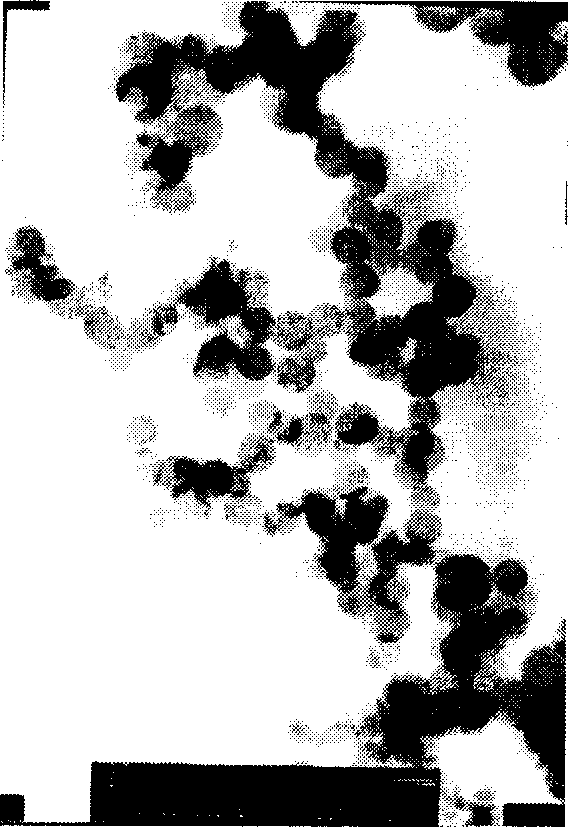

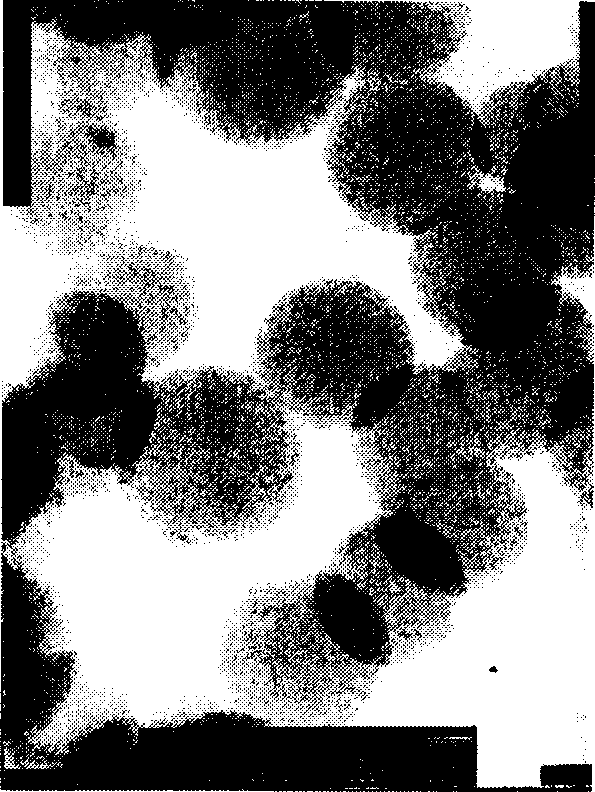

Process for preparing nanometer carbon microballoon by arc discharging technology

A carbon nanosphere and arc discharge technology, which is applied in the fields of coal chemical industry and carbon materials, can solve the problems of excessive by-products and poor mechanical structure, and achieve the effect of abundant resources, few structural defects and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A graphite rod (9mm in diameter) is used as the arc anode, and then the anode graphite rod is placed in the arc device for arc discharge evaporation and gasification. The reactor was first purged three times with nitrogen and then once with helium to remove the air in the reactor. Finally, a mixture of helium and acetylene (the volume ratio of acetylene to helium is 5:1) is introduced to a pressure of 0.065MPa (absolute pressure), cooling water is passed, the power is turned on, and the distance between the electrodes is adjusted to maintain the electrode The spacing is 2-3mm, so that the arc is in a "stable" discharge state until no substance is generated on the anode. The entire discharge time lasts about 10 minutes; after the discharge is over, turn off the power and stop the cooling water. Opening the reactor revealed a large amount of fibrous material deposited at the end of the anode. The collected products were weighed and the yield was calculated. Under the ab...

Embodiment 2

[0029] Coal-based carbon rods were used as the anode to prepare carbon nanospheres, and the selected coal was anthracite. The basic analysis data are as follows: M ad = 2.34%, A d = 3.13%, V daf = 15.70%; C daf =87.21%, H daf =3.53%, N daf= 1.06%. Take 500g of raw coal sample, pulverize it in a pulverizer, and sieve it until the particle size is less than 150μm, and dry it for later use. Take 200g of the above-mentioned dry coal sample and mix it with 100g of coal tar, put it into a mixer and stir evenly to obtain a mixture with certain cohesiveness, then put this mixture into a mold and extrude it with a hydraulic press to prepare a coal rod. The molding pressure is at About 10 atmospheres, the molding speed is 0.5cm / s, and the diameter of the obtained coal rod is 10mm. Cut off the above-mentioned coal rods to make short rods with uniform length (10cm) and put them into an electric furnace for programmed temperature rise carbonization. The whole carbonization process is...

Embodiment 3

[0031] When preparing carbon nanospheres with a certain hollowness, metal catalysts need to be added. The basic process is as follows: take a coal-based carbon rod as the anode, take 500 g of the raw coal sample (analysis of the sample is the same as in Example 2), pulverize in a pulverizer, and sieve to a particle size of less than 150 μm, and dry it for later use. Take 200g of the above-mentioned dry coal sample and mix it with 100g of coal tar, put it into a mixer and stir evenly to obtain a mixture with certain cohesiveness, then put this mixture into a mold and extrude it with a hydraulic press to prepare a coal rod. The molding pressure is at About 15 atmospheres, molding speed 0.5cm / s, the outer diameter of the obtained coal rod is 10mm, the inner diameter is the hollow coal rod of 6mm, then above-mentioned hollow coal rod is carbonized, and the carbonization process is exactly the same as the process of embodiment 1. The process of adding the catalyst is first to mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com