Silex glass tube pulse xenon light with high power composite function

A quartz glass tube and composite function technology, applied in the manufacture of discharge tubes/lamps, discharge lamps, discharge tubes, etc., can solve the problems affecting the service life of cerium-doped quartz glass tube pulse xenon lamps, the decrease of load energy, and the explosion of lamps, etc. Achieve the effects of good radiation spectrum performance, strong shock wave resistance and large load energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

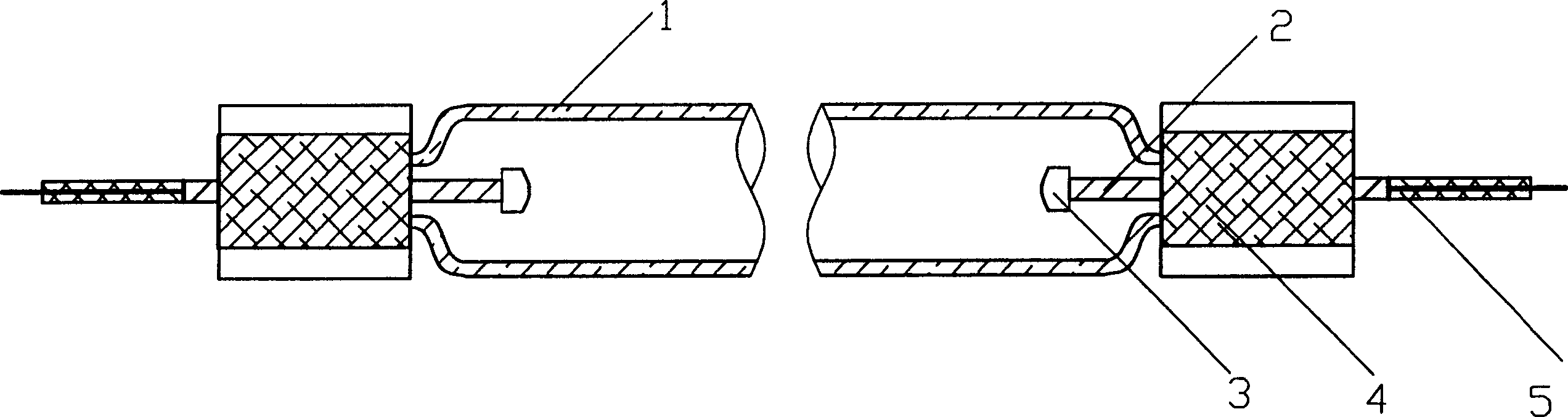

[0022] The wall material of the high-power composite function quartz glass tube pulse xenon lamp of the present invention used in this embodiment is a cylindrical composite function quartz glass tube with an arc length of 1430 mm, an outer diameter of 37 mm and a tube wall thickness of 3 mm. The lamp tube is filled with high-purity xenon gas, and both the electrode rod 2 and the electrode cap 3 are made of cerium-tungsten material. Lamp holder 4 adopts transition glass sealing process. 5 leads out the cable for the lamp holder. The total length of the xenon lamp is about 1670mm.

