Natural ª‰-carotene microcapsule and method for making same

A technology of carotene and microcapsules, which is applied in the field of natural β-carotene microcapsules and its preparation, can solve the problems of inability to produce high-content β-carotene powder, large loss of β-carotene, and poor antioxidant effect. Achieve the effects of high embedding efficiency, high drying rate and strong anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

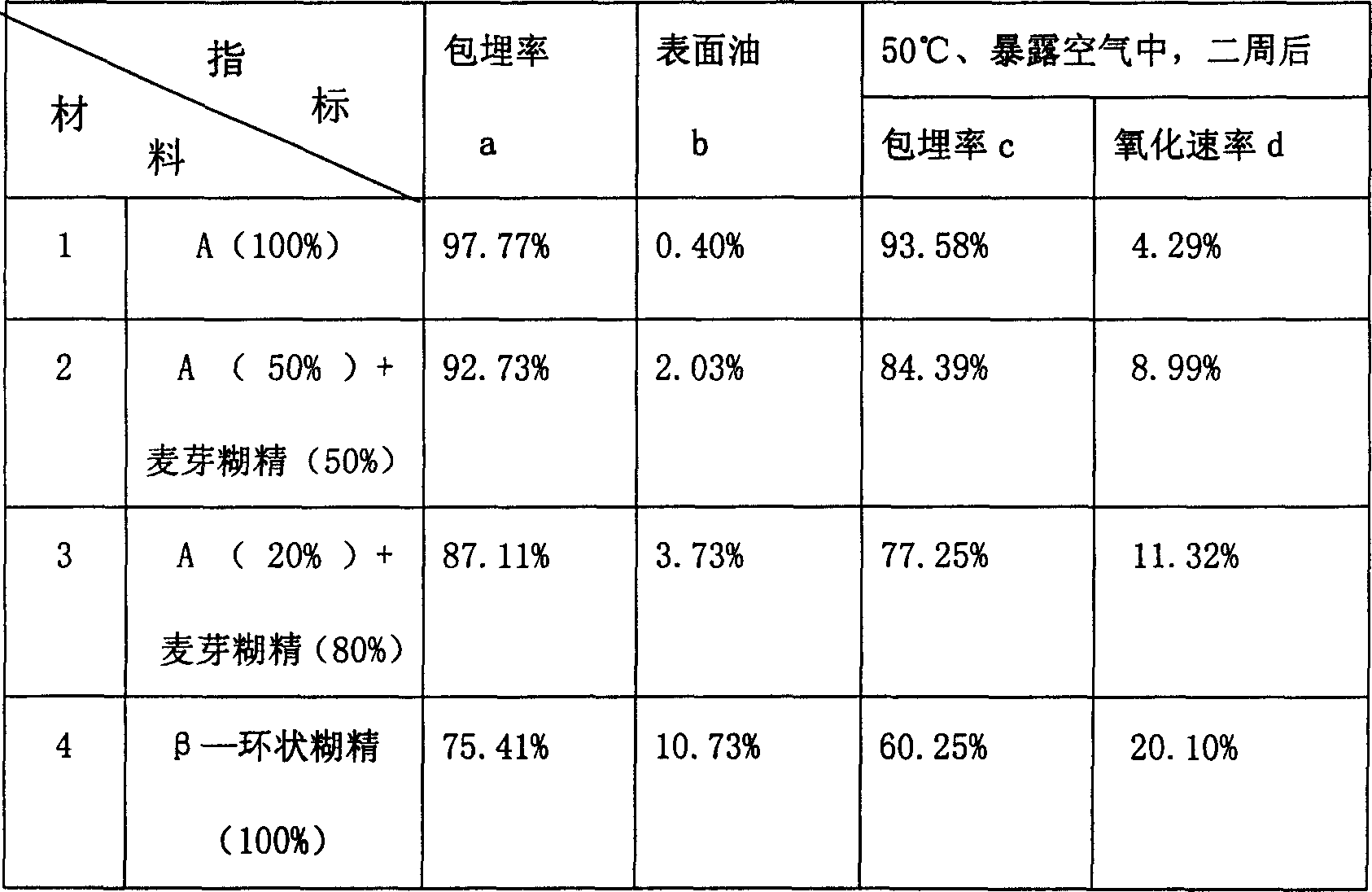

[0049] Put 100g of water in the container, slowly add 20g of modified starch under stirring state, stir well, and let it stand overnight to dissolve. 40 g of 5% natural beta-carotene oil was added with 2 g of soybean lecithin and 0.2 g of TBHQ, and heated to 120° C. in an oil bath to dissolve it to prepare an oil phase. Put 300g of water in the container, add 8g of maltodextrin, 16g of beta-cyclodextrin, 1.5g of sorbitol fatty acid ester, 15g of maltose, and 0.5g of sodium benzoate, stir and heat to 80°C, and heat the standby modified starch solution to 70°C, added to the above solution to make an aqueous phase. The oil phase was added to the water phase, the temperature was kept at 80°C, and emulsification was carried out with an emulsifying machine, the rotation speed was 4000 rpm, and the time was 20 minutes. The emulsified liquid is homogenized, and the pressure is 40kg / cm2 , the homogenized material is spray-dried, the inlet temperature is 195°C, and the outlet temperatu...

Embodiment 2

[0051] Put 200g of water in the container, slowly add 26g of modified starch under stirring state, stir well, and let it stand overnight to dissolve. 50 g of 20% natural beta-carotene oil was added with 1 g of Tween 60 and 0.5 g of natural VC, and heated to 190° C. in an oil bath to dissolve it to prepare an oil phase. Put 200g of water in the container, add 5g of maltodextrin, 6g of beta-cyclodextrin, 1g of soybean lecithin, 8g of lactose, and 1g of potassium sorbate, stir and heat to 75°C, and heat the standby modified starch solution to 50°C, Add to the above solution to make an aqueous phase. The oil phase was added to the water phase, the temperature was kept at 75° C., and emulsification was carried out with an emulsifying machine, the rotation speed was 3000 rpm, and the time was 30 minutes. The emulsified liquid is homogenized, and the pressure is 40kg / cm 2 , the homogenized material is spray-dried, the inlet temperature is 200°C, and the outlet temperature is 90°C, ...

Embodiment 3

[0053] Put 100g of water in the container, slowly add 20g of modified starch under stirring state, stir well, and let it stand overnight to dissolve. 10 g of 5% natural beta-carotene oil was added with 0.8 g of soybean lecithin and 0.1 g of TBHQ, then heated to 120° C. in an oil bath to dissolve it to prepare an oil phase. Put 300g of water in the container, add 5g of maltodextrin, 5g of beta-cyclodextrin, 0.7g of sorbitol fatty acid ester, 5g of glucose, and 0.5g of sodium benzoate, stir and heat to 50°C, and heat the standby modified starch solution to 40°C, added to the above solution to make an aqueous phase. The oil phase was added to the water phase, the temperature was kept at 60°C, and emulsification was carried out with an emulsifying machine, the rotation speed was 2000 rpm, and the time was 10 minutes. The emulsified liquid is homogenized, and the pressure is 30kg / cm 2 , the homogenized material is spray-dried, the inlet temperature is 150°C, and the outlet temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com