Non-halogen polymer-type additive resisting smelting-dropping and combustion, and its preparing process and usage

A technology of additives and polymers, applied in the direction of fire-resistant coatings, etc., can solve the problems of poor droplet resistance and cannot meet the requirements of droplet resistance and flame retardancy at the same time, and achieve good char formation, good application prospects, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

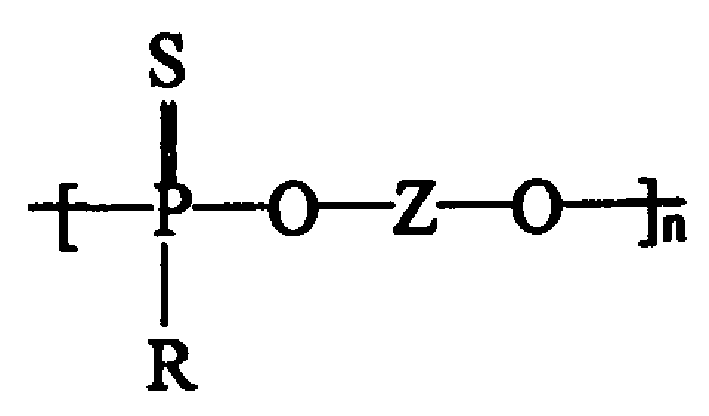

[0022] This embodiment is the preparation of polythiophenylphosphonic acid bis-p-hydroxyphenyl sulfone ester, and its reaction formula is:

[0023] Add 1 mol of thiophenylphosphonic acid dichloride, 1 mol of bisphenol S and 0.08 mol of calcium chloride into a 500 ml multi-neck flask equipped with a stirring device and nitrogen inlet and outlet, then feed nitrogen and gradually heat up while stirring Heat it to 250°C, let it melt and react for 3 hours; after the reaction is finished and cooled, add chloroform until the reactant is completely dissolved, then pour it into methanol whose volume is 5 times or more than that of the reactant solution to precipitate, and precipitate a white powdery product. The white powdery product is suction-filtered from the co-precipitant methanol, and then dried. The drying can be natural air drying or drying, preferably vacuum drying. The yield of this example is 99%, and the melting temperature of the product is 180°C.

Embodiment 2

[0025] This embodiment is the preparation of 2.2-bis-p-hydroxyphenylpropane polythiophenylphosphonate, and its reaction formula is:

[0026] Put 1 mol of thiophenylphosphonic acid dichloride, 1 mol of bisphenol A and 0.05 mol of calcium chloride in a 500 ml multi-neck bottle equipped with a stirring device and nitrogen inlet and outlet, then feed nitrogen and gradually heat under stirring Raise the temperature to 200°C, let it melt and react for 5 hours, then increase the temperature to 250°C and react for 3 hours; after the reaction is finished and cooled, add benzyl alcohol until the reactant is completely dissolved, and then pour in a volume that is 5 times or more than the volume of the reactant solution Precipitate in absolute ethanol to precipitate a white powdery product; filter the white powdery product from the co-precipitant absolute ethanol, and then dry it. The yield is 90%, and the melting temperature of the product is 140°C.

Embodiment 3

[0028] This embodiment is the preparation of polythiophenylphosphonic acid bis-p-hydroxyphenyl sulfone ester, and its reaction formula is:

[0029] In a 500ml multi-neck bottle equipped with a stirring device and a nitrogen inlet and outlet, first add 0.5mol bisphenol S and 0.03mol aluminum chloride, then feed nitrogen and gradually heat up to 230°C under stirring to melt it , then add 0.55mol thiophenylphosphonic acid dichloride dropwise, and control the dropping time for 1 hour. After the dropwise addition is completed, react for 3 hours; Precipitate in methanol with a volume of 5 times or more of the product solution, and precipitate a white powdery product; filter the white powdery product from the co-precipitant methanol, and then dry it. The yield is 95%, and the melting temperature of the product is 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com