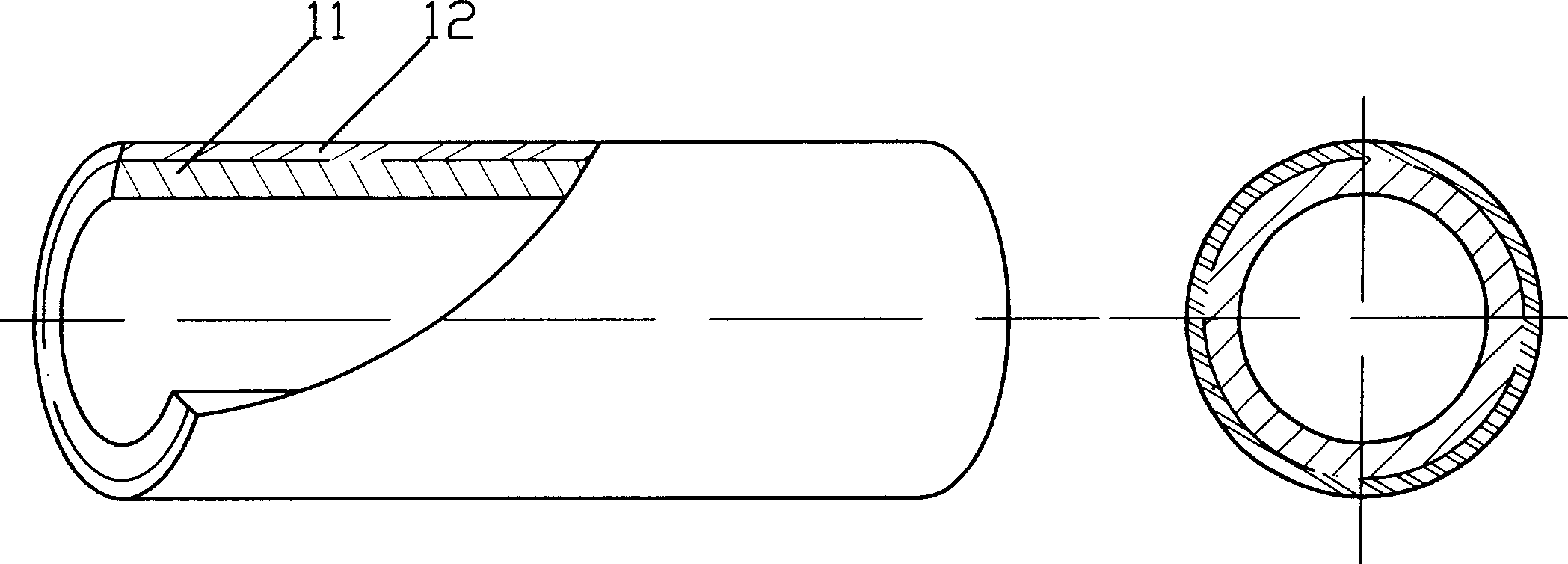

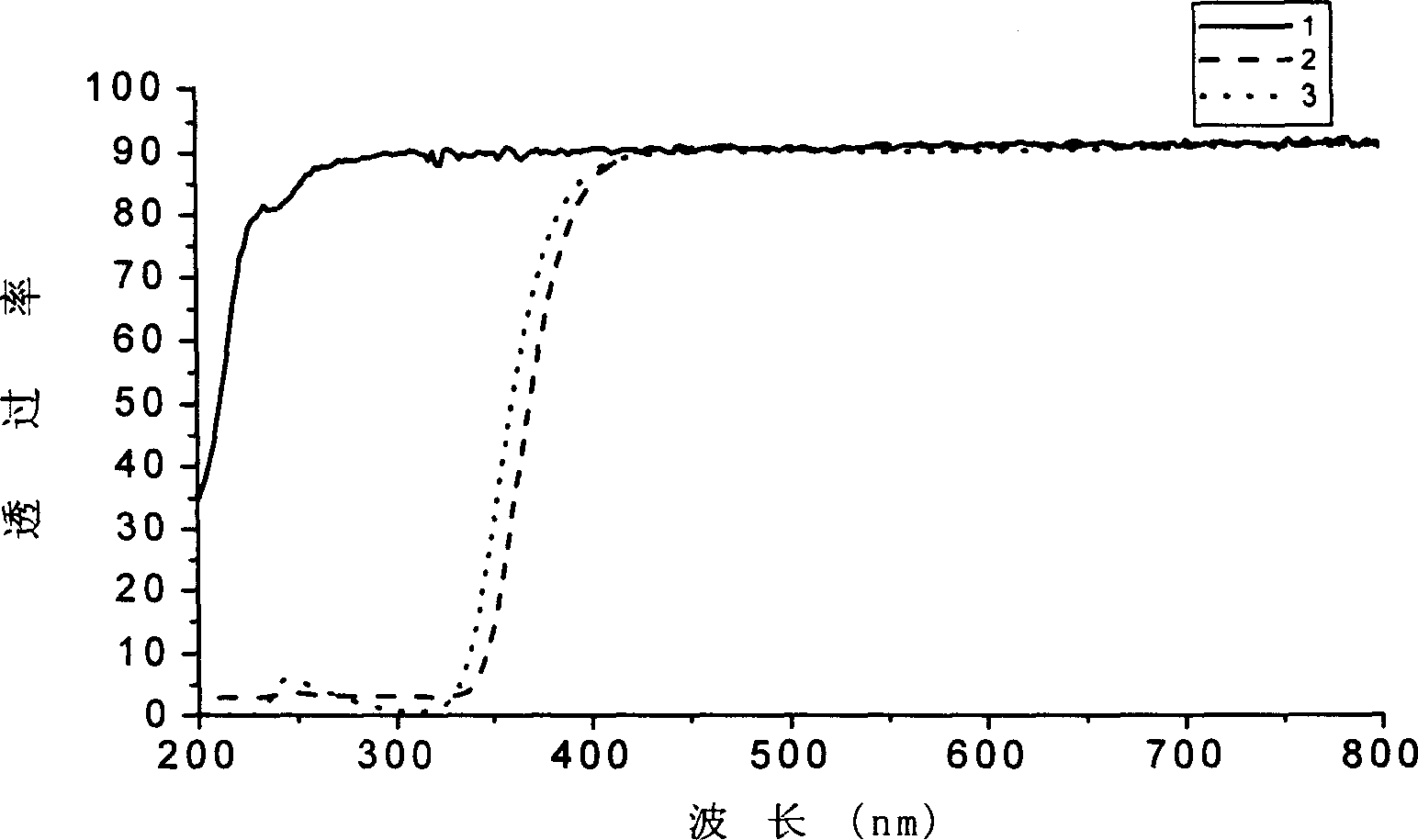

[0023] Pulse xenon lamp tube—the composite functional quartz glass tube adopts the 1# glass tube in Table 1, its thickness is 3mm, and the ratio of the thickness of the inner layer of high-purity quartz glass layer 11 to the outer layer of cerium-doped quartz glass layer 12 is 2:1 , the thickness of the outer cerium-doped quartz glass layer 12 accounts for 33% of the thickness of the entire composi...

Embodiment 2

[0029]The wall material of the pulsed xenon lamp of the high-power composite functional quartz glass tube of the present invention used in this embodiment is a cylindrical composite functional quartz glass tube with an arc length of 1270 mm and an outer diameter of 22 mm. The lamp tube is filled with high-purity xenon gas, and both the electrode rod 2 and the electrode cap 3 are made of cerium-tungsten material. The lamp holder 4 adopts a transitional glass sealing process. Composite function quartz glass adopts 3# glass tube in Table 1, its thickness is 2.5mm, the ratio of the thickness of the inner high-purity quartz glass layer 11 and the outer layer cerium-doped quartz glass layer 12 is 1.5:1, and the outer layer cerium-doped quartz glass layer The proportion of layer thickness is 40%. Since this pulsed xenon lamp is long and thin, and the xenon gas pressure in the tube is high, there are high requirements on the mechanical strength and impact resistance of the tube wall ...

Embodiment 3

[0030] Embodiment 3 adopts the 2# glass tube in Table 1, and the specific conditions are similar, and are not repeated here.

[0031] In conclusion, the pulsed xenon lamp of the present invention has excellent impact resistance, high load energy and a radiation spectrum matched with neodymium glass (Nd:glass).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com