Rear earth green long afterglow luminescent material and preparing process thereof

A long afterglow luminescence, green technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as unseen long afterglow performance, and achieve the effects of wide excitation range, simple preparation method and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

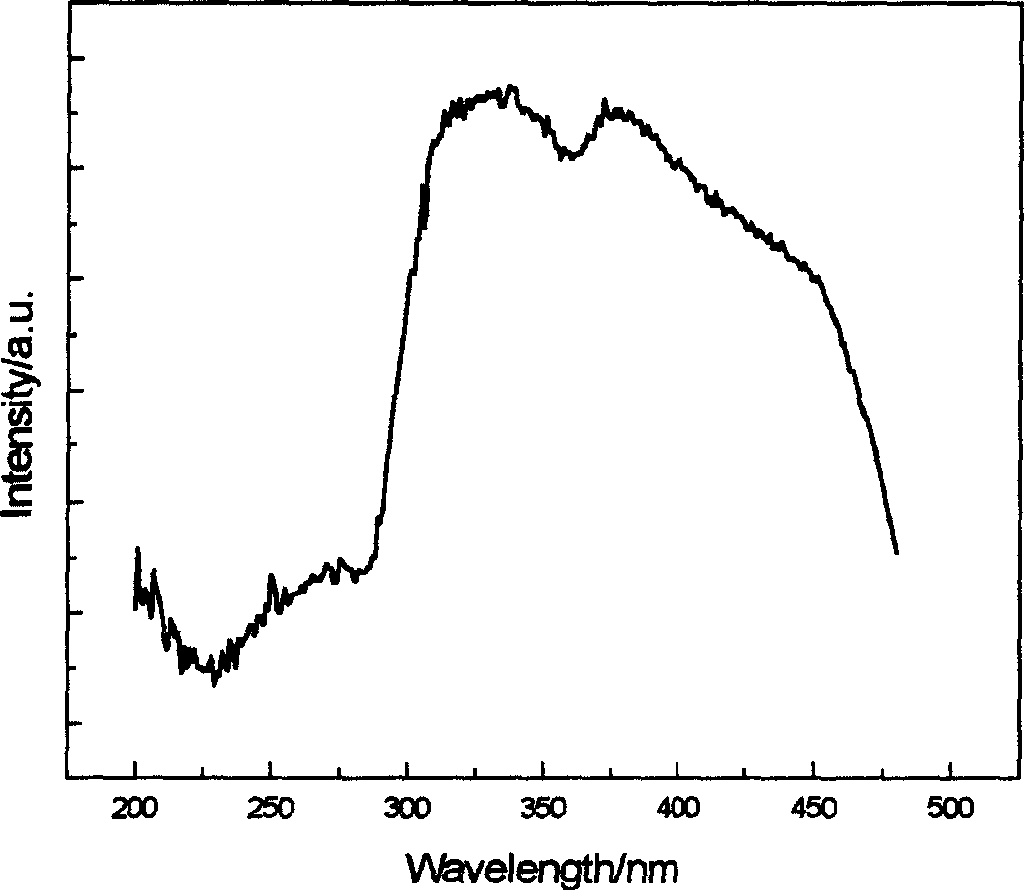

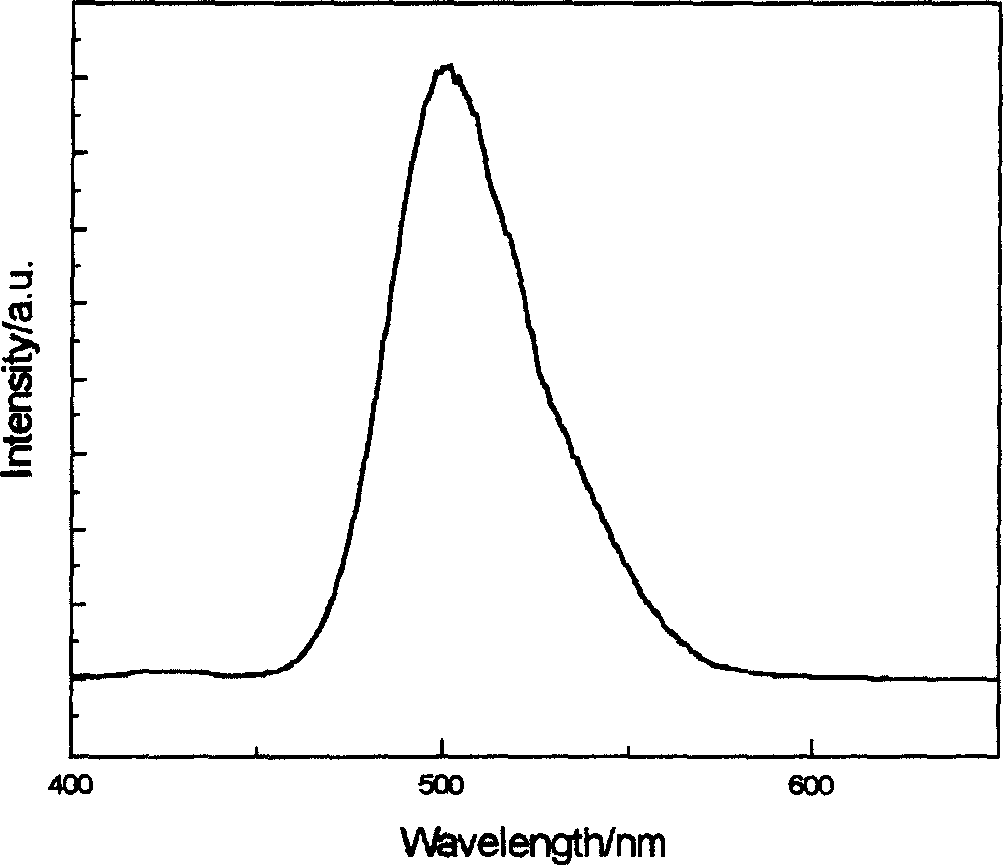

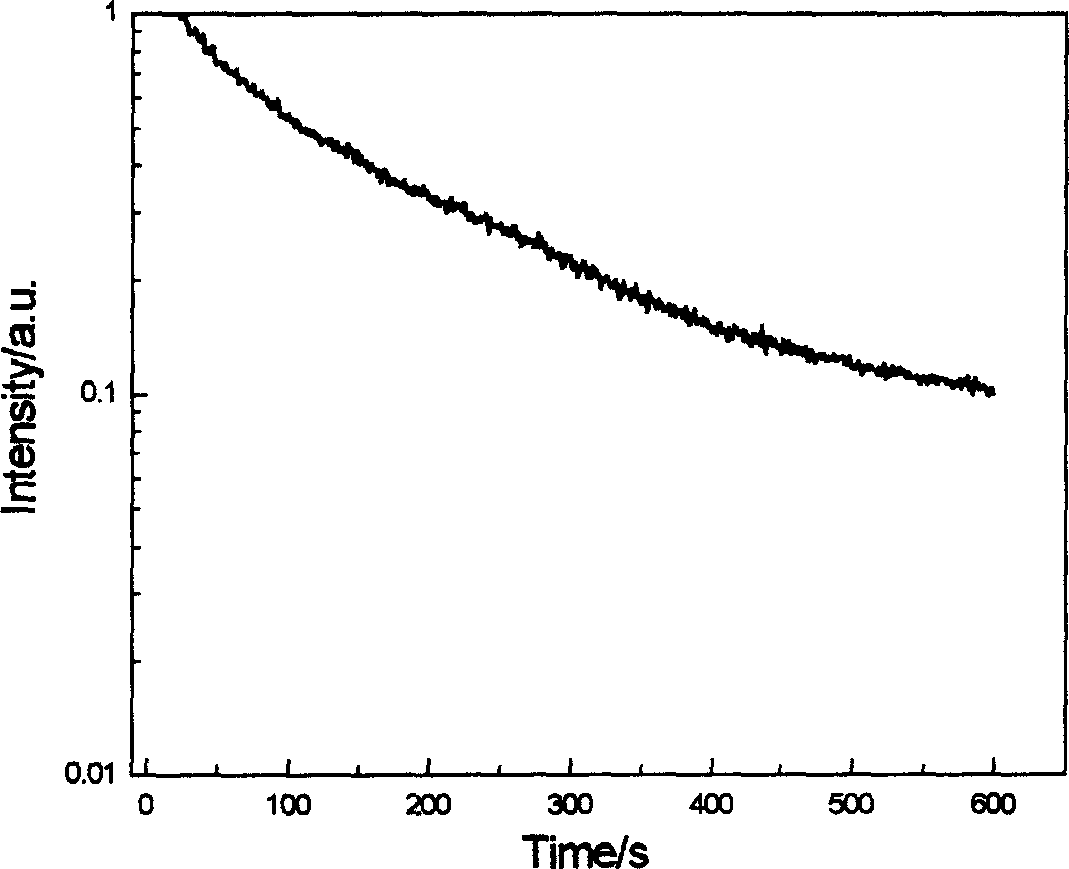

[0013] Weigh calcium carbonate (CaCO 3 ) 14.01g, magnesium oxide (MgO) 0.81g, silicon dioxide (SiO 2 ) 4.81g, anhydrous calcium chloride (CaCl 2 )3.33g, europium trioxide (Eu 2 o 3 ) 0.14g, aluminum oxide (Al 2 o 3 ) 0.05g, diboron trioxide (B 2 o 3 ) 0.07g, fully ground in an agate mortar and mixed evenly, then sintered in two steps in the reducing atmosphere of carbon rods: first, pre-sintered at a lower temperature of 400°C for 6 hours, cooled to room temperature, taken out and fully ground again And mix evenly, and sinter at 1000°C for 10 hours. The sample