Method for modulating multipath light simultaneously using waveguide resonance mode and modulator

A guided wave resonance and modulator technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of integrating multiple M-Zs, integration difficulties, multi-channel integration M-Z modulators, etc., to achieve convenient material processing and low cost Low cost and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

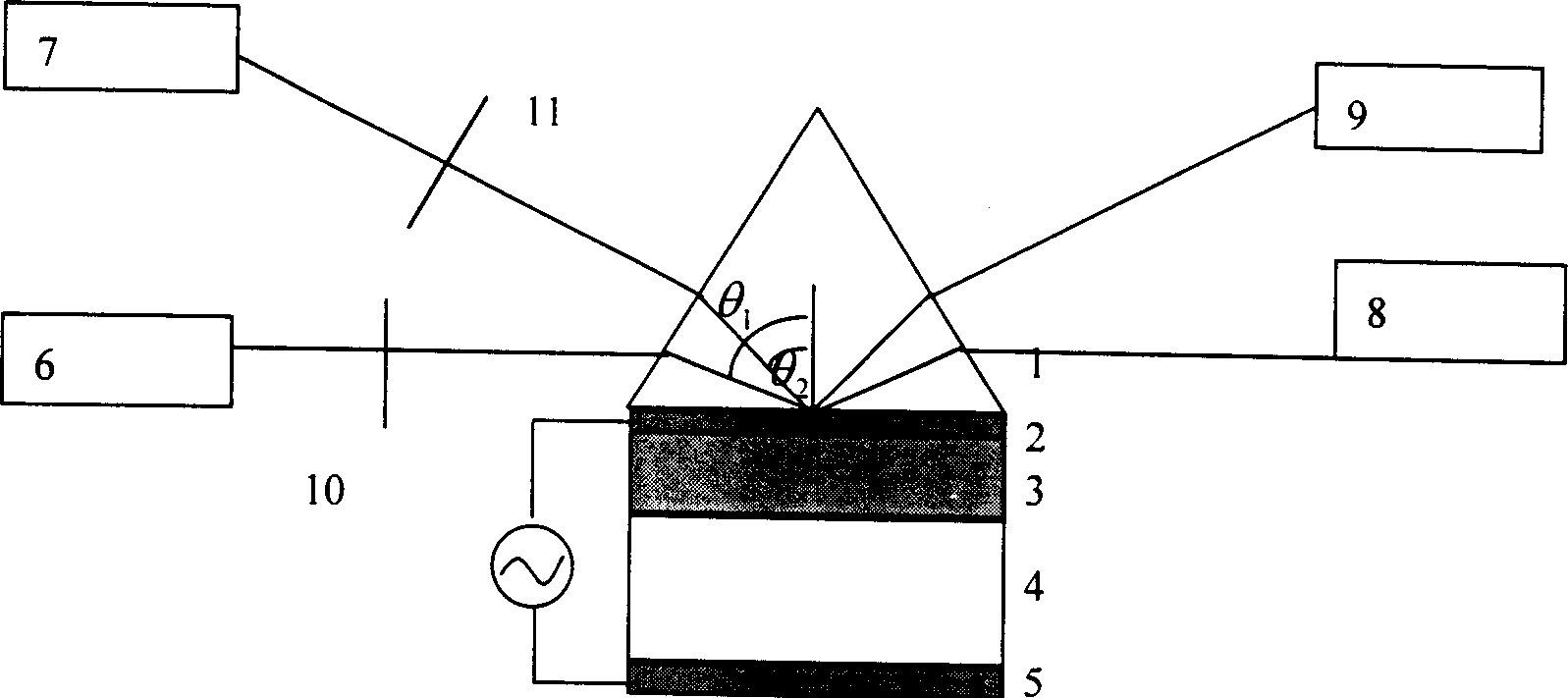

[0024] Simultaneous modulation of two channels of light is achieved using different guided wave resonance modes (TM1 and TM2) of the same wavelength (832nm):

[0025] Step 1: The material of the prism 1 is an equilateral triangular prism with high refractive index (ZF6, n=1.7355). The material of the upper metal film 2 is silver (ε=-30.0+i1.5), which is plated on the bottom surface of the prism 1 by sputtering method, with a thickness of 45.0 nm. The electro-optic polymer film 3 is made of cross-linked organic material with a refractive index of 1.680 and a thickness of 3.0 μm. Then, near the glass transition temperature (160°C) of the electro-optic polymer 3 material, a very high electric field (3800V) is applied on the metal needle tip vertically above the polymer surface to discharge the air. Then the polar molecules inside the polymer will be neatly arranged under the action of the electric field. Then keep the electric field, and slowly lower to room temperature. At th...

Embodiment 2

[0028] Simultaneous modulation of two channels of light using the same guided wave resonance mode (TM1) at different wavelengths (832nm and 980nm):

[0029] Step 1: The material of the prism 1 is an equilateral triangular prism with high refractive index (ZF7, n=1.7837). The material of the upper metal film 2 is silver (ε=-30.0+i1.5), which is plated on the bottom surface of the prism 1 by sputtering method, with a thickness of 55.0 nm. The electro-optic polymer film 3 is made of cross-linked organic material with a refractive index of 1.680 and a thickness of 3.5 μm. Then, near the glass transition temperature (160°C) of the electro-optic polymer 3 material, a very high electric field (4000V) is applied on the metal needle tip vertically above the polymer surface to discharge the air. Then the polar molecules inside the polymer will be neatly arranged under the action of the electric field. Then keep the electric field, and slowly lower to room temperature. At this time, t...

Embodiment 3

[0032] Using different guided wave resonance modes of different wavelengths - TM1 at 832nm and TE2 at 980nm to achieve simultaneous modulation of two channels of light:

[0033] Step 1: The material of the prism 1 is an equilateral triangular prism with high refractive index (n=1.900). The material of the upper metal film 2 is silver (ε=-30.0+i1.5), which is plated on the bottom surface of the prism 1 by sputtering method, with a thickness of 60.0 nm. The electro-optic polymer film 3 is made of cross-linked organic material with a refractive index of 1.680 and a thickness of 4.0 μm. Then, near the glass transition temperature (160°C) of the electro-optic polymer 3 material, a very high electric field (4300V) is applied on the metal needle tip vertically above the polymer surface to discharge the air. Then the polar molecules inside the polymer will be neatly arranged under the action of the electric field. Then keep the electric field, and slowly lower to room temperature. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electro-optic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com