Process for preparation of self-spread high-temperature synthesizing low-cost diphase alpha/beta-sialon powder

A low-cost, self-propagating technology, used in the field of high-temperature self-propagating process synthesis powder, low-cost synthesis of complex α/β-sialon powder, can solve the problem of high cost, achieve loose structure, reduce impurity content, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

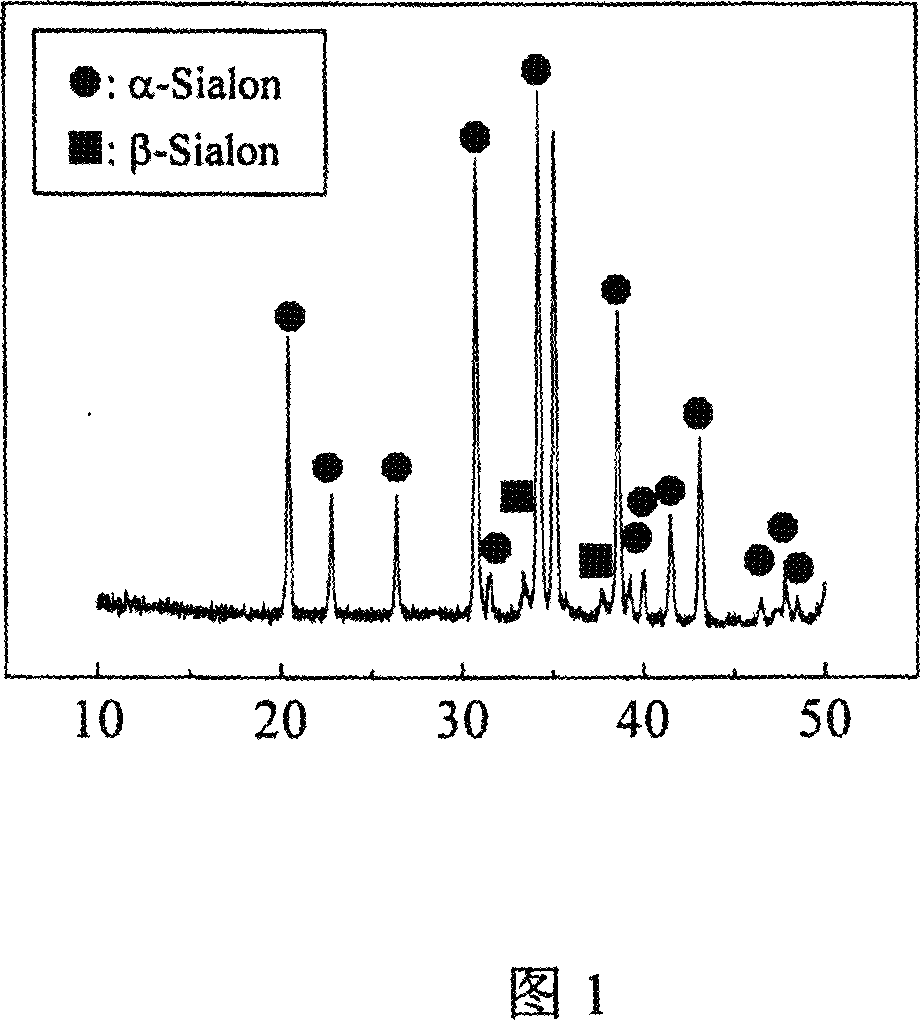

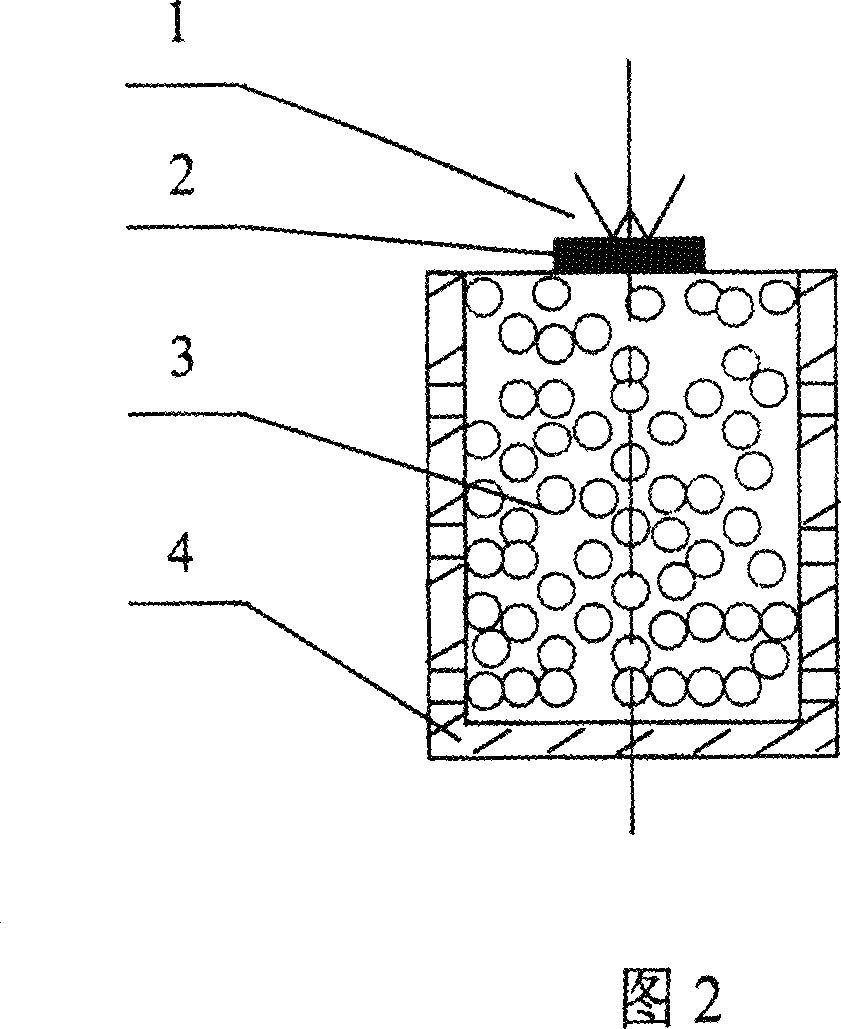

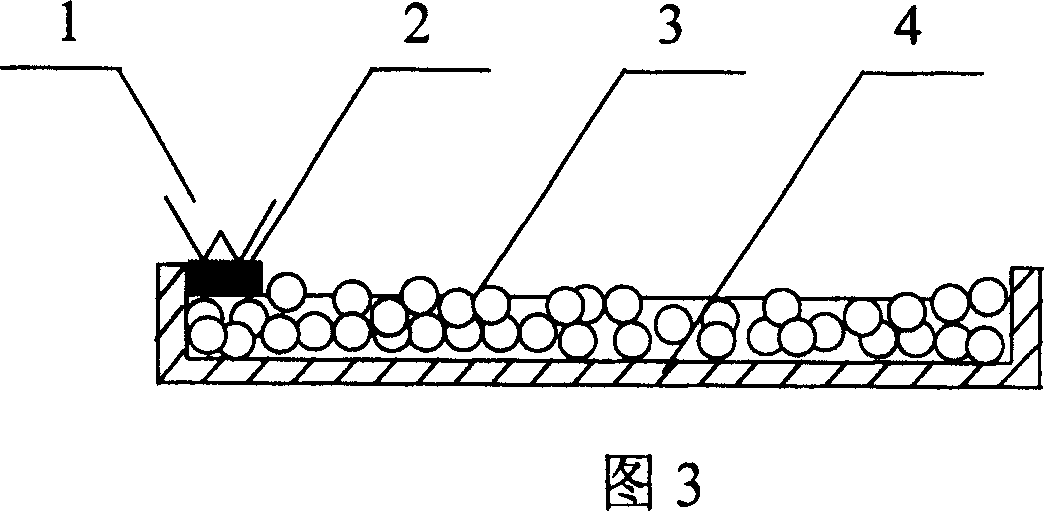

[0024] Using blast furnace slag, metallic silicon powder, and aluminum powder of a steel plant as raw materials, and adding a small amount of Sialon powder synthesized by the present invention, considering the chemical composition of the slag (Table 1), the composition of α-Sialon is based on Ca 0.71 Mg 0.23 Si 9.18 Al 2.82 o 0.94 N 15.06 Design, the composition of β-Sialon is according to SiO in silicon, aluminum and slag 2 and Al 2 o 3volume design. The raw materials prepared according to this component are mixed with silicon nitride balls as the medium in a nylon barrel, and after 24 hours of dry-mixed ball milling, they are loosely packed in an upright ring-shaped cylinder made of carbon felt with an outer diameter of 60mm x an inner diameter of 55mm x a height of 60mm (Fig. 1), put it into a self-propagating high-temperature synthesis furnace, and fill it with 3-15 MPa high-pressure nitrogen (purity 99.99%) after vacuuming, and the synthesis atmosphere is high-pres...

