Method for preparation of lithium manganate having uniform spinel structure

A technology of spinel structure and manufacturing method, applied in electrode manufacturing, structural parts, chemical instruments and methods, etc., can solve problems such as uneven structure, achieve faster synthesis rate, improve porosity and specific surface area, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Pretreatment of MnO 2 Manufacture of:

[0023] Weigh 1600g MnO 2 The percentage content is 92.8, and the bulk density is 2.21g / cm 3 , Electrolytic manganese dioxide with a particle size of -200 mesh, placed in a muffle furnace, heated to 720 ° C, kept for 2 hours, taken out and cooled to room temperature to obtain brown Mn-containing 2 o 3 1376g of the product; then it is formulated into a slurry at a ratio of 1:2 according to the solid-liquid ratio, and the temperature is raised to 85°C under stirring conditions, and 9.5mol of concentrated H is added 2 SO 4 , maintained at 90-98°C for 2 hours, then stopped stirring, allowed it to cool and settle naturally, washed with distilled water to a pH value of 5-6 after separation, dried at 120°C for 6 hours after filtration, and obtained pretreated MnO 2 Product 823g.

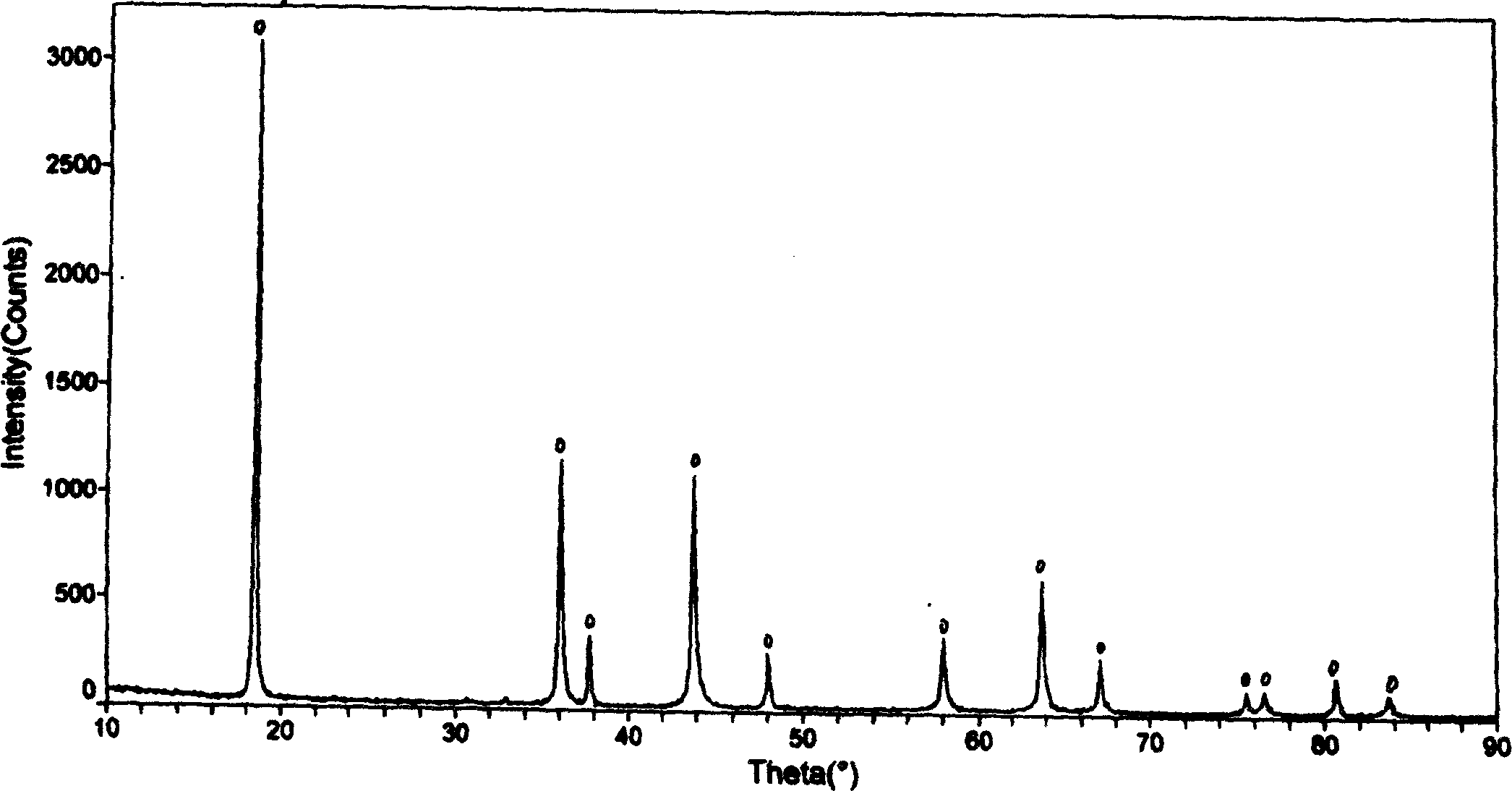

[0024] The pretreated MnO 2 powder was tested, its MnO 2 The percentage content is 91.4, the Mn% is 62.8, and the bulk density is 1.55g / cm 3 ...

