Composite quantum point device and a process for making it

A quantum dot device and quantum dot technology, applied in the field of composite quantum dot devices and preparation, can solve the problems of metamorphosis, penetration of quantum dot quality, and single function, and achieve the effects of stable performance, simplified device preparation process, and controllable application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

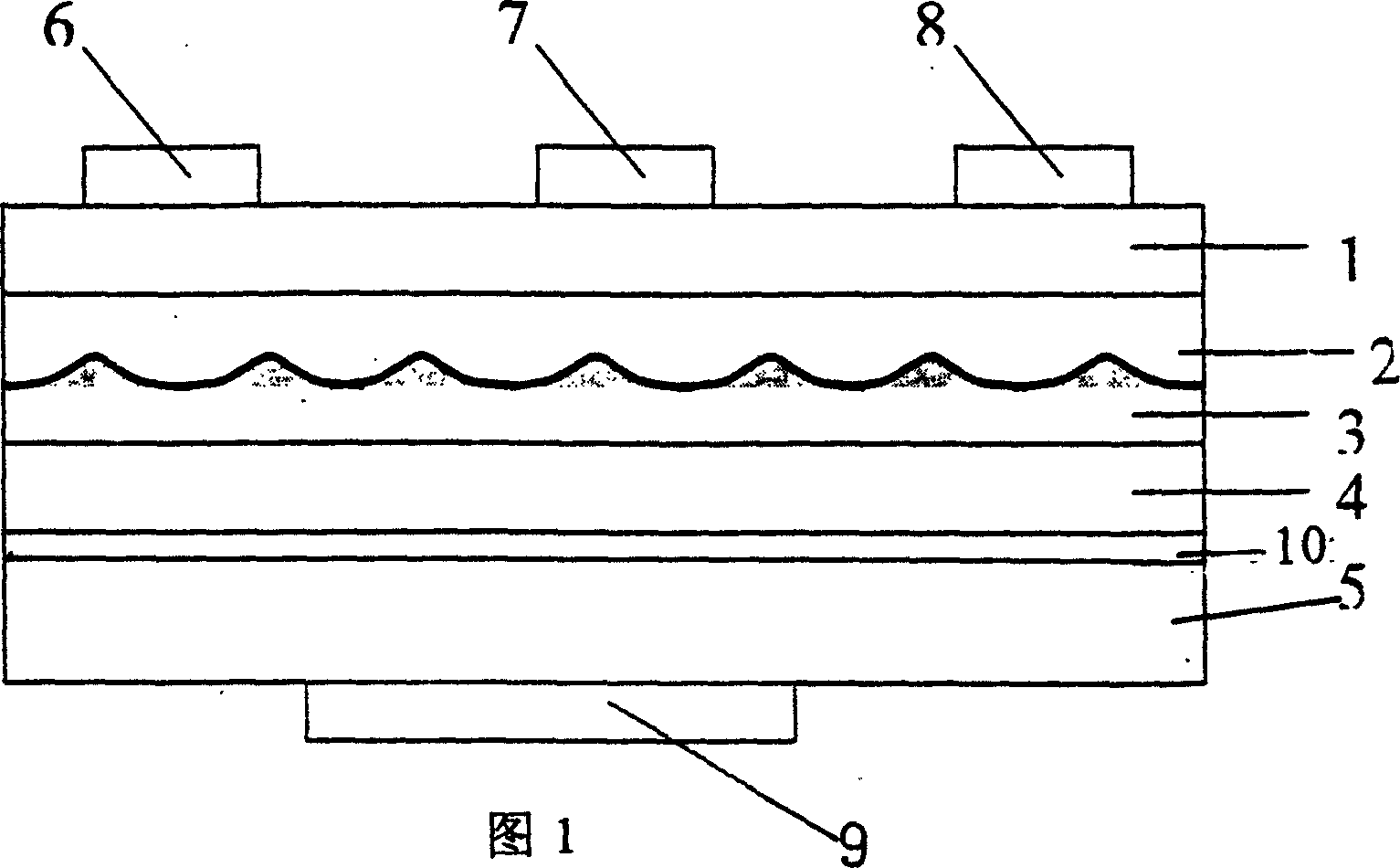

[0041] Referring to Figure 2 for the structure of the device produced in this embodiment, the structure of the device is grown by the molecular beam MBE method, and its structure will be described in detail in conjunction with the fabrication method of the device:

[0042] (a) Using Si-doped n + The (001) orientation GaAs is used as the substrate, and the device structure includes from bottom to top on the substrate: 2.0μm GaAs buffer layer, the substrate and buffer layer are 5; 70nm thick Al 0.3 Ga 0.7 As / GaAs superlattice barrier 10, where Al 0.3 Ga 0.7 As thickness is 5nm, GaAs is 2nm, a total of 10 periods; δ-Si doped layer 4, after doping carrier surface density is 3.8×10 11 cm 2 ; 4nm thick GaAs layer is the semiconductor isolation layer 3; Quantum dots are grown under the condition of substrate rotation, the amount of InAs deposited is 1.8ML, the substrate temperature for deposition is 440°C, the effective diameter of quantum dots is 12nm, and the density of quantu...

