a tio 2 Preparation method and application of @yeast

A yeast and dry yeast technology, applied in the fields of nanomaterials and environmental science, can solve the problems of damaging the yeast surface structure, difficult to achieve precise regulation, unable to obtain monodispersity, quantum dots, and crystal form controllable, etc. Catalytic properties, improve photocatalytic efficiency, enhance the effect of quantum effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Wash the yeast three times with distilled water and ethanol, dissolve in 30mL distilled water, stir until evenly dispersed; centrifuge and separate the obtained yeast solution, wash the obtained yeast three times with distilled water and absolute ethanol, and obtain the product Dry it in an air blast drying oven at 80°C, and cool it at room temperature to obtain yeast for measuring SEM, EDS and UV-vis.

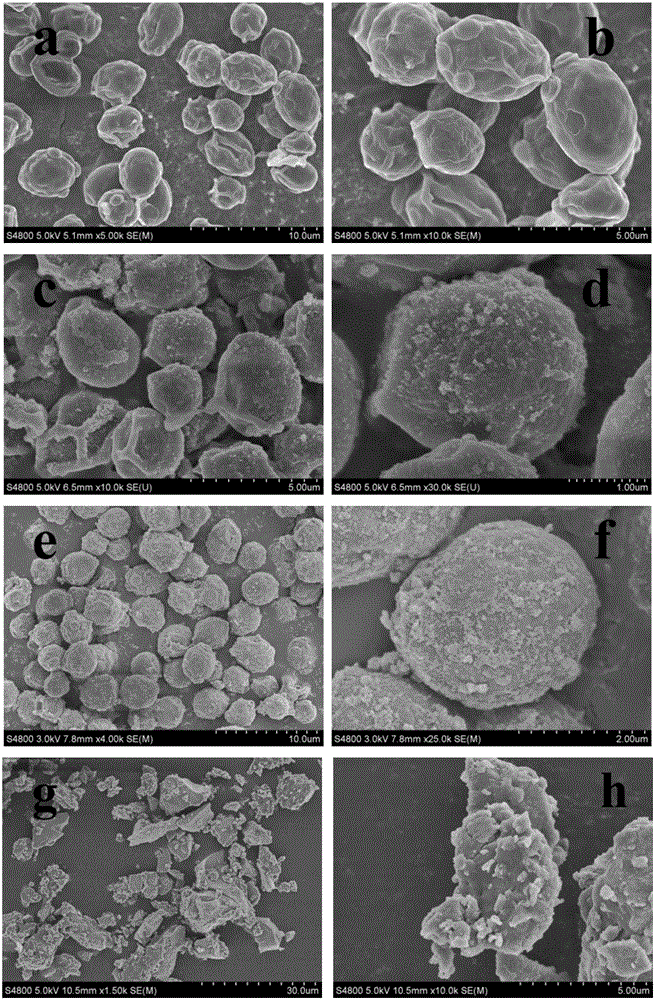

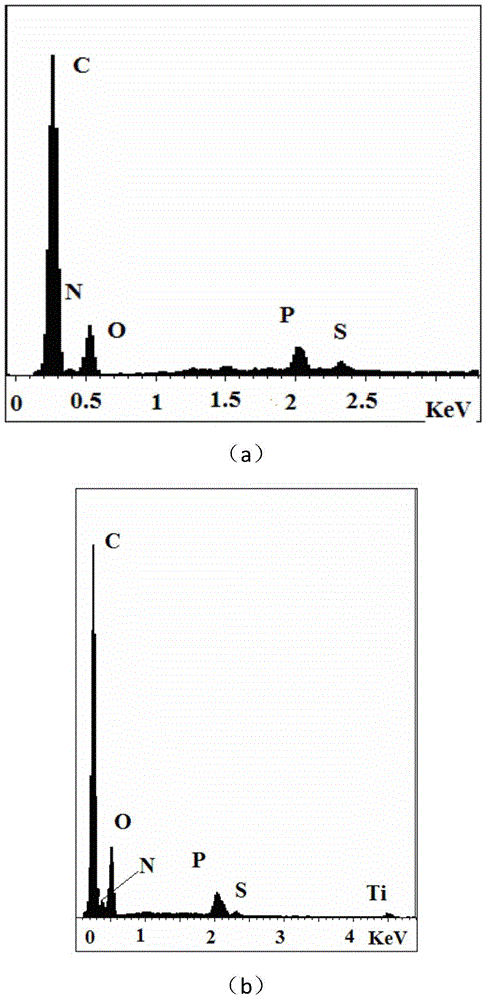

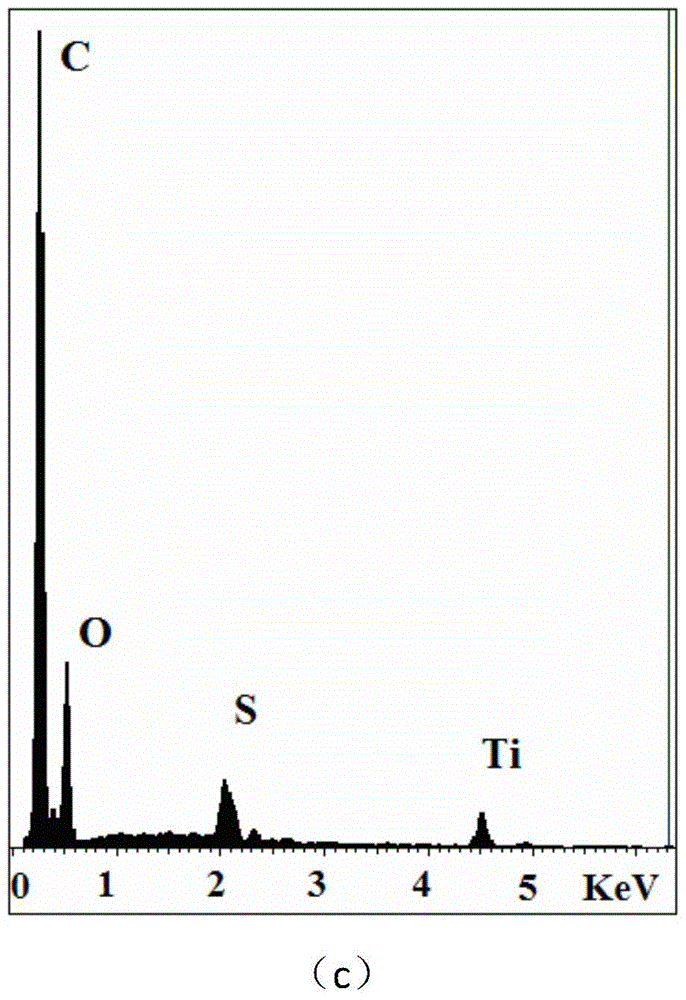

[0037] figure 1 (a), (b) are SEM images of yeast, figure 2 (a) is the EDS spectrum, image 3 (a) is the XRD pattern. From the above spectrum, it can be seen that yeast has a unique ellipsoid appearance, the main constituent elements of the cell wall are C, H (not shown), O, N, P, and S, and the main characteristic peak is the steamed bread peak at θ=20°.

Embodiment 2

