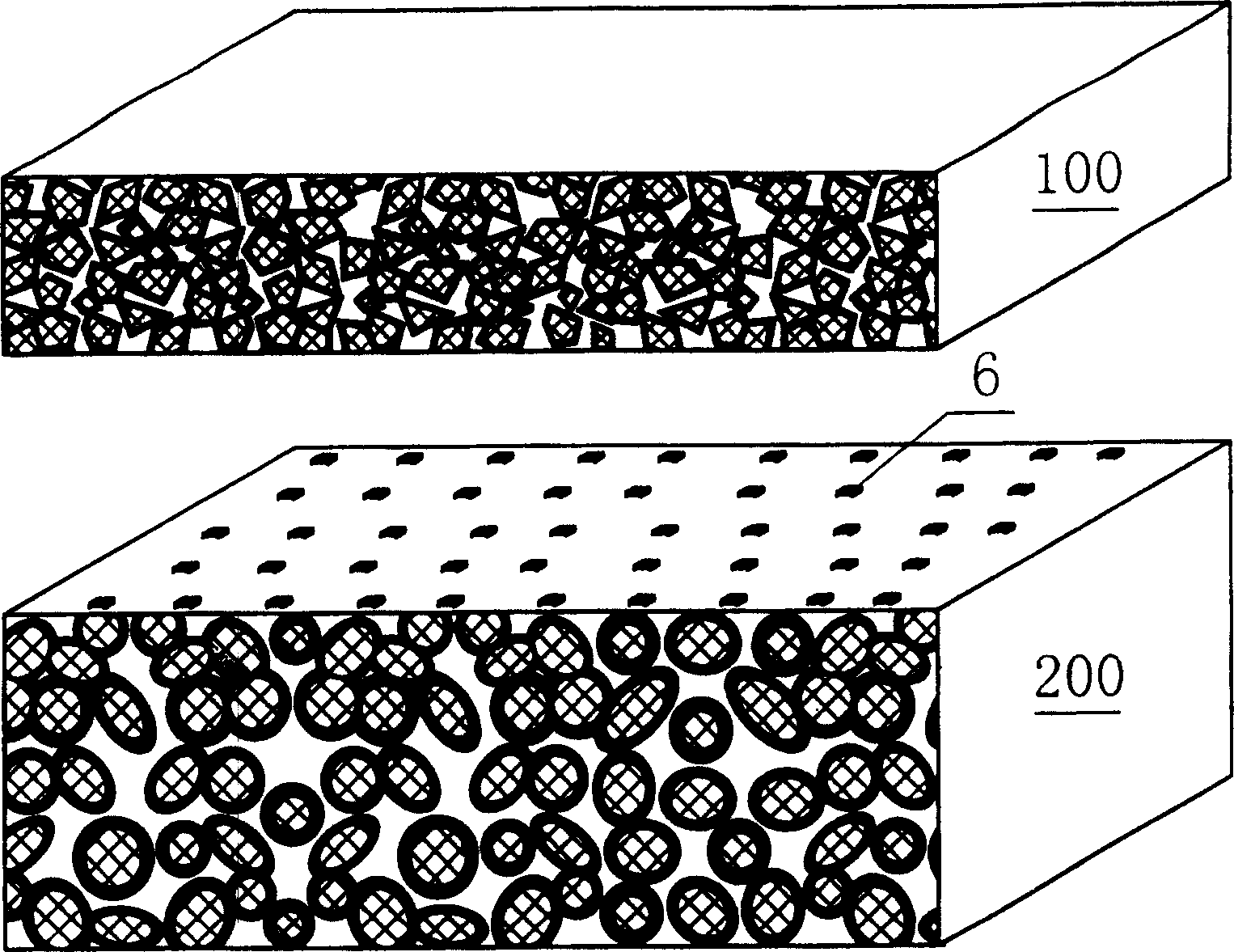

[0040] Embodiment 3 (pavement prefabricated part for greening)

[0041] according to figure 1 , mix acrylic resin with glass fiber and rock wool (according to 8:0.5:1.5) and stir together, adjust the viscosity to the range of 1-3Pa.s, then add 10% curing agent and mix, and then mix one or both of the following Kinds (sand, machine crushed stone, gravel, stone powder, bean stone and other aggregates or urban waste, construction waste, waste slag, coal gangue, red gangue) are mixed and stirred at a weight ratio of 10:1, poured into In the mold of 46cm * 26cm * 2cm, after paving and compacting, sprinkle herbal seeds on it, then mix 2% of magnesium chloride, 90% of calcium chloride, 8% of potassium carbonate with water to be liquid, add Add 5.2kg of cement that accounts for 6% to 8% of the total weight, then mix with 5.2kg of machine crushed stone, pea stone or other aggregates, pour it into the surface layer mold with herb seeds, and cover it Above the herbaceous plant seeds, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com