Extraction of panax notoginseng leaf saponine

An extraction method and a technology of notoginseng saponins, which are applied in the field of extraction and separation of effective components of traditional Chinese medicine, can solve problems such as product loss and yield decline, and achieve the effects of low production cost, increased yield, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The synthesis of ADS-3 resin: oil phase system preparation: take by weighing reaction monomer divinylbenzene 80g, styrene 20g, with 150% toluene and liquid wax (1: 1) as porogen, 1% BPO is initiator, Mix evenly; configuration of the water phase system: take 5 times the water of the oil phase, add 1% gelatin or polyvinyl alcohol to form the water phase system. The experimental process is as follows:

[0024] Step 1: Preparation of St-DVB white balls Heat the water phase to 45°C, dissolve the dispersant completely under stirring, add 6 drops of methylene blue dropwise, and stop stirring. Put the oil phase in the water phase, adjust the stirring (250 rpm) to a suitable particle size, then raise the temperature to 78°C-80°C at a speed of 1°C / 2min, react for 2 hours, and raise the temperature to 85°C at the same heating rate to react After 3 hours, heat up to 90-95°C and cook the balls for 6 hours. Take out the ball, wash with hot water, dry in the air, extract with petrol...

Embodiment 2

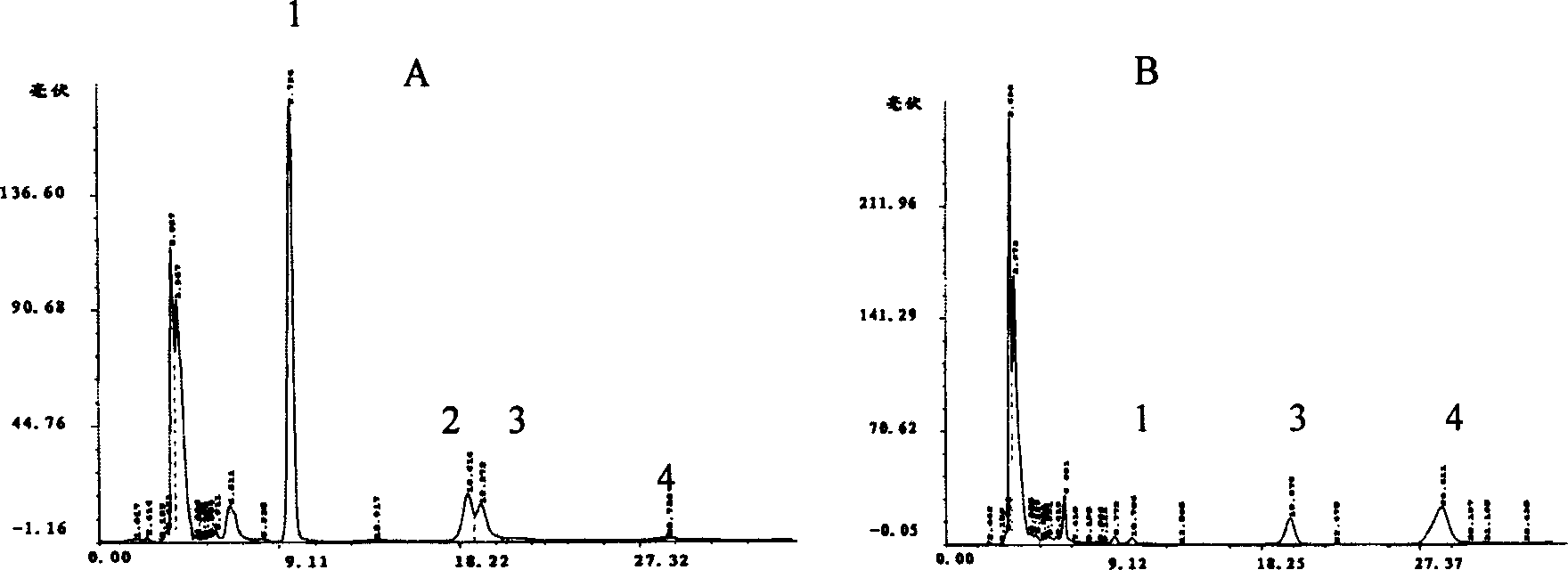

[0032] Grind 20 grams of Panax notoginseng leaves, extract with hot water at 40°C, concentrate the extract to 100ml, and filter the clarified aqueous solution. Pass the obtained aqueous solution into a resin column equipped with ADS-3 resin (column diameter 15 mm, 50 ml of resin is installed), wash with 100 ml of water, and desorb with 200 ml of 70% ethanol. The flow rate of adsorption, washing and desorption is 1 times of bed volume / hour. The desorbed liquid was concentrated under reduced pressure, dried in vacuum, and pulverized to obtain 1.79 g of a white powdery notoginseng saponin extract, with a yield of 8.94%. Through Waters484 type high performance liquid chromatograph chromatographic analysis, the result is: the product purity is Rg 1 6.27%, Rb 1 32.0% and R 1 15.6%. According to UV analysis, the total saponin content is 91.4%.

Embodiment 3

[0034] Grind 20 grams of Panax notoginseng leaves, extract at room temperature, concentrate to 120ml, and filter the clear aqueous solution. Pass the obtained aqueous solution into a resin column equipped with ADS-3 resin (column diameter 15 mm, 80 ml of resin is installed), wash with 160 ml of water, and desorb with 300 ml of 50% ethanol. The flow rate of adsorption, washing and desorption is 0.5 times bed volume / hour. The desorbed liquid was concentrated under reduced pressure, dried in vacuum and pulverized to obtain 1.72 g of a white powdery notoginseng saponin extract with a yield of 8.71%. Through the chromatographic analysis of Waters484 type high performance liquid chromatography, the result is: the product purity is ginsenoside Rg 1 6.89%, Rb 1 32.8% and R 1 16.1%. According to UV analysis, the total saponin content is 94.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com