Environment-friendly rosin-modified phenolic resin and preparation method thereof

A phenolic resin, rosin modification technology, applied in inks, household appliances, applications, etc., to achieve the effects of controllable reaction process factors, less side reactions, and complete reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Embodiment 1: A kind of preparation method of environment-friendly type rosin modified phenolic resin

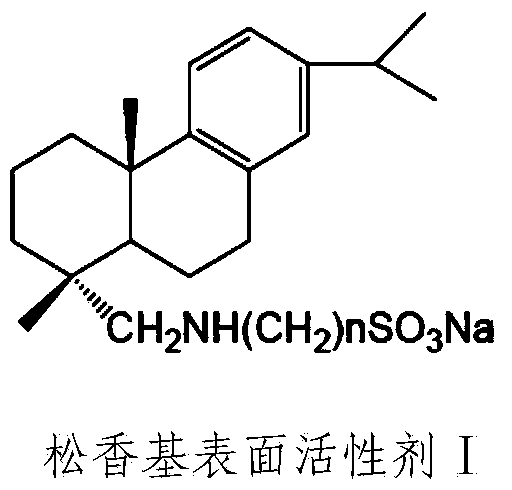

[0094] 1. Raw material pretreatment process: under the condition of nitrogen protection, heat masson pine pine resin to melt, filter, add 3‰ of rosin decolorizing agent oxalic acid, wash with water to remove dark water-soluble matter, obtain light color after clarification and separation Rosin raw material, after it is melted, add rosin-based surfactant A of 3‰ of rosin quality, stir evenly, cool to obtain the pretreated rosin raw material, for subsequent use;

[0095]

[0096] 2. Synthesis process of phenolic resin pulp: use phenol and formaldehyde with a molar ratio of 1:1 as raw materials for synthesizing phenolic pulp, add alkaline NaOH with a mass fraction of 0.5% of phenol, and react at 55°C for 2 hours to obtain phenolic resin pulp for later use;

[0097] 3. Alkali-treated titanium dioxide, which is prepared by the following method: dissolving titanium dioxi...

Embodiment 2

[0100] Embodiment 2: a kind of preparation method of environment-friendly type rosin modified phenolic resin

[0101] 1. Raw material pretreatment process: under the condition of nitrogen protection, after melting the first-grade rosin, add rosin-based surfactant B of 3‰ of the rosin quality, stir evenly, cool down, and obtain the pretreated rosin raw material for use;

[0102]

[0103] 2. Phenolic resin pulp synthesis process: use phenol and formaldehyde with a molar ratio of 1:1 as raw materials for synthesizing phenolic pulp, add alkaline NaOH with 1% phenol mass fraction, and react at 50°C for 3 hours to obtain phenolic resin pulp for later use;

[0104] 3. Alkaline treatment of titanium dioxide, which is prepared by the following method: dissolve titanium dioxide in a sodium hydroxide solution with a mass fraction of 30 times 10 mol / L, treat it at 160°C for 2 hours, wash with water to remove alkalinity, and then dry to obtain alkali Chemically treated titanium dioxide,...

Embodiment 3

[0107] Embodiment 3: A kind of preparation method of environment-friendly type rosin modified phenolic resin

[0108] 1. Raw material pretreatment process: heat masson pine rosin under nitrogen protection until it melts, filter, add 5‰ of rosin decolorizer oxalic acid, wash with water to remove dark water-soluble matter, obtain light-colored rosin after clarification and separation Raw material, after melting it, add rosin-based surfactant C of 3.5‰ of rosin quality, stir evenly, cool to obtain pretreated rosin raw material, and set aside;

[0109]

[0110] 2. Phenolic resin pulp synthesis process: use phenol and formaldehyde with a molar ratio of 1:1 as raw materials for synthesizing phenolic pulp, add alkaline NaOH with a phenol mass fraction of 0.6%, and react at 60° C. for 3 hours to obtain phenolic resin pulp for later use;

[0111] 3. Esterification functionalization reaction process: under the protection of nitrogen, add the pretreated rosin raw material obtained in ...

PUM

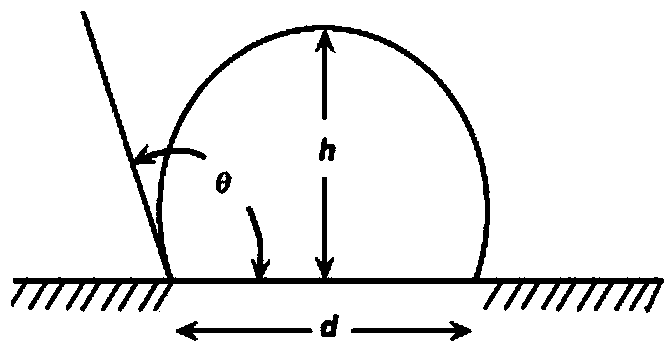

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com