Packaging bag and its making method

A packaging bag and film layer technology, which is applied in the field of packaging supplies, can solve problems such as difficulty, high manufacturing cost, and impracticality, and achieve the effect of scientific materials, scientific selection, and ideal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

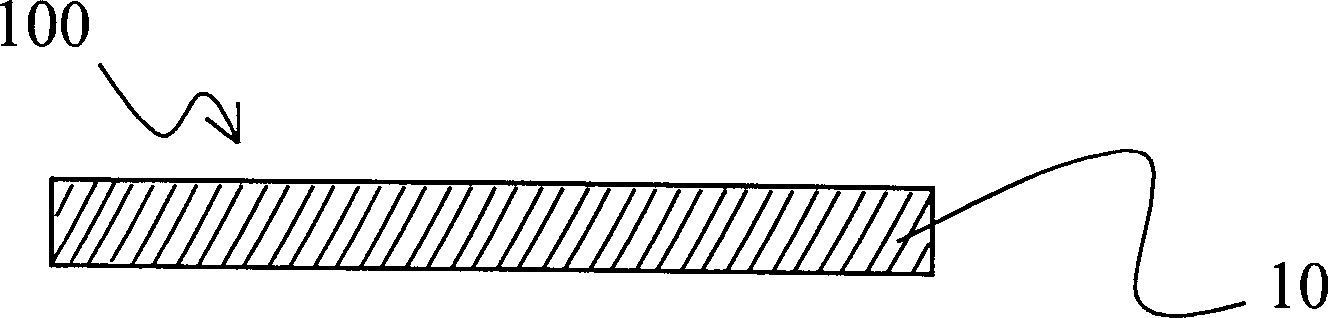

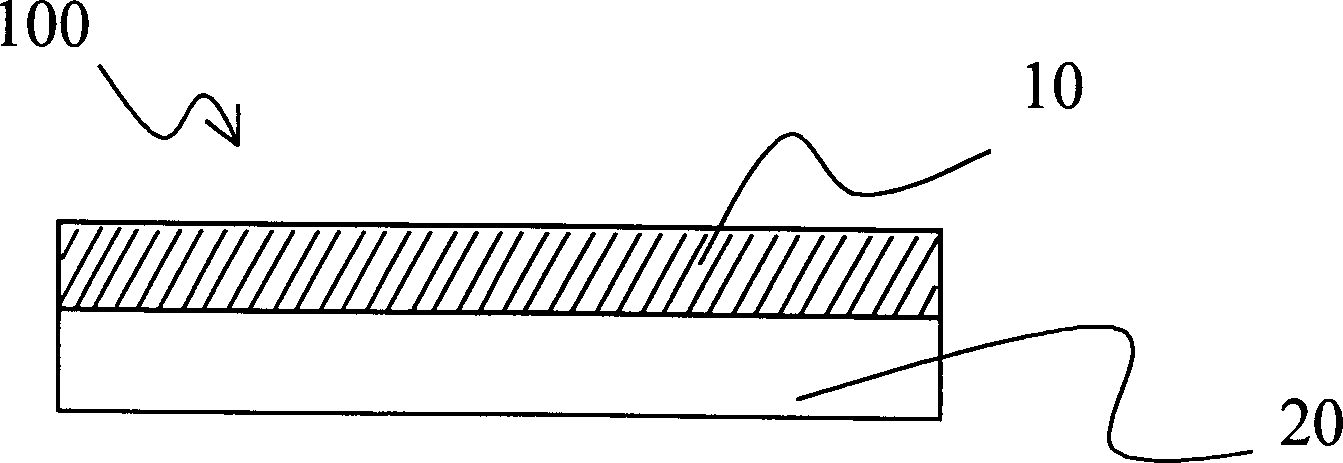

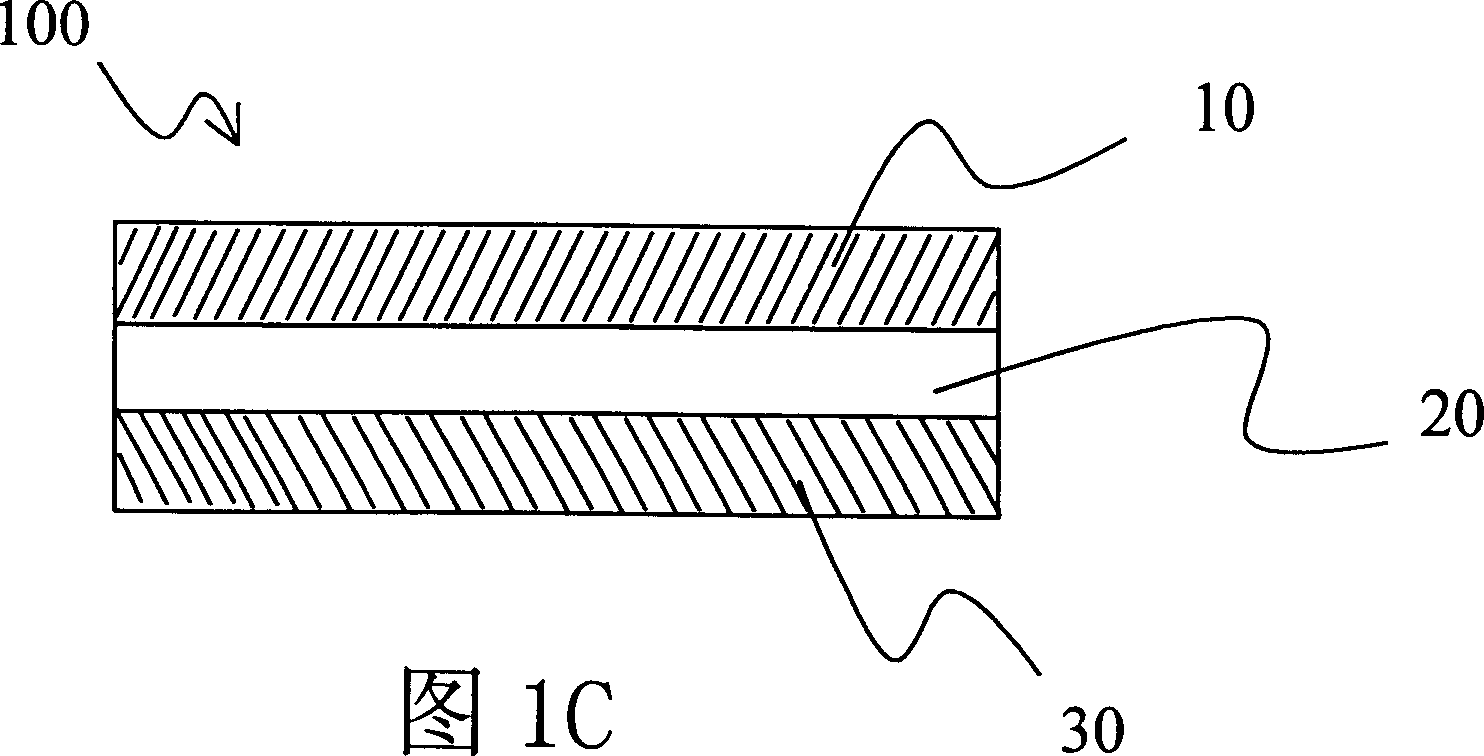

[0037] refer to Figure 1A As shown, the present invention provides a film layer structure 100 which is a layer of heat-sealable material capable of heat melting, and the film layer 10 shown in it is selected from acrylic, polyester, polyethylene, PE), polypropylene (polypropylene, PP), polythiamine (polyamide, nylon), polyethylene and polypropylene copolymer, ethylene and styrene copolymer (ethylene-styrenecopolymer, ES), cyclic olefin copolymer Polymer (cyclo olefin), polyethylene terephthalate (polyethylene terephthalate, PET), polyvinyl alcohol (polyvinyl alcohol, PVA), ethylene-vinylacetate (EVA), or made of (SurlynTm (Dupontionomer Ionic polymer compound trade name), polyethylene glycol terephthalate (polyethylene naphthalate, PEN), polyether ketone (poly ether ketone, PEEK), polycarbonate (polycarbonate, PC), polysulfone (polysulfone ), polyimide (PI), polyacrylonitrile (PAN), styrene and acrylonitrile copolymer (styrene acrylonitrile, SAN), polyurethane (polyurethane, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com