Gemini quaternary surfactant containing pyridine rings and preparing method thereof

A surfactant, gemini quaternary ammonium salt technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of application and promotion limitations, decreased use effect, etc., to achieve high surface activity, strong anti-corrosion ability , the effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

