Sewage containing high concentration organics and ammonia nitrogen disposal method

An organic, high-concentration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high power consumption, poor denitrification effect, construction and operation costs of treatment facilities increase and other problems, to achieve the effect of reducing reaction time and energy consumption, and reducing the concentration of ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

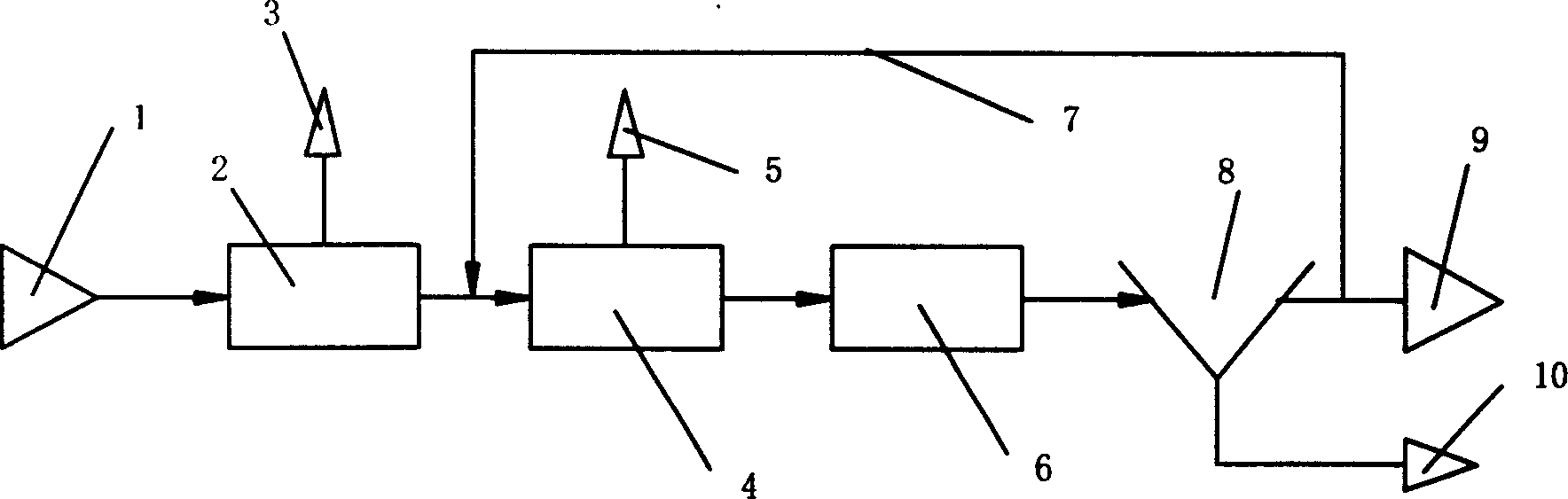

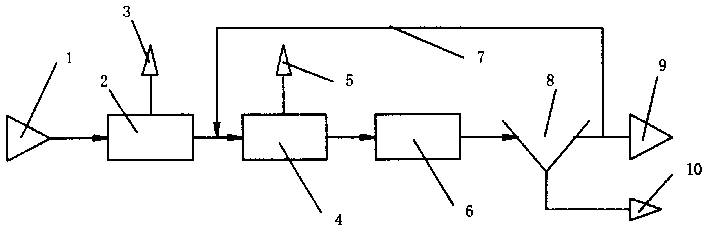

[0023] The method of the present invention is used to treat the mixed sewage discharged from the rice washing and soybean cooking process of a certain rice raw material winery, and the sewage flow rate is 350m 3 / d, the process used is as follows figure 1 shown. First, the sewage is sent to the anaerobic treatment unit A[2] for treatment. The concentration of organic matter in the influent water is 5000mg / LCODcr, the concentration of total nitrogen is 500mg / L, the hydraulic retention time is 20 hours, and the water temperature in the anaerobic unit is 33- At 37°C, the removal rate of organic matter is 80%, and the biogas obtained per cubic meter of sewage is 2.0Nm 3 ; The effluent of anaerobic treatment unit A[2] is mixed with return water [7] and then sent to anaerobic treatment unit B[4] for treatment. The hydraulic retention time is 10 hours, and the removal rate of organic matter is 70%. m sewage get biogas 0.5Nm 3 The effluent of anaerobic treatment unit B [4] is sent ...

Embodiment 2

[0025] The method of the present invention is used to treat the sewage discharged from the alcohol distillation tower of a corn raw material alcohol factory, and the sewage flow rate is 700-800m 3 / d, the process used is as follows figure 1 shown. First, the sewage from which suspended solids have been removed is sent to the anaerobic treatment unit A[2] for treatment. The concentration of organic matter in the influent water is 25000-30000mg / LCODcr, the concentration of total nitrogen is 1500mg / L, and the hydraulic retention time is 30 hours. The water temperature in the tank is 53-57°C, the removal rate of organic matter is 90%, and 13.5Nm of biogas is obtained per cubic meter of sewage 3 ; The effluent of anaerobic treatment unit A[2] is mixed with return water [7] and then sent to anaerobic treatment unit B[4] for treatment. The hydraulic retention time is 15 hours, and the water temperature in the device is 33-37°C. The removal rate is 70%, and every cubic meter of sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com