Niobium or tantalum powder and method for production thereof, and solid electrolytic capacitor

A powder and volume technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve problems such as increased number of processes, reduced adhesion strength, and influence on capacitor characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

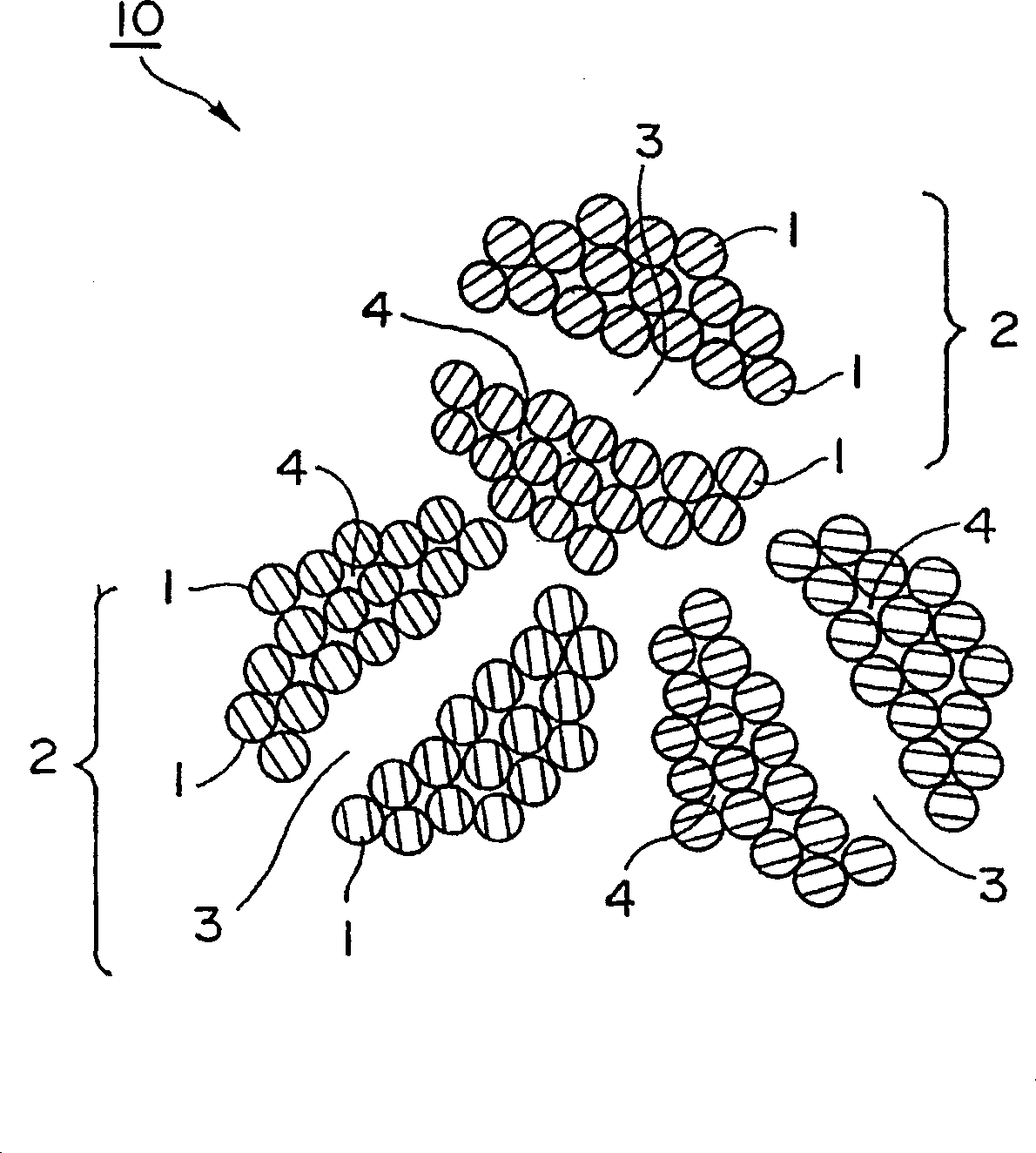

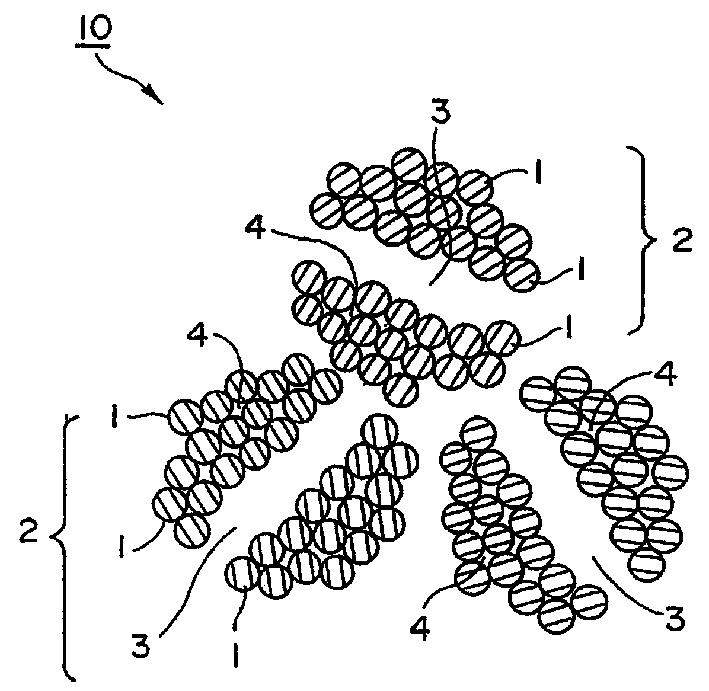

Image

Examples

Embodiment 1

[0056] In a 50 L reaction vessel, 15 g each of potassium fluoride and potassium chloride for diluting the salt was added, and the temperature was raised to 850° C. to prepare a molten solution. To this melt, 200 g of potassium tantalum fluoride was added at a time, and after 1 minute, 58 g of dissolved sodium was added and reacted for 2 minutes. This operation was repeated 30 times.

[0057] After the reduction reaction was completed, it was cooled, and the obtained agglomerates were pulverized and washed with a weakly acidic aqueous solution to obtain tantalum particles. Further, it is refined with a washing liquid containing hydrofluoric acid and hydrogen peroxide. The yield of the reduced particles of tantalum was 1.6 kg.

[0058] The tantalum particles thus obtained have the following characteristics.

[0059] BET specific surface area 1.8m 2 / g

[0060] The average particle size of the primary particles is 200nm

[0061] Apparent average particle size 10μm (D 50 %)...

Embodiment 2

[0068] In the same manner as in Example 1, reduced tantalum particles were obtained. Then, 100 g of the reduced tantalum particles were pulverized with a microball mill in absolute ethanol. Thereafter, 3 g of magnesium hydride particles with a diameter of 7 μm and 20 mg of ammonium phosphate