Embodiment 2

[0025] Embodiment 2 A kind of manufacturing method of lithium manganese oxide material with uniform spinel structure:

[0026] with MnO 2 The percentage content is 92.5, and the bulk density is 2.27g / cm 3 1. Electrolytic manganese dioxide with a particle size of over 325 mesh was used as manganese source material, except that the roasting temperature used was 800° C. and the acid used was concentrated nitric acid, and other conditions were the same as in Example 1 to prepare pretreated MnO 2 . After testing, its MnO 2 The percentage content is 91.2, the Mn% is 62.6, and the bulk density is 1.52g / cm 3 . Accurately weigh the pretreated MnO 2 100g, add 39.2g analytical pure LiNO 3 , then add 80ml of distilled water for gelatinization, after aging for 12 hours, heat and dry while stirring, until the material is lumpy; Down treatment for 24 hours, cooling, ball milling, and passing through a 200-mesh sieve to obtain black lithium manganate lithium ion battery cathode materia...

Embodiment 3

[0028] Embodiment 3 A kind of manufacturing method of lithium manganese oxide material with uniform spinel structure:

[0029] Accurately take by weighing 100g the pretreatment MnO that the method described in embodiment two makes 2 , add 26.3g analytically pure LiOH.H 2 O, add 100ml of distilled water for gelatinization, age for 2 hours, heat and dry while stirring, until the material is lumpy; Down treatment for 10 hours, cooling, ball milling, and passing through a 200-mesh sieve to obtain black lithium manganate lithium ion battery cathode material.

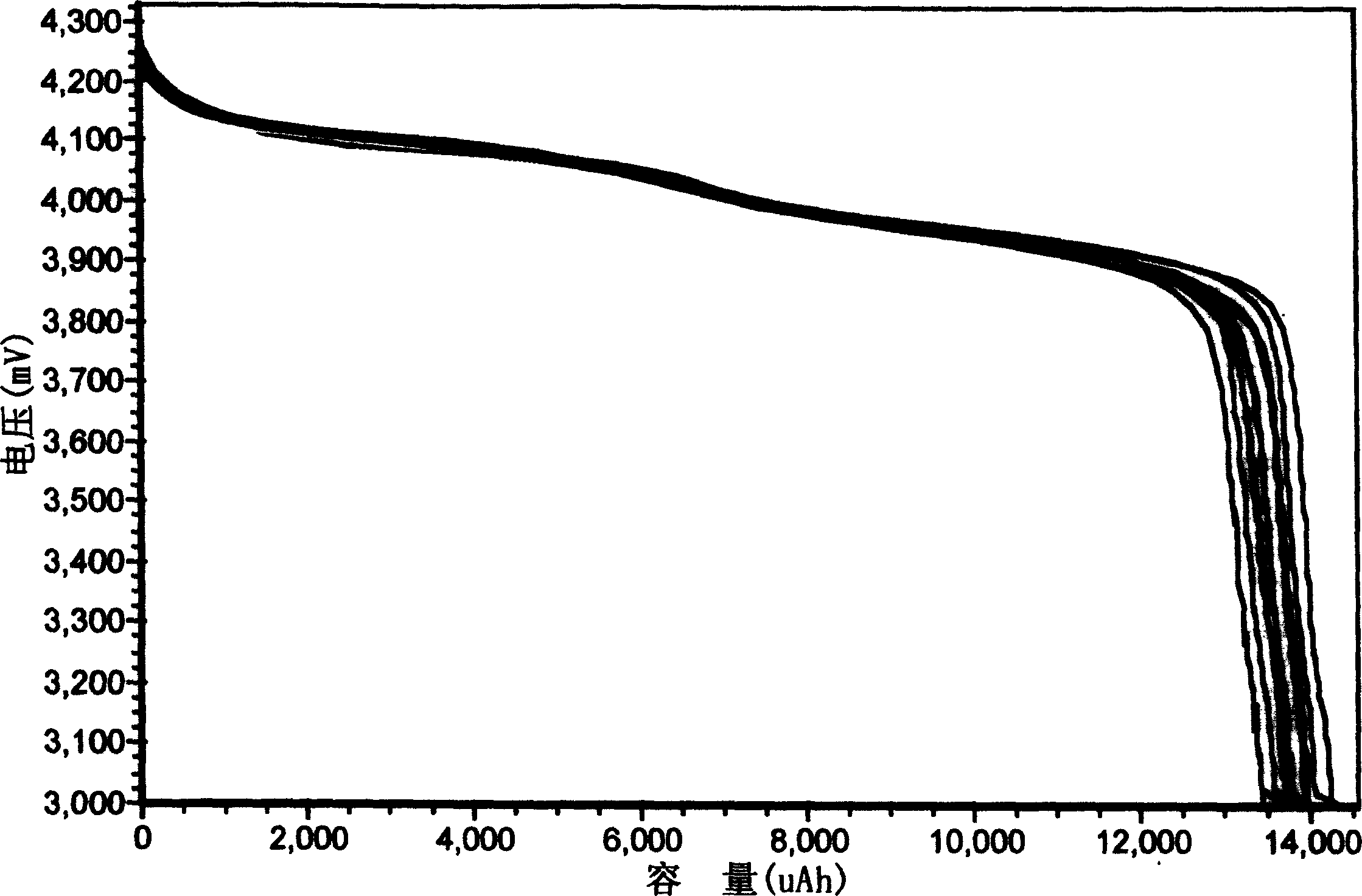

[0030] The XRD test of the obtained material shows that its chemical composition is single and has a uniform spinel structure. The obtained material was used as the positive electrode, and the metal lithium sheet was used as the negative electrode to assemble an experimental battery. The charge and discharge test was carried out in the range of 3.0-4.5V. The first inverse specific capacity of the material was measured to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com