Embodiment 2

[0027] Adopt the same technique of embodiment 1, just replace blast furnace slag with dolomite powder instead, it and metal silicon powder, aluminum powder and 20% Sialon powder of the present invention synthesis make raw material, the component design of Ca-α-Sialon is in the whole Ca- Ca-α / β-Sialon can be synthesized by high-temperature self-propagating process due to changes in the α-Sialon phase region. Specifically, press M x Si 12-3x Al 3x o 2x N 16-2x Component design, any point in 0.4<x<1.4 can be selected. β-Sialon is designed according to the amount of silicon and aluminum. The rest of the conditions are the same as in Example 1, and the multi-phase (Ca, Mg)-α / β-Sialon powder is obtained.

Embodiment 3

[0029] Adopt the same technique of embodiment 1, just replace blast furnace slag with fly ash, limestone powder instead, it and metal silicon powder, aluminum powder and 20% Sialon powder synthesized by the present invention are made raw materials, the component design of Ca-α-Sialon Changing in the whole Ca-α-Sialon phase region, Ca-α / β-Sialon can be synthesized by high temperature self-propagating process. Specifically, press M x Si 12-3x Al 3x o 2x N 16-2x Component design, any point in 0.4<x<1.4 can be selected. β-Sialon is designed according to the composition of silicon, aluminum and fly ash. The rest of the conditions are the same as in Example 1, and a multi-phase Ca-α / β-Sialon powder is obtained.

[0030] SiO 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com