Technique for preparing silicon nitride powders with high alpha phase by using plasma chemical vapor phase process

A phase silicon nitride powder, plasma technology, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., can solve the problems of high C content in the product, doping, complicated process control, etc., to achieve uniform particle size distribution, high The effect of high α-phase content and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

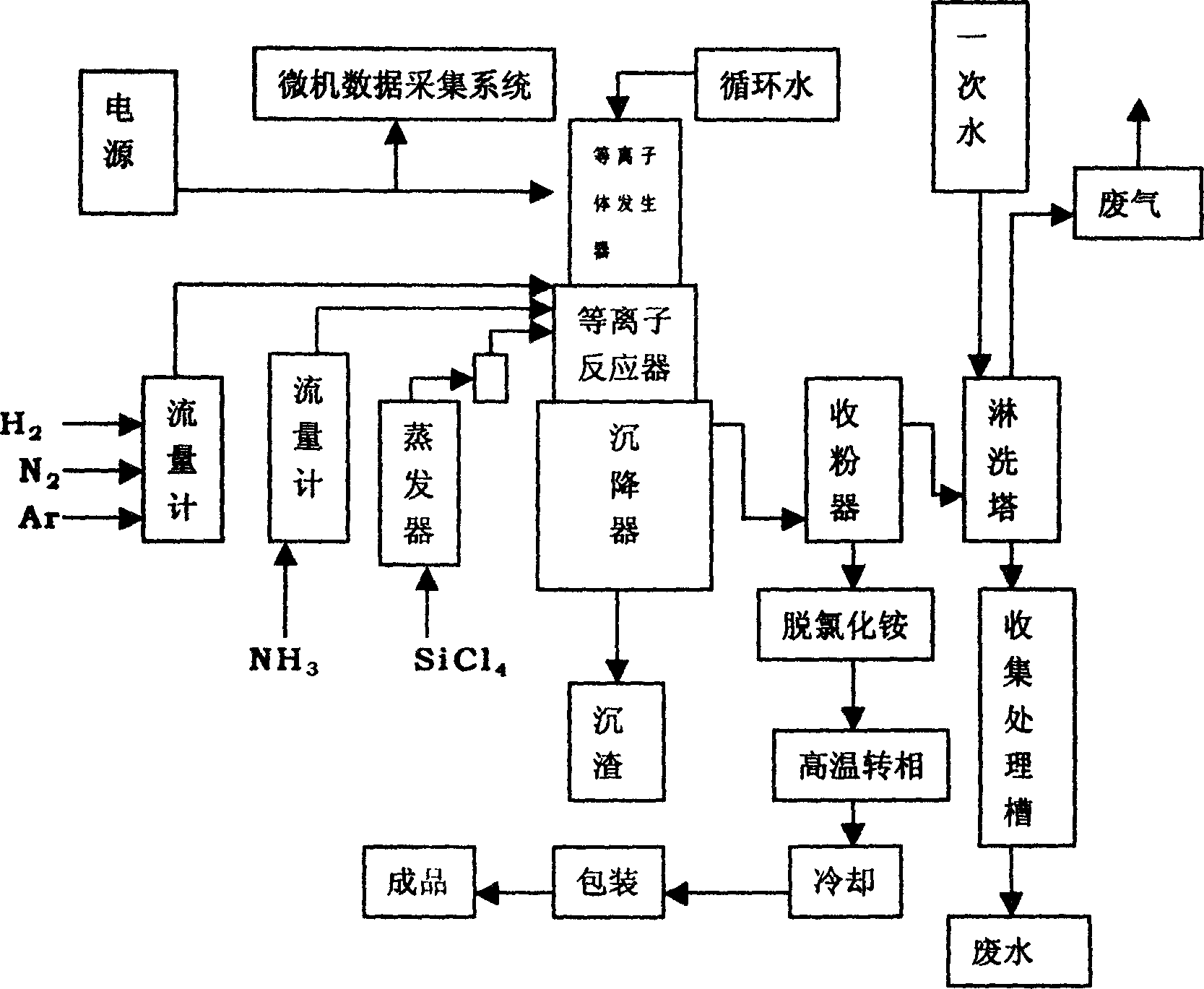

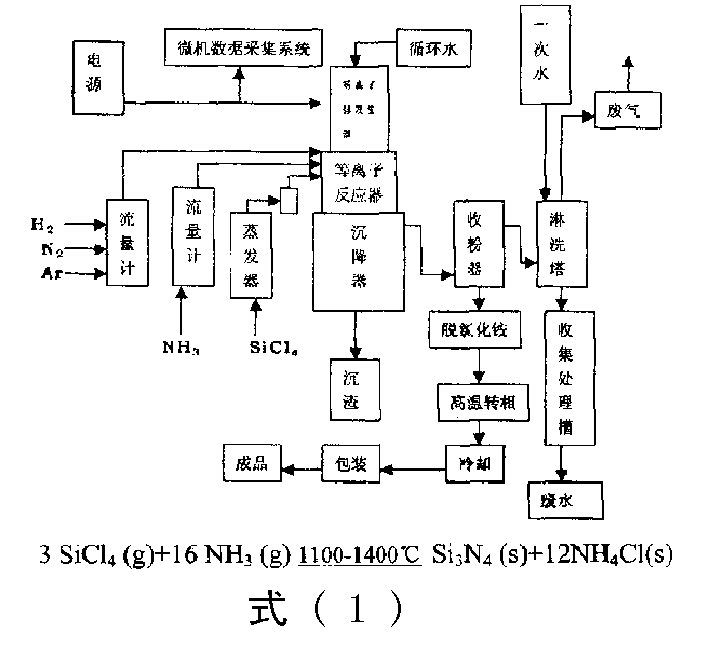

Method used

Image

Examples

Embodiment 1

[0021] First, the plasma working gas N is introduced into the plasma generator 2 -H 2 -Ar, press N 2 9m 3 / h; H 2 27m 3 / h; The flow rate is continuously injected, and 30 liters / min of Ar is injected, the plasma power supply is started, and a plasma arc is generated in the plasma generator, (the Ar gas is turned off after the arc starts normally). The gas after the arc is heated to a high temperature of 4800°C and enters the reactor to decompose rapidly, keeping SiCl 4 and NH 3 The ratio is 1:8 (injection liquid weight ratio per unit time) for continuous injection, and the reaction temperature in the plasma reactor is kept at 1250°C. Si 3 N 4 Rapid decomposition in a plasma reactor and generation of solid Si using free-settling and quenching conditions 3 N 4 micronized powder,

[0022] Generated Si 3 N 4 After crystallization and growth in a very short time (millisecond level), after cooling, the gas-solid separation is achieved through the bag powder collec...

Embodiment 2

