Microcarrier for large-scale culture cell

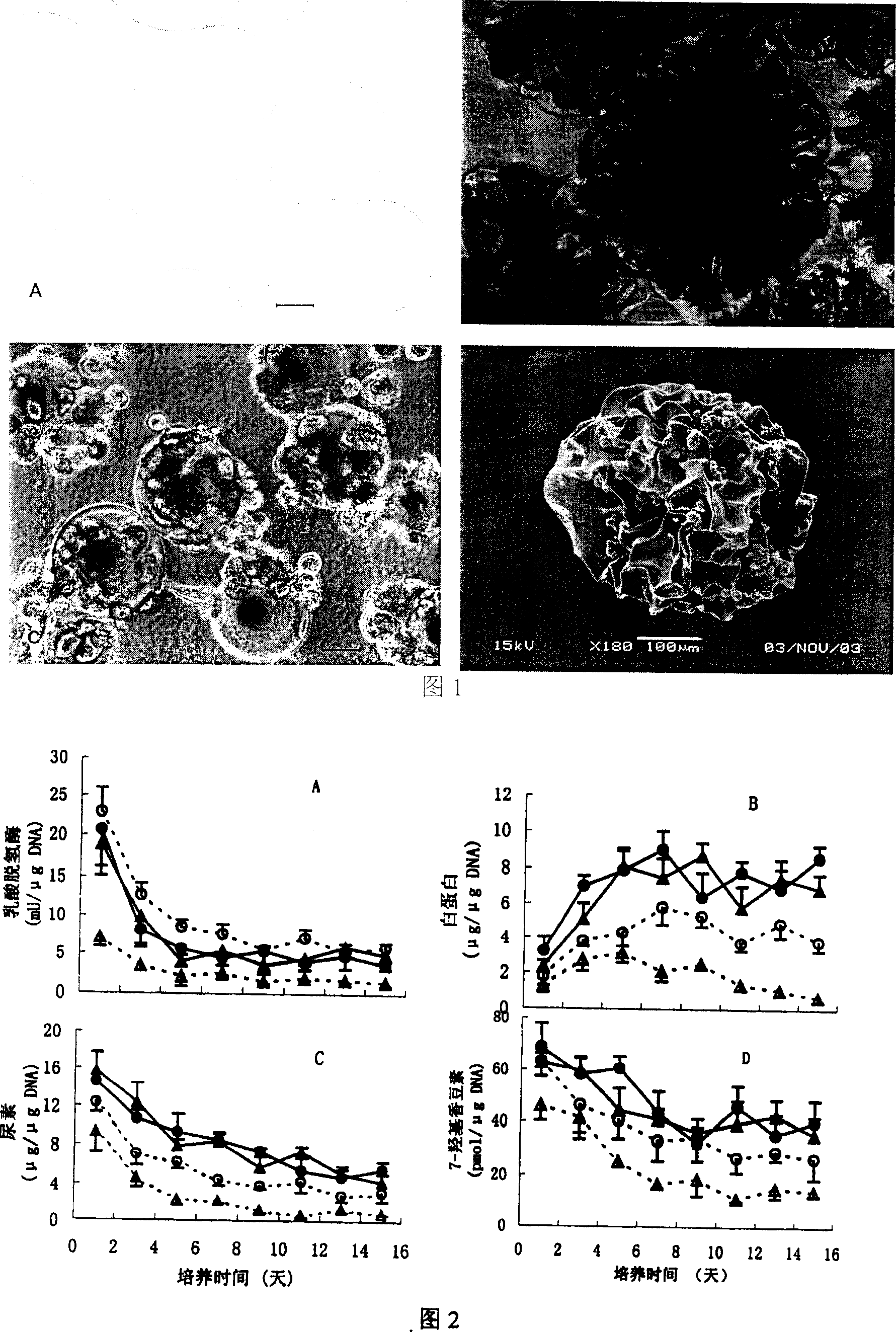

A large-scale culture, microcarrier technology, applied in tissue culture, tissue cell/virus culture devices, fixed on/in organic carriers, etc., can solve the problem of inability to take into account cell affinity and long-term maintenance of cell function, etc. It is suitable for large-scale culture, maintains metabolic activity, and has low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1, solid microcarrier I

[0042] Prepare 1w / v% chitosan acetic acid aqueous solution and 1w / v% gelatin aqueous solution, the two are mixed uniformly at 50 ℃ by 1: 3 volume ratio, be prepared into composite chitosan-gelatin aqueous solution; Under 300rpm mechanical stirring, Add 3 volumes of mineral oil containing 0.5w / v% Span 40 to this solution, and stir for 5 minutes to form a stable chitosan-gelatin water-in-oil agent; add 0.1w / v% pentadiene while stirring Aldehyde, continue to stir for 0.5 hours, and then stand still for 0.5 hours to obtain the aqueous phase solidified with glutaraldehyde as a crosslinking agent; filter with a 100 / 280 μm pore size sieve to collect microcarriers with a diameter of 100 to 280 μm to obtain solid microcarriers ; Wash with surfactant Tween to remove the oil phase on the surface of the carrier; then treat with 0.01M glycine for 30 hours to block unreacted aldehyde groups; then treat with 0.1w / v% NaOH for 10 h...

Embodiment 2

[0043] Embodiment 2, the preparation of solid microcarrier II

[0044] Prepare 5w / v% chitosan acetic acid aqueous solution and 5w / v% gelatin aqueous solution, the two are mixed uniformly at 70 ℃ by 3: 1 volume ratio, be prepared into composite chitosan-gelatin aqueous solution; Under 500rpm mechanical stirring, Add 10 times the volume of this solution to mineral oil containing 5w / v% Span 60, stir for 30 minutes to form a stable chitosan-gelatin water-in-oil agent; add 10w / v% glutaraldehyde while stirring, Continue to stir for 5 hours, and then stand still for 5 hours to obtain an aqueous phase solidified with glutaraldehyde as a cross-linking agent; filter through a sieve with a pore size of 100 / 280 μm, and collect microcarriers with a diameter of 100 to 280 μm to obtain solid microcarriers; Wash with petroleum ether to remove the oil phase on the surface of the carrier; then treat with 0.5M glycine for 2 hours to block unreacted aldehyde groups; then treat with 10w / v% NaOH fo...

Embodiment 3

[0045] Embodiment 3, the preparation of solid microcarrier III

[0046] Prepare 3w / v% chitosan acetic acid aqueous solution and 3w / v% gelatin aqueous solution, the two are mixed uniformly at 60 ℃ by 1: 1 volume ratio, be prepared into composite chitosan-gelatin aqueous solution; Under 400rpm mechanical stirring, Add 8 times the volume of mineral oil containing 2.5w / v% Span 85 to this solution, and stir for 20 minutes to form a stable chitosan-gelatin water-in-oil agent; add 5w / v% glutaraldehyde while stirring , continue to stir for 2 hours, and then stand still for 2 hours to obtain an aqueous phase solidified with glutaraldehyde as a crosslinking agent; filter with a sieve with a pore size of 100 / 280 μm, and collect microcarriers with a diameter of 100 to 280 μm to obtain solid microcarriers; Wash with acetone to remove the oil phase on the surface of the carrier; then treat with 0.2M glycine for 15 hours to block unreacted aldehyde groups; then treat with 4w / v% NaOH for 5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com