Embodiment 2

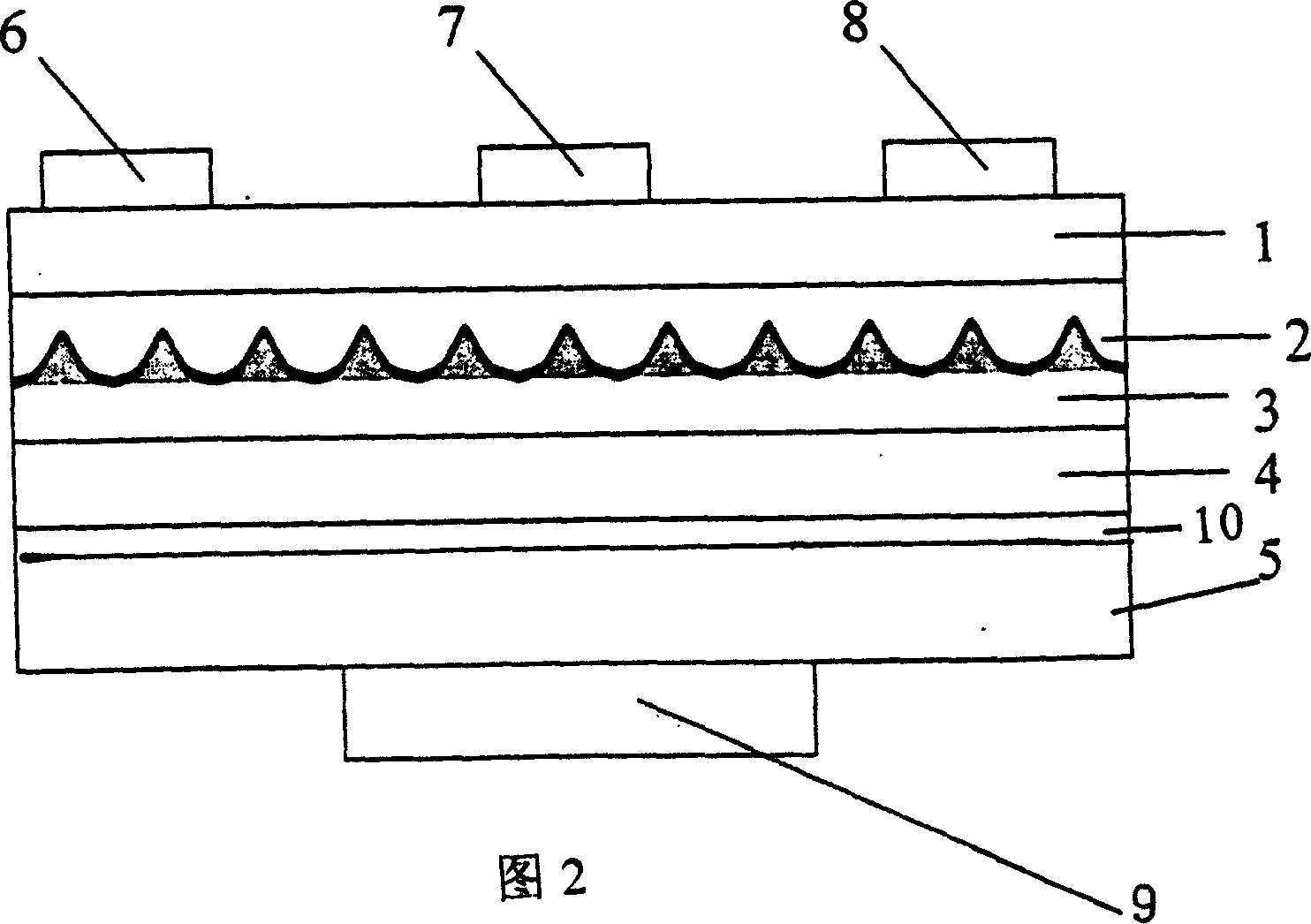

[0047] Referring to Figure 3 for the structure of the device produced in this embodiment, the structure of the device is grown by the molecular beam MBE method, and its structure is described in detail in conjunction with the fabrication method of the device:

[0048] (a) Using Si-doped n + The (001) orientation GaAs substrate, the device structure on the substrate from bottom to top includes: 1.0μm n + -GaAs buffer layer with a doping concentration of 1.0×10 18 cm -3 , the substrate and buffer layer are shown as 5 in Figure 3; the 700nm thick Al 0.3 Ga 0.7 As / GaAs superlattice barrier 10, where Al 0.3 Ga 0.7 The thickness of As is 5nm, GaAs is 2nm, a total of 100 periods; a layer of δ-Si doped layer 4, the surface density of carriers after doping is 4.8×10 11 cm -2 5nm thick GaAs semiconductor isolation layer 3; InAs quantum dot layer 2 with a thickness of 0.9 nanometers, and a 3nm thick GaAs capping layer, that is, the semiconductor capping layer 1. The quantum dots ...

