Method for coating metal materials and coated materials

A technology of metal materials and coating methods, which is applied to the metal material coating process, the device for coating liquid on the surface, coating, etc., and can solve the problems that the coating method cannot be used, the adhesion is poor, and the repair is impossible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

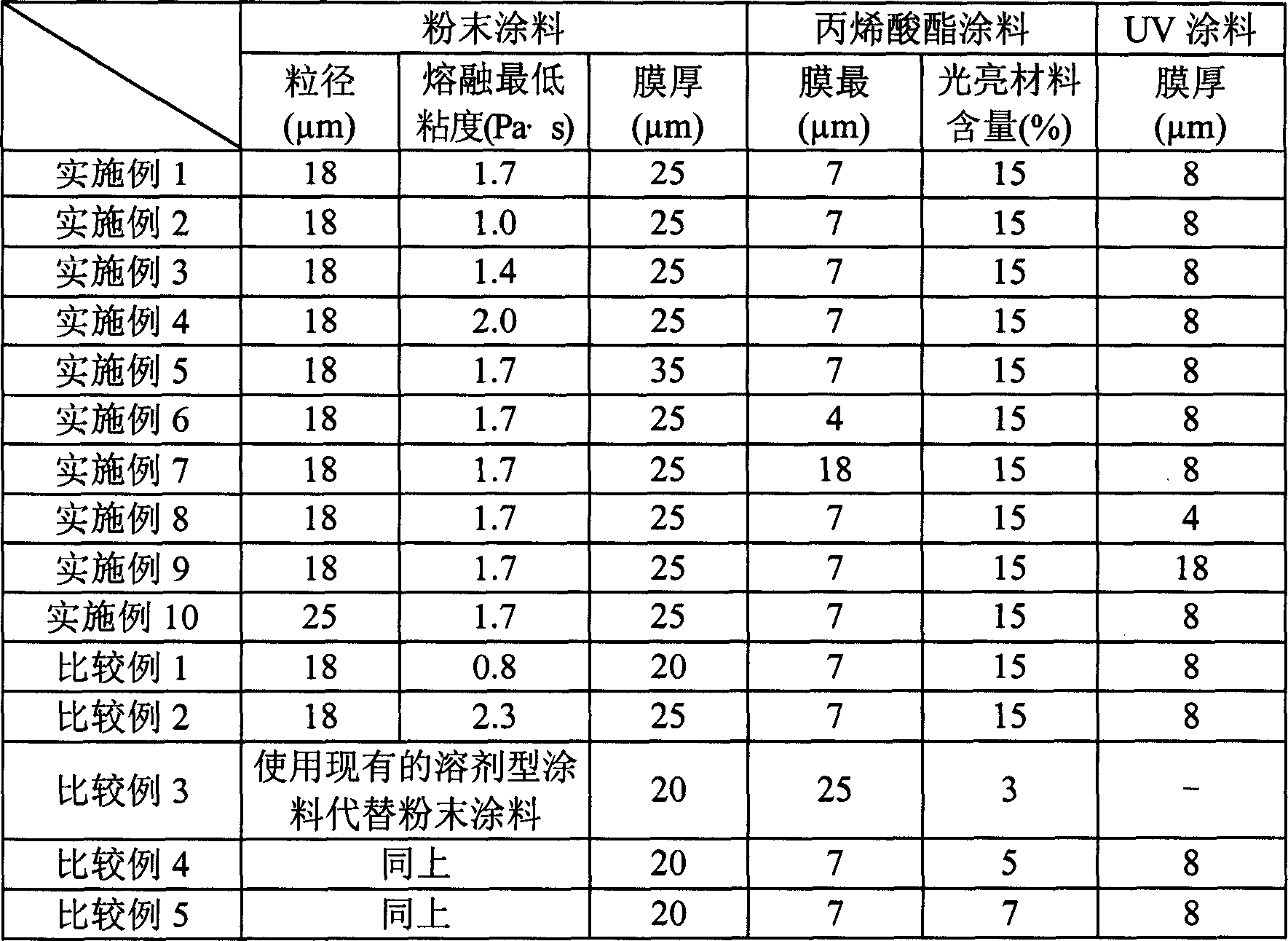

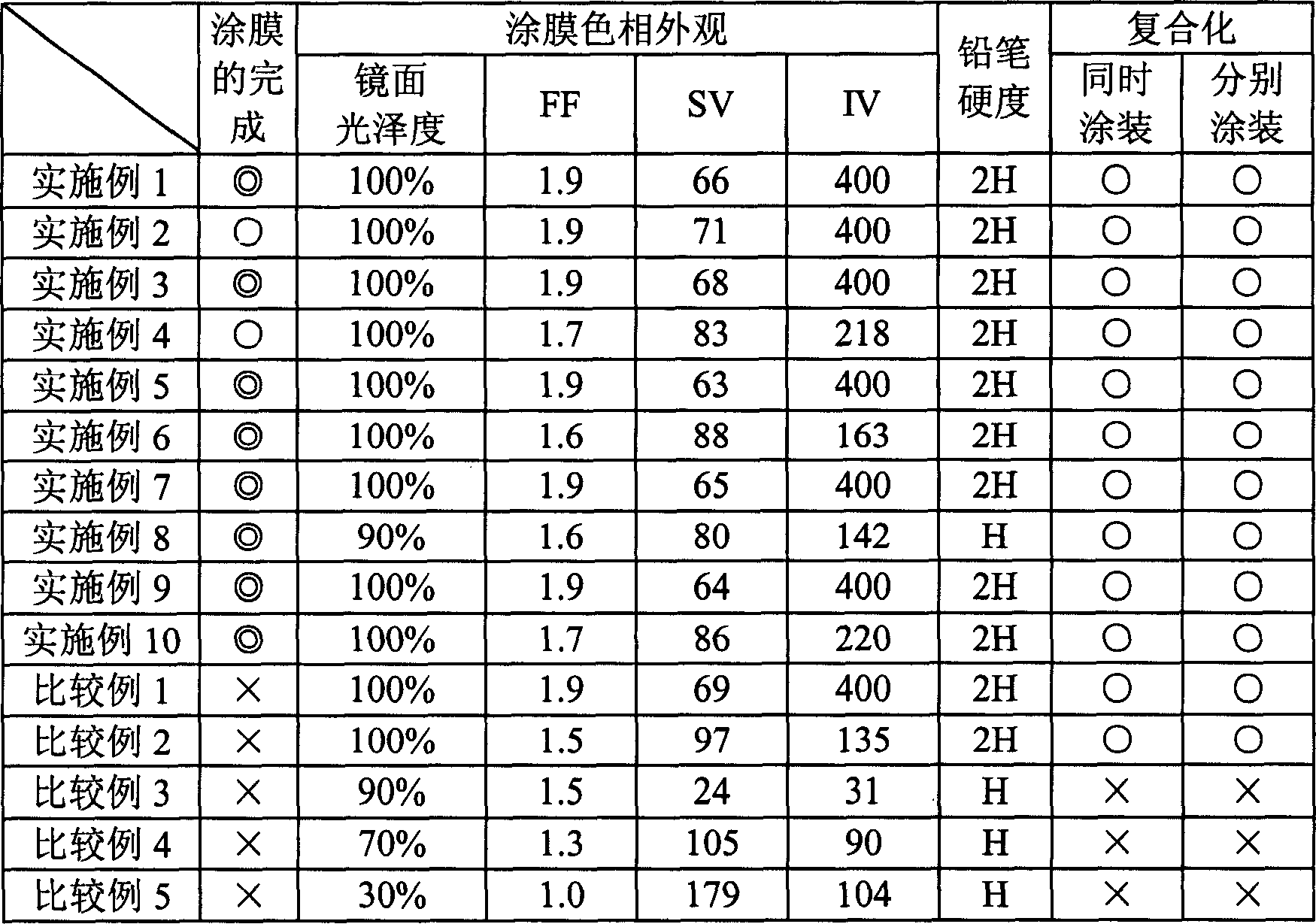

[0079] Hereinafter, the present invention will be described in detail by way of examples and comparative examples. In addition, in the compounding of each example, 'part' or '%' represent 'parts by mass' and '% by mass', respectively.

[0080] [Synthesis of Powder Coatings]

Synthetic example

[0082] By 33 parts of Epot-NT111 (epoxy resin of epoxy equivalent 475, manufactured by Dongdu Chemical Co., Ltd.), 33 parts of Epot-NT112 (epoxy resin of epoxy equivalent 650, manufactured by Dongdu Chemical Co., Ltd.), curing catalyst ( 0.05 parts of imidazole), 2.5 parts of surface conditioner, 1 part of matting agent, 20 parts of white pigment (titanium dioxide), 10 parts of extender pigment (alumina and silicon dioxide) and 4.1 parts of anhydride compound of imidazoline as curing agent The raw materials were mixed for about 3 minutes in a mixer (Super Mikisa) (manufactured by Nippon Spindle Manufacturing Co., Ltd.), and melt-kneaded at about 100° C. with a kneading extruder (manufactured by Busu Corporation).

[0083] The resulting molten kneading product was cooled to room temperature, coarsely pulverized, pulverized with a particle pulverizer ("Jietomil IDS-2 type", manufactured by Niyu Matchuk Co., Ltd., Japan), and classified with a 300-mesh sieve to obtain a volume ave...

Embodiment 1

[0086] On the surface of the sample (magnesium alloy die-casting, 50mm×200mm×2mm), a pencil hardness tester with a sapphire needle with a diameter of 5μm is placed on the front end, and a weight of 4.9N is added to form a person with a width of 50μm and a depth of 30μm. Work injury.

[0087] The powder coating produced in the above synthesis example was electrostatically coated on the sample caused by the above-mentioned artificial damage so that the coating film thickness after drying was 25 μm, and the temperature of the sample was kept within about 10 minutes in the drying oven. Raise the temperature from 20°C to 160°C, keep the temperature for 5 minutes, and dry the coating film. During this period, the change in viscosity of the powder coating over time was measured with a viscometer ("Solikit Meter MR300", manufactured by UBM Co., Ltd.), and the minimum melting viscosity was 1.7 Pa·s.

[0088] On the coating film formed by this powder coating, an acrylic resin-based sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com