Process for preparing dazomet dustless stable fine granule

A preparation process and technology of microparticles, applied in biocides, animal repellents, plant growth regulators, etc., can solve the problems of stable dust drift and pollute the environment, and achieve the effects of saving equipment, high content, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

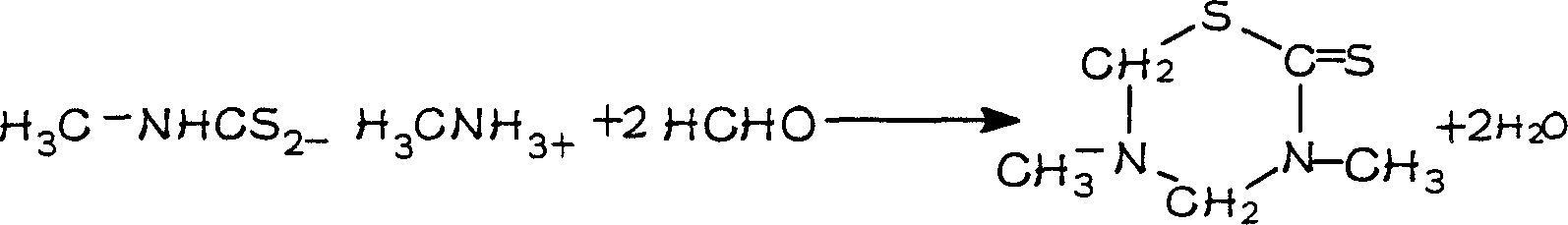

Method used

Image

Examples

experiment example 1

[0019] (1) Add 40g of 30% methylamine aqueous solution (0.4mol) and 50ml of water into a 250ml three-necked flask with stirring, start stirring, and slowly add 24.4g (0.32mol) of 99% carbon disulfide dropwise. Cool in a cold water bath to keep the reaction temperature not exceeding 30°C. After 1.5 hours of reaction, stand to separate the oil phase (9.2 g of the oil phase can be used for the next reaction), and obtain 106 g of 25.8% intermediate N-methyl disulfide Substitute carbamic acid, its yield is 99.39%.

[0020] (2) Add 106g25.9% intermediate N-methyldithiocarbamic acid, 1g nonylphenol polyoxyethylene ether (n=20), 5% polyvinyl alcohol aqueous solution ( 1799) 40ml, start stirring, start to add 33g of 37% formaldehyde aqueous solution (0.4mol) dropwise, about 20 minutes to finish dropping, while adding formaldehyde dropwise, the three-neck flask is cooled with a cold water bath, keep the reaction temperature not exceeding 30°C, and let stand after 1 hour of reaction Fil...

experiment example 2

[0022] (1) Add 40g of 30% methylamine aqueous solution (0.4mol) and 50ml of water into a 250ml there-necked flask with stirring, start stirring, and slowly add 24.4g (0.32mol) of 99% carbon disulfide (wherein 9.2g is obtained from Experimental Example 1) The separated oil layer), while adding carbon disulfide dropwise, the three-neck flask was cooled with a cold water bath to maintain the reaction temperature not exceeding 30°C, and after 100 minutes of reaction, the oil phase was separated and separated (9.2g of the oil phase can be used for the next reaction) , to obtain 106g25.9% intermediate N-methyldithiocarbamic acid, and its yield was 99.47%.

[0023] (2) Add 106g of 25.9% intermediate N-methyldithiocarbamic acid, 0.2g of nonylphenol polyoxyethylene ether (n=20), and 5% aqueous solution of polyvinylpyrrolidone into a 250ml there-necked flask with stirring (K30) 40ml, start stirring, start dropwise adding 33g of 37% formaldehyde aqueous solution (0.4mol), and drop it in ...

experiment example 3

[0025] (1) Add 40g of 30% methylamine aqueous solution (0.4mol) and 50ml of water into a 250ml there-necked flask with stirring, start stirring, and slowly add 15.2g (0.2mol) of carbon disulfide (9.2g of which is separated from Experimental Example 2) oil layer), and while adding carbon disulfide dropwise, the three-neck flask was cooled with a cold water bath, and the reaction temperature was maintained at no more than 30°C. After 1.5 hours of reaction, the layers were allowed to stand and the oil phase was separated (the oil phase can be used mechanically for the next reaction) to obtain 106g 25.5% intermediate N-methyldithiocarbamate, the yield is 98.24%.

[0026] (2) Add 106g of 25.6% intermediate N-methyldithiocarbamate, 2g of sodium lauryl sulfate, and 40ml of 1% polyvinyl alcohol aqueous solution (1799) into a 250ml there-necked flask with stirring, and start stirring , start to add 39g of 37% formaldehyde solution (0.48mol) dropwise, and finish dropping in about 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com