Embodiment 3

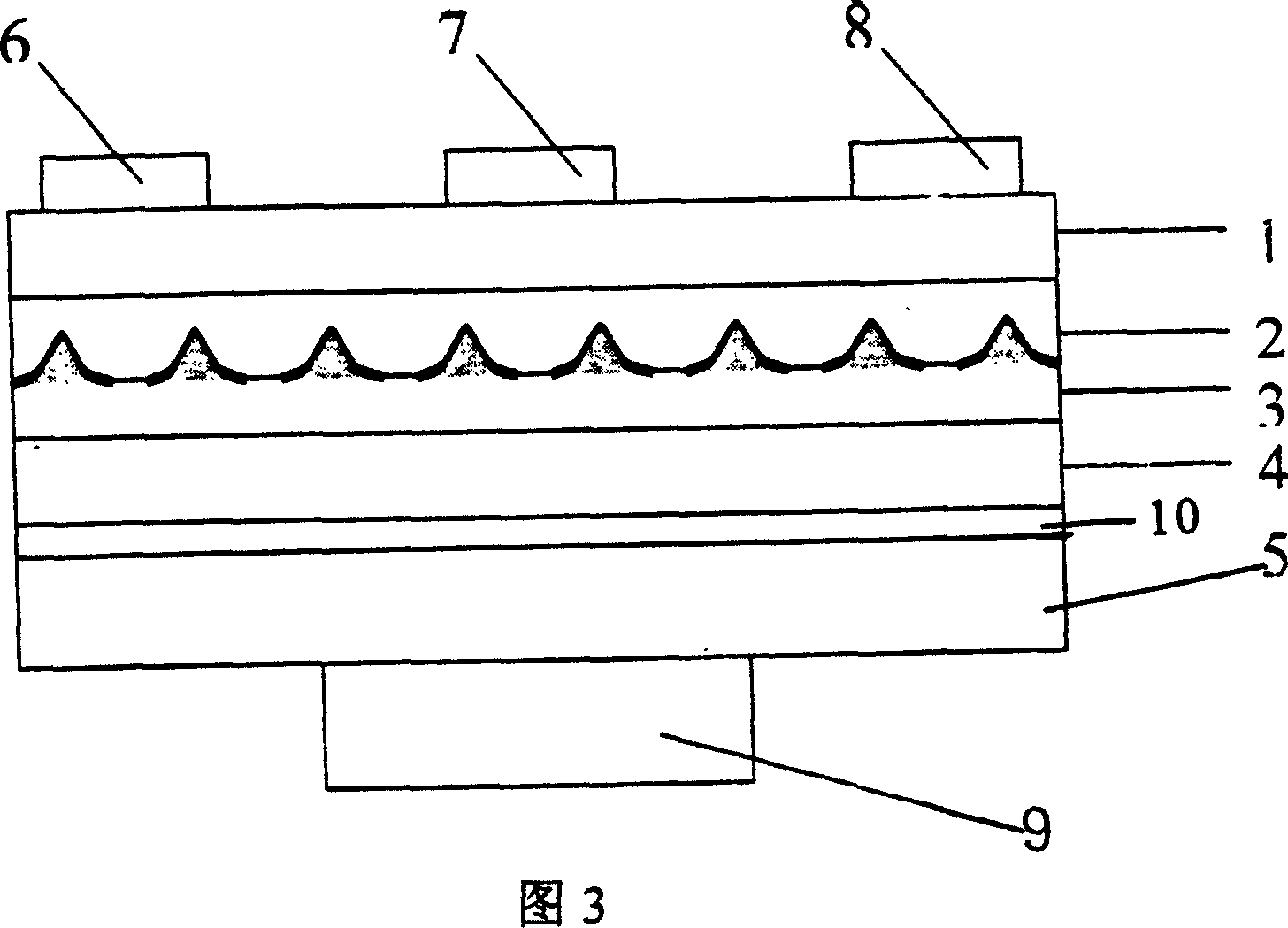

[0052] Referring to Figure 4 for the structure of the device produced in this embodiment, the structure of the device is grown by the molecular beam MBE method, and it is described in detail in conjunction with the manufacturing method of the device:

[0053] Si-doped n + The (001) orientation GaAs substrate, the device structure includes from bottom to top on the substrate: 2.0μm GaAs buffer layer; 70nm thick Al 0.3 Ga 0.7 As / GaAs superlattice barrier 10, where Al 0.3 Ga 0.7 As thickness is 5nm, GaAs is 2nm, a total of 10 periods; a layer of δ-Si doped layer 4, after doping carrier surface density is 1.4×10 11 cm -2 ; 4nm thick GaAs layer is the semiconductor isolation layer 3; Quantum dots are grown under the condition of substrate rotation, the deposition amount of InAs is 1.2ML, the substrate temperature of deposition is 400℃, the effective diameter of quantum dots is 15nm, and the density of quantum dots is 2.3×10 10 cm -2. After the device material is grown and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com