Ultrathin pinless packaging process of integrated circuit and discrete component and its packaging structure

A discrete component, integrated circuit technology, applied in the field of integrated circuit or discrete component ultra-thin leadless packaging process and its packaging structure, can solve the problems of rigid arrangement, high electroplating cost, discount on utilizability, etc., achieve high transmission and heat dissipation, The effect of low material cost and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

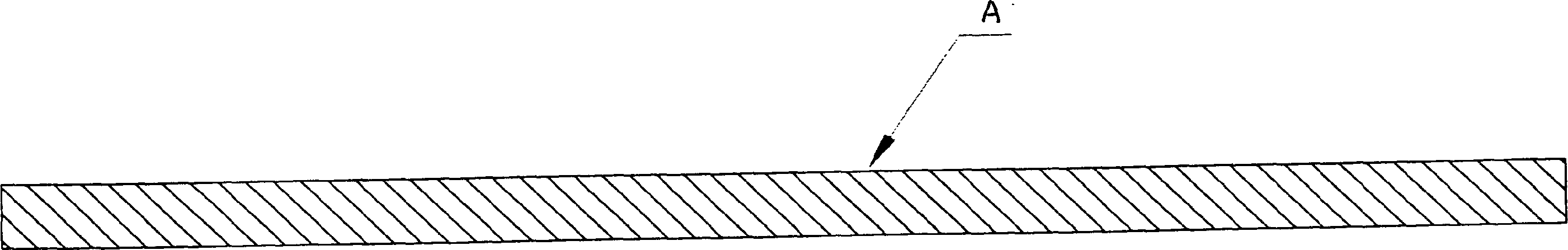

[0046] 1) see figure 1 , take a piece of metal substrate A of suitable thickness. The material of the metal substrate can be changed according to the function and characteristics of the chip, such as: alloy or copper;

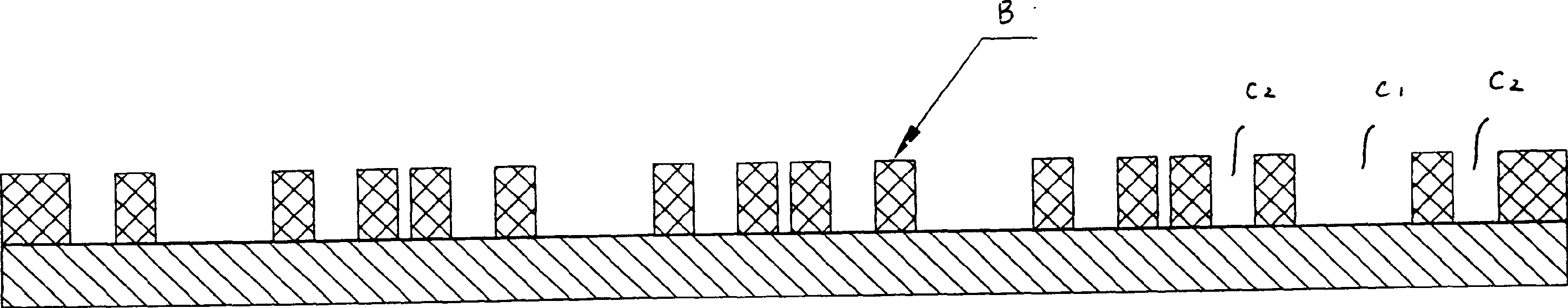

[0047] 2) see figure 2 , Dry ink B coating is carried out on the metal substrate A. The area on the metal substrate that is not coated with dry ink forms the chip area C1 and the inner foot area C2 for wiring;

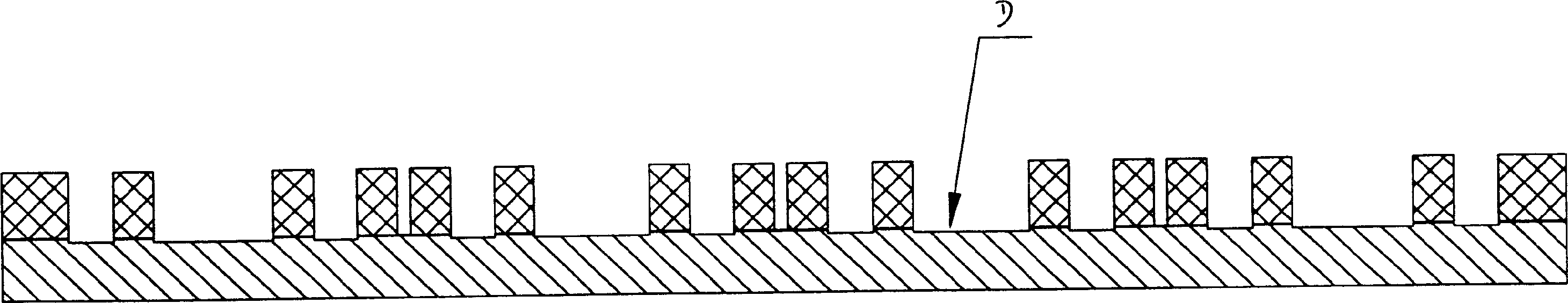

[0048] 3) see image 3 , etching the chip area C1 and the inner foot area C2 of the wire bonding on the metal substrate D;

[0049] 4) see Figure 4 , sputtering a layer of pure metal layer 1 on the metal substrates A1 and A2 in the chip area C1 and the wire-bonding inner foot area C2;

[0050] 5) see Figure 5 , on the pure metals 11 and 12 in the chip area C1 and the wire-bonding inner pin area C2, a layer of metal activation layer 2 is sputtered, such as an aluminum layer or a nickel, titanium, silver, or gold layer;

[0051] 6) see Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com