Zero-pollution dry domestic-animal-fowl raising method and apparatus

A dry technology for livestock and poultry, which is applied in the field of livestock and poultry breeding, can solve problems such as increased feeding costs, pollution, and long fermentation time, and achieve the effects of improving environmental sanitation and environmental quality, improving metabolic efficiency, and improving metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

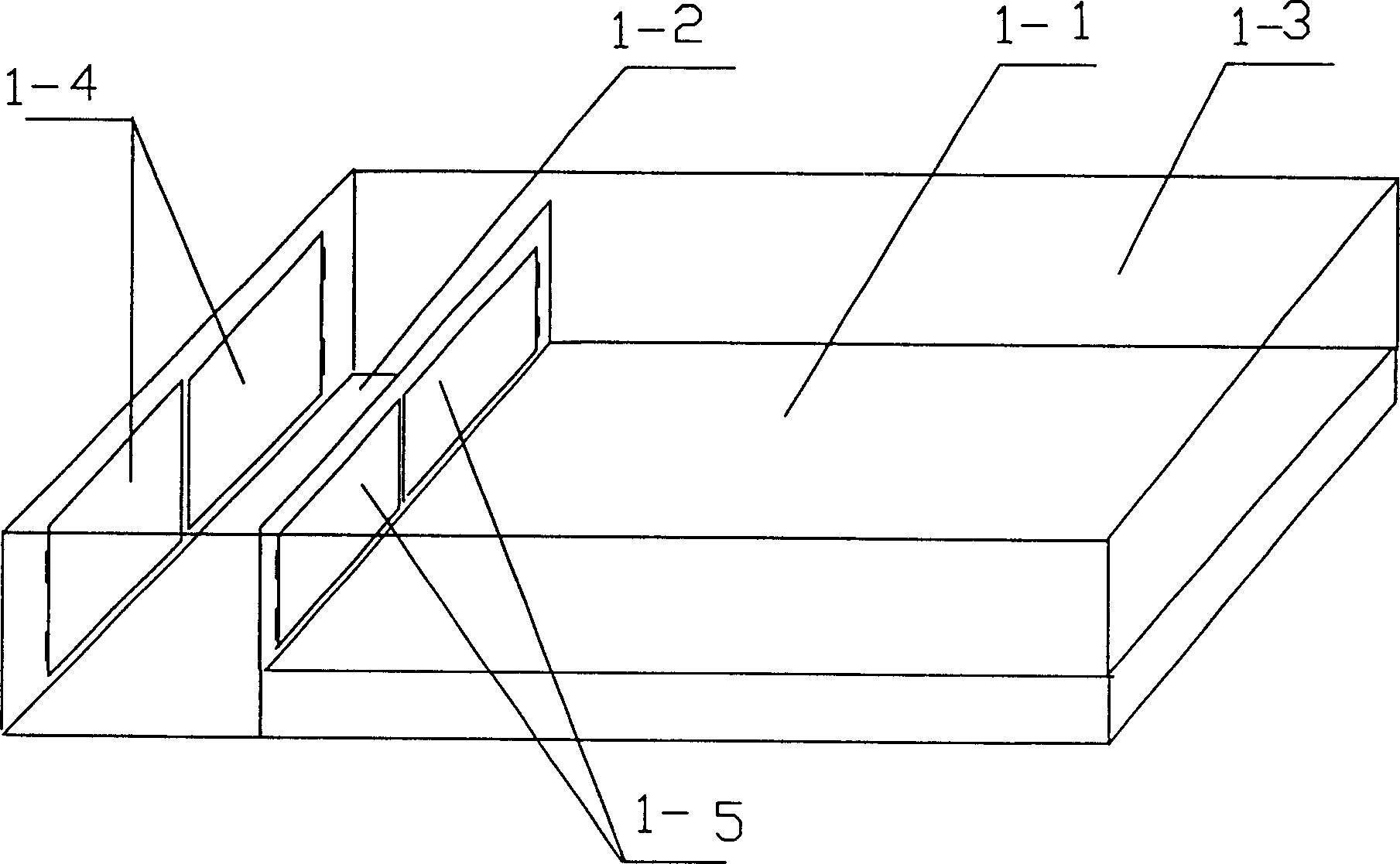

[0051] refer to figure 1 , a preferred embodiment of the dry livestock and poultry breeding method of the present invention can be applied to pig breeding. First of all, the pig house includes the breeding area and the fence 1-3 that defines the breeding area. The breeding area is divided into a rest area 1-1 and an excretion area 1-2. The defecation area is lower than the rest area. H=15-20cm. The fence on the side of the area has doors 1-4 for removing excrement, and doors 1-5 are arranged at the boundary between the rest and activity area and the defecation area.

[0052] The bedding is laid in the defecation area. In step 1 of laying the bedding, the bedding is first sterilized by photocatalyst disinfection to eliminate unknown bacteria (such as rhizobia, actinomycetes, etc.) contained in the bedding , Effectively avoid bringing harmful foreign bacteria into the farm house (that is, the pig house). Lay sterile litter with a humidity of about 20-25% evenly on the ground o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com