[0027] First, the plasma working gas N is introduced into the plasma generator 2 -H 2 -Ar, press N 2 13m 3 / h; H 2 32m 3 / h; The flow rate is continuously injected, and 30 liters / min of Ar is injected, the plasma power supply is started, and a plasma arc is generated in the plasma generator, (the Ar gas is turned off after the arc starts normally). After the arc gas is heated to a high temperature of 5200°C, it enters the reactor and decomposes rapidly, keeping SiCl 4 and NH 3 The ratio is 1:5 (injection liquid weight ratio per unit time) for continuous injection, and the reaction temperature in the plasma reactor is kept at 1100°C. Rapid decomposition in a plasma reactor and generation of solid Si using free-settling and quenching conditions 3 N 4 micronized powder,

[0028] Generated Si 3 N 4 After crystallization and growth in a very short time (millisecond level), after cooling, the gas-solid separation is achieved through the bag powder collector to obtai...

Embodiment 3

[0032] First, the plasma working gas N is introduced into the plasma generator 2 -H 2 -Ar, press N 2 11m 3 / h; H 2 30m 3 / h; The flow rate is continuously injected, and 30 liters / min of Ar is injected, the plasma power supply is started, and a plasma arc is generated in the plasma generator, (the Ar gas is turned off after the arc starts normally). The gas after the arc is heated to a high temperature of 5000°C and enters the reactor to decompose rapidly, keeping SiCl 4 and NH 3 The ratio is 1:10 (injection liquid weight ratio per unit time) for continuous injection, and the reaction temperature in the plasma reactor is kept at 1400°C. Rapid decomposition in a plasma reactor and generation of solid Si using free-settling and quenching conditions 3 N 4 micronized powder,

[0033] Generated Si 3 N 4 After crystallization and growth in a very short time (millisecond level), after cooling, the gas-solid separation is achieved through the bag powder collector to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com