[0039] Dilute titanium tetrachloride to 0.1mol / L, adjust the pH of the system to 4-6 with 4mol / L NaOH, continue to stir the mixed solution and transfer it to the reactor (filling rate is 70%-80%), and control the temperature The thermal hydrolysis reaction was carried out at 120° C., and the time was controlled at 3 hours.

[0040] The obtained solution is centrifuged and separated, and the obtained TiO 2 After washing 3 times, the obtained product was dried in a blast drying oven at 80°C, and cooled at room temperature to obtain TiO 2 .

[0041] image 3 (d) for the TiO prepared here 2 XRD spectrum, Figure 4 (a) is the UV-vis spectrum.

Embodiment 3

[0043] Wash the yeast three times with distilled water and ethanol, dissolve in 30mL distilled water, and stir until evenly dispersed;

[0044] Dilute titanium tetrachloride to 0.1mol / L, adjust the pH of the system to 4-6 with 4mol / L NaOH, control the ratio of yeast and titanium tetrachloride to 1:0.5 (g:mmol), and mix yeast and tetrachloride Titanium chloride is thoroughly mixed.

[0045] Continue to stir the mixed solution and then transfer it to the reactor (the filling rate is 70%-80%), and control the temperature at 120° C. to carry out the thermal hydrolysis reaction, and the time is controlled at 3 hours.

[0046] Centrifuge and separate the obtained solution, wash the obtained catalyst three times with distilled water and absolute ethanol, dry the obtained product in a blast drying oven at 80°C, and cool it at room temperature to obtain the catalyst with a core-shell structure. catalyst.

[0047] figure 1 (c), (d) for this TiO 2 SEM image of @yeast, figure 2 (b) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com