Apparatus with self-assembly molecule as electron injection layer of organic LED and method thereof

A technology of electron injection layer and light-emitting diode, which is applied in lighting devices, electroluminescent light sources, circuits, etc., can solve the problem that the stability and reproducibility of the process are difficult to overcome, the energy level difference between the cathode metal and the organic light-emitting layer is large, and it is difficult to overcome the electronic Injection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Relevant detailed description and technical contents of the present invention, now cooperate with accompanying drawing to illustrate as follows:

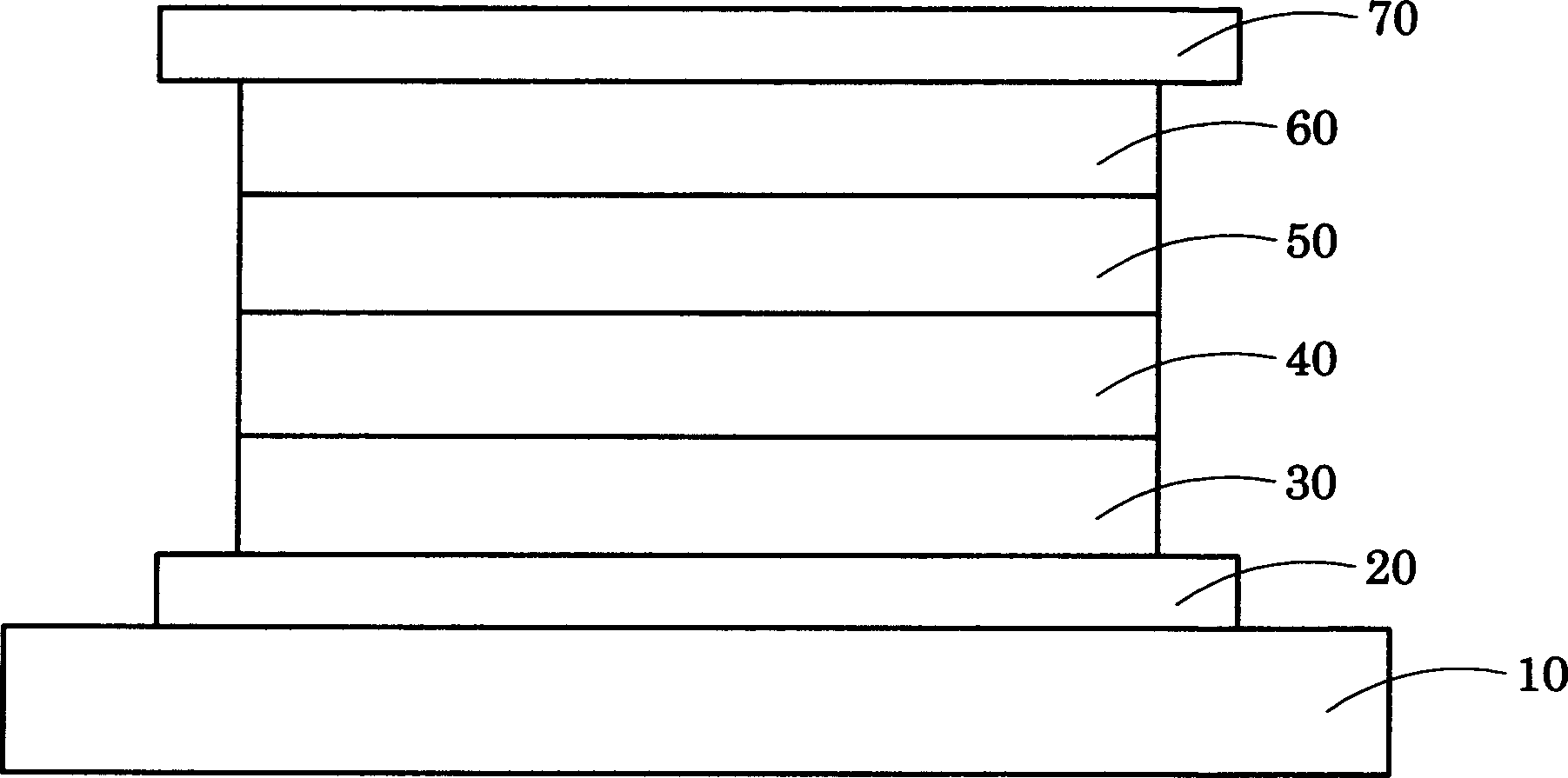

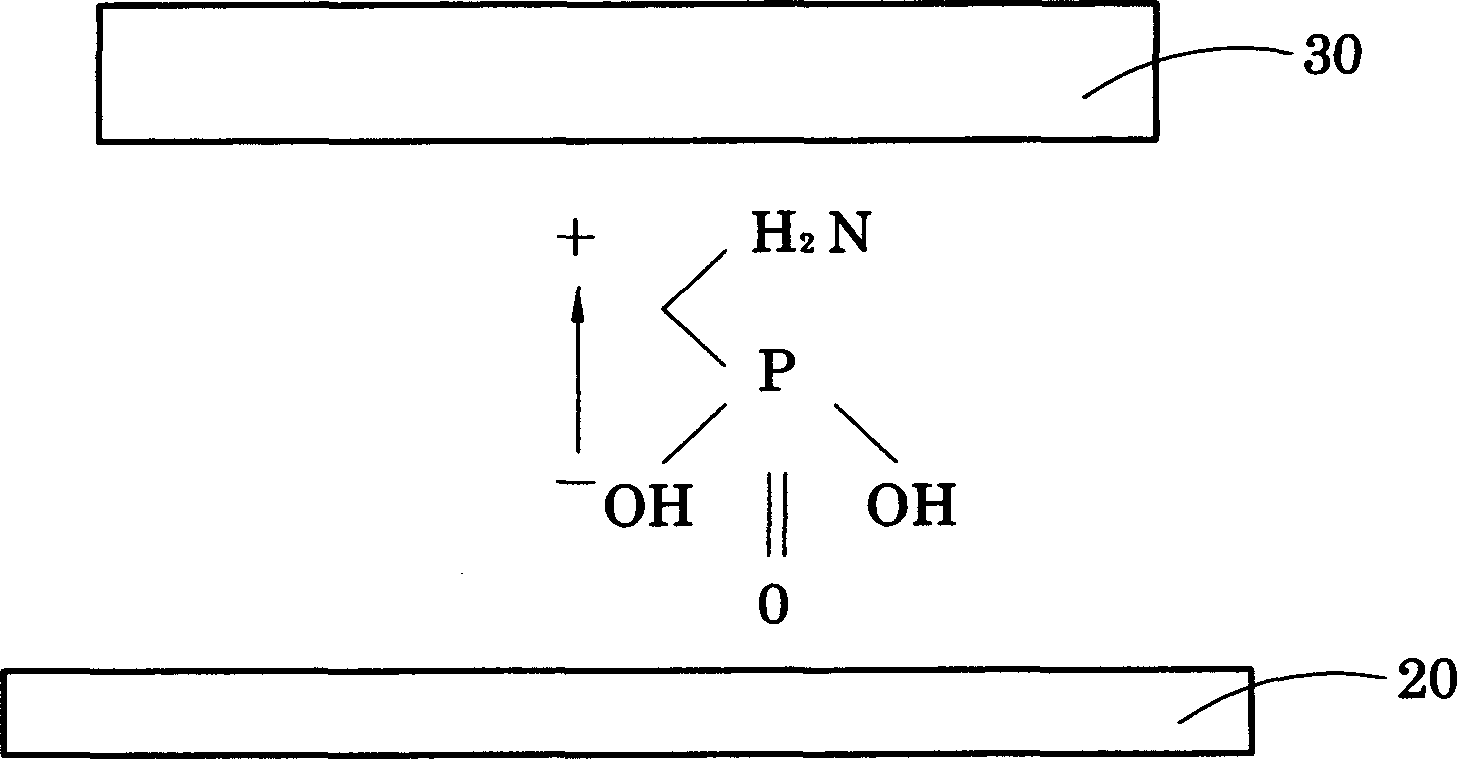

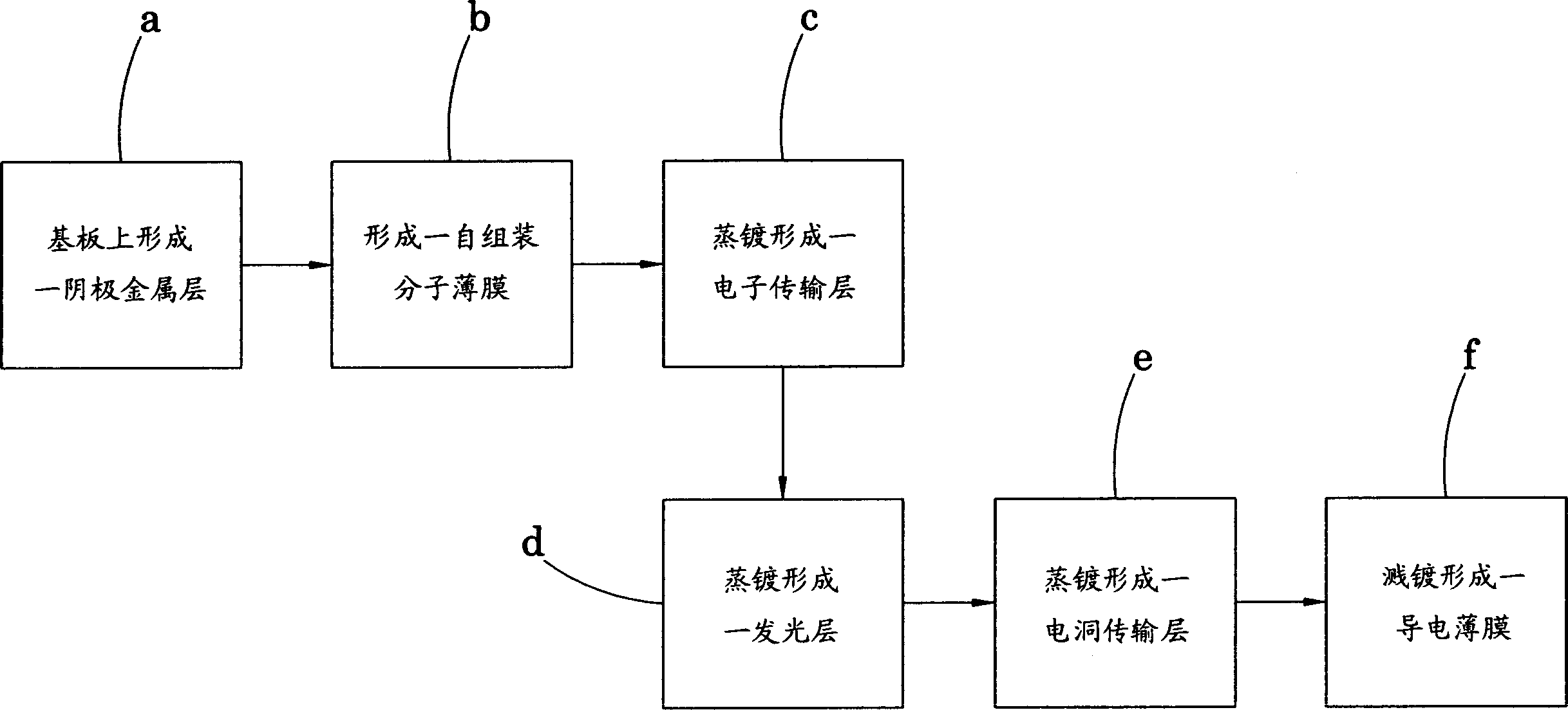

[0012] see figure 1 As shown, it is a schematic diagram of the structure of the present invention, as shown in the figure: the present invention first forms a cathode metal layer 20 on the organic light emitting diode (OLED) substrate 10, and the cathode metal layer 20 is a metal of the alkali metal group or alkaline earth group Composites formed of materials and aluminum (Al) or silver (Ag), indium tin oxide (ITO), indium zinc oxide (IZO), and then adhered to the surface of the cathode metal layer 20 by soaking or fumigation to form a The self-assembled molecular film 30 of self-dipole is aminomethylphosphonicacid (hereinafter referred to as: AMPA) with the existing self-assembled molecule at present, and this film is used as the electron injection layer of organic light-emitting diode (OLED) element, and then on this electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com