hexafluoride powder were added, mixed, and dried in a vacuum dryer at 50° C. to remove the alcohol component to obtain a solid. The amount of magnesium hydride added was about 20% by volume relative to the reduced particles. This solid was heated at 800° C. for 1 hour in a vacuum heating furnace, and further heat-treated at 1200° C. for 0.5 hour. Through such an operation, oxygen (deoxidation) on the surface of the tantalum is removed and thermally condensed at the same time.

[0069] Then, the aggregated particles were pulverized in an inert atmosphere, and the particle size was adjusted so that the average particle diameter was about 100 μm. Further, it is washed with a mixed acid of ...

Embodiment 3

[0073] In the same manner as in Example 1, reduced tantalum particles were obtained. Then, 2 g of fibrous magnesium metal (about 8 μm in diameter and 100 to 300 μm in length) was added to 100 g of the reduced tantalum particles, and after mixing well, phosphoric acid aqueous solution was added a little at a time while vibrating to obtain a lump. of solids. The amount of magnesium metal added was 14% by volume relative to the reduced particles. The amount of water required for agglomeration was 22 ml, and the content of phosphoric acid was 150 ppm with respect to the tantalum particles.

[0074] The solid was heated to 800° C. in a vacuum heating furnace, kept for 1 hour, and then heated to 1150° C. for 0.5 hour heat treatment. Thereafter, argon gas is passed into the furnace to oxidize and stabilize the tantalum metal.

[0075] Then, take out the solid matter from the furnace, coarsely pulverize it with a roller crusher in an argon flow, and further pulverize it with a pin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com