Method for magnesia nanometer line epitaxial growth from strontium titanate monocrystal chip

A technology of strontium titanate substrate and nano-film, which is applied in the field of microelectronic materials, can solve problems such as difficulty in structural control, and achieve the effect of enhancing quantum effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The magnesium oxide nano film with ordered surface periodic structure prepared by the present invention is to use laser molecular beam epitaxy (L-MBE) to ablate and peel off the magnesium oxide ceramic target material on the strontium titanate (001) single crystal substrate , prepared under high vacuum conditions.

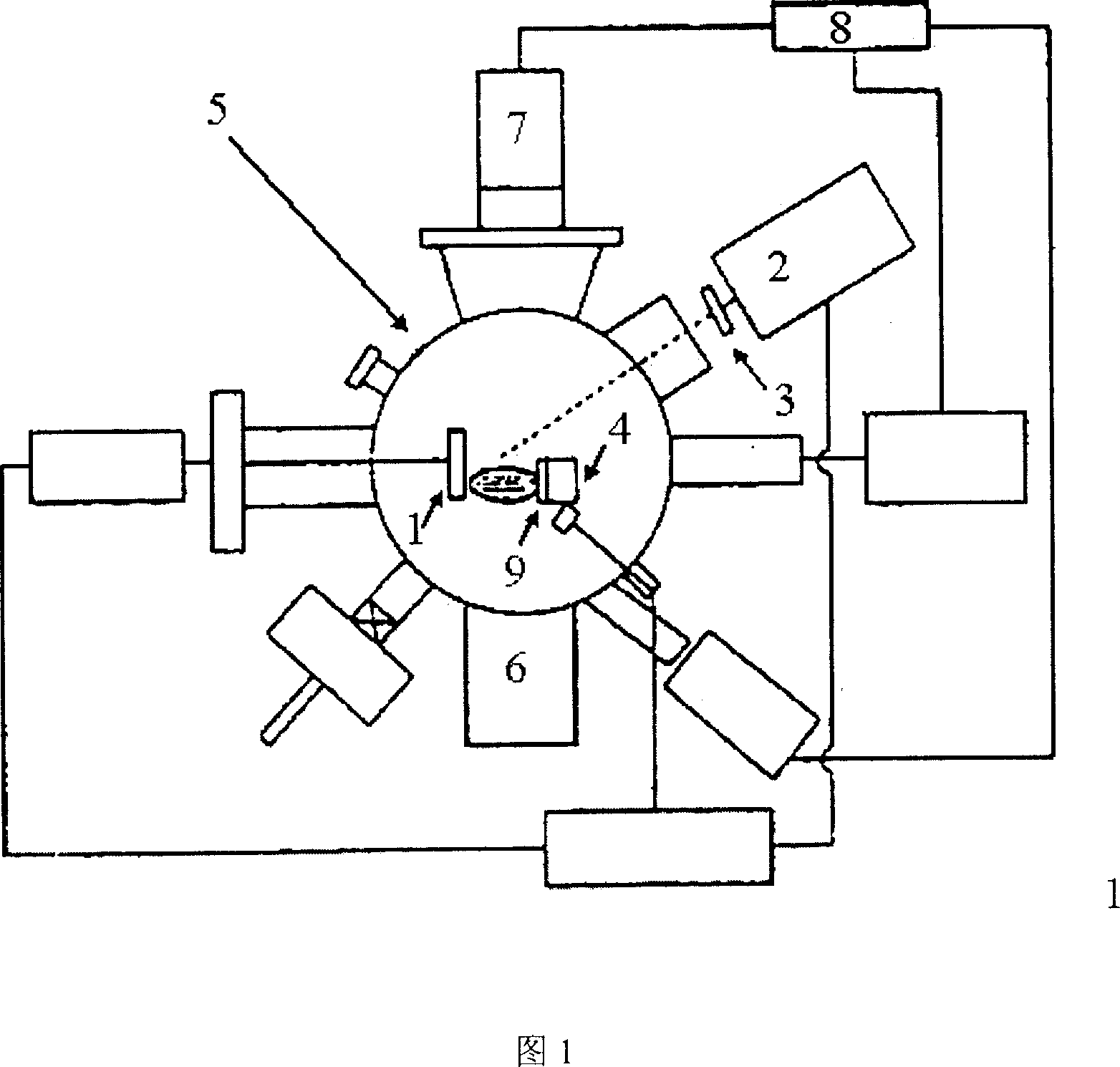

[0023] The structure diagram of the laser molecular beam epitaxy system (L-MBE) used to prepare magnesium oxide nano-films with ordered surface periodic structure according to the present invention is shown in FIG. 1 .

[0024] Specifically, the steps of the preparation method of the present invention are:

[0025] (1) Selection of magnesia ceramic target: high-purity magnesia polycrystalline ceramic target (above 99.9%), Φ50mm×5mm;

[0026] (2) Selection of substrate material: select a single crystal strontium titanate (001) substrate, and place the substrate on the substrate box 9;

[0027] (3) Place the magnesia ceramic target on the target platform 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com