is taken out and ground, then washed with boiling water, filtered and dried to finally obtain the sample, which is analyzed by powder X-ray diffractometer as the main phase of Ca 8 Mg(SiO 2 ) 4 Cl 2 , after ultraviolet irradiation, the sample emits a strong green long afterglow.

Embodiment 2

[0015] Weigh calcium carbonate (CaCO 3 ) 14.01g, magnesium oxide (MgO) 0.81g, silicon dioxide (SiO 2 ) 4.81g, anhydrous calcium chloride (CaCl 2 )3.33g, europium trioxide (Eu 2 o 3 ) 0.28g, gallium trioxide (Ga 2 o 3 ) 0.15g, diboron trioxide (B 2 o 3 ) 0.07g in an agate mortar and thoroughly ground and mixed evenly, and then sintered in two steps in a reducing atmosphere of carbon monoxide (CO): firstly, pre-sintered at a lower temperature of 500°C for 5 hours, cooled to room temperature, and taken out again Fully grind and mix evenly, and sinter at 1100°C for 8 hours. The sample is taken out and ground, then washed with boiling water, filtered and dried to finally obtain the sample, which is analyzed by powder X-ray diffractometer as the main phase of Ca 8 Mg(SiO 2 ) 4 Cl 2 , after ultraviolet irradiation, the sample emits a strong green long afterglow.

Embodiment 3

[0017] Weigh calcium carbonate (CaCO 3 ) 14.01g, magnesium oxide (MgO) 0.81g, silicon dioxide (SiO 2 ) 4.81g, anhydrous calcium chloride (CaCl 2 )3.33g, europium trioxide (Eu 2 o 3 ) 0.56g, lanthanum trioxide (La 2 o 3 ) 0.52g, diboron trioxide (B 2 o 3 )0.07g, after fully grinding and mixing in an agate mortar, in hydrogen (H 2 ) in a reducing atmosphere, sintering in two steps: first, pre-sinter at a lower temperature of 700°C for 4 hours, cool to room temperature, take it out and grind it again and mix it evenly, and sinter at 1200°C for 6 hours. The sample is taken out and ground, then washed with boiling water, filtered and dried to finally obtain the sample, which is analyzed by powder X-ray diffractometer as the main phase of Ca 8 Mg(SiO 2 ) 4 Cl 2 , after ultraviolet irradiation, the sample emits a strong green long afterglow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com