Synthesis method for cadmium selenide and cadmium telluride quantum dot

A technology of cadmium telluride quantum dots and cadmium selenide, which is applied in the field of solvothermal synthesis of cadmium selenide and cadmium telluride quantum dots, can solve the problems of unfavorable large-scale industrial production and wide size distribution, and reduce energy consumption , simple operation and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

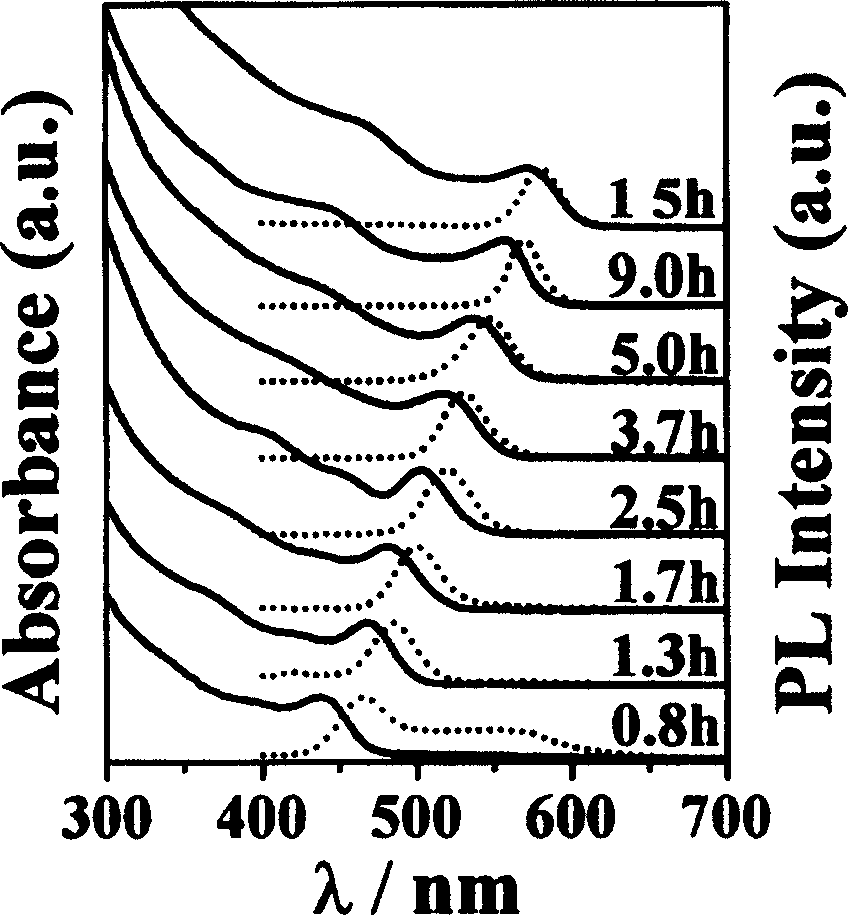

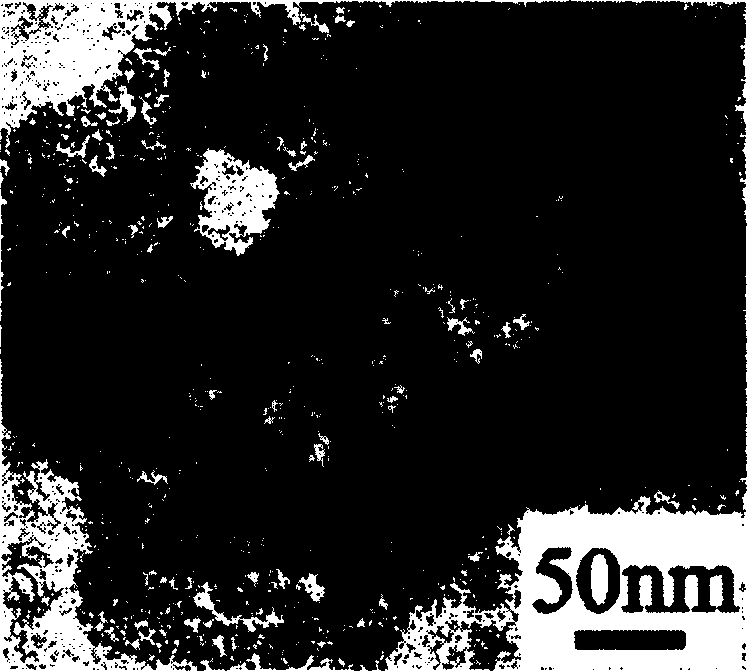

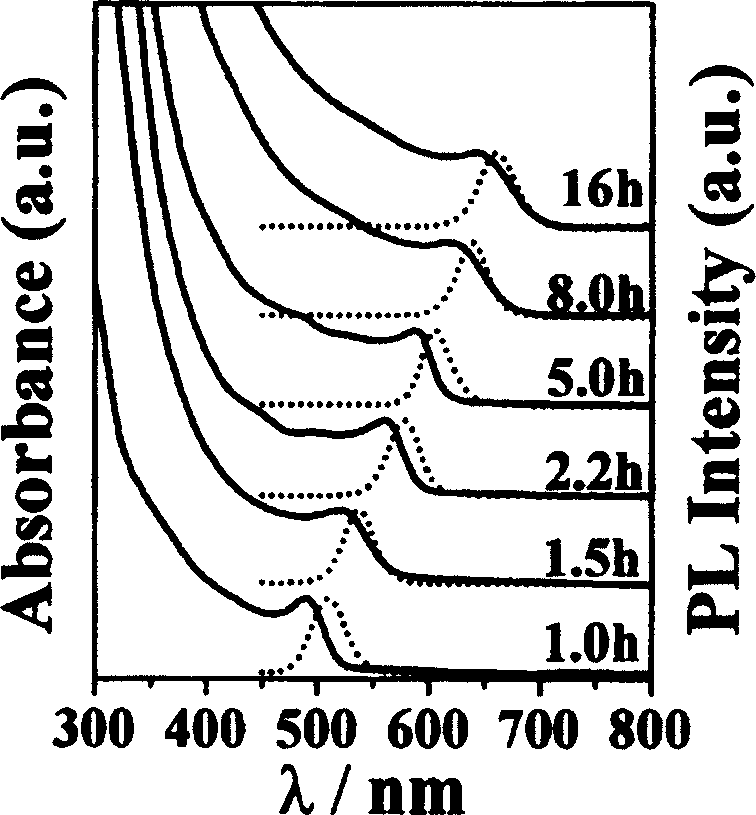

[0013] Heat the mixture of 0.1mmol (0.0235g) cadmium acetate, 0.6mmol (0.2320g) TOPO and 20ml benzene at a temperature of 90±10°C until it is colorless and transparent. After cooling down to below 40°C, mix the solution with The solution of 0.05mmol (0.004g) selenium and 0.06g TOP is mixed and added together into a 30ml autoclave with Teflon lining, the autoclave is sealed and put into the furnace to heat at 160°C for 1 hour, after cooling, selenium Cadmium oxide quantum dot generation. The fluorescence emission peak position of its benzene solution at room temperature is around 521nm, and the half-maximum width is 31nm.

Embodiment 2

[0015] Heat a mixture of 1.0mmol (0.5671g) cadmium tetradecyl carboxylate, 3.2mmol (0.891g) oleic acid and 70ml toluene at a temperature of 90±10°C until it is colorless and transparent, and after cooling to below 40°C, Then this solution was mixed with a solution containing 5.0mmol (0.3948g) selenium and 4.3g TOP, and then they were added together into a 100ml autoclave with a polytetrafluoroethylene lining, and the autoclave was sealed and heated at 180°C for 10 hours in a furnace , after cooling, cadmium selenide quantum dots are formed. The fluorescence emission peak position of its toluene solution at room temperature is around 643nm, and the half-peak width is 26nm.

Embodiment 3

[0017] Heat the mixture of 0.6mmol (0.4071g) cadmium stearate, 1.2mmol (0.4640g) TOPO and 40ml cyclohexane at a temperature of 90±10°C until it is colorless and transparent, and after cooling to below 40°C, put This solution is mixed with a solution containing 0.6mmol (0.0474g) of selenium and 0.32g of TOP, and is added to a 50ml autoclave with a polytetrafluoroethylene liner. After that, cadmium selenide quantum dots are formed. The fluorescence emission peak position of its cyclohexane solution at room temperature is around 494nm, and the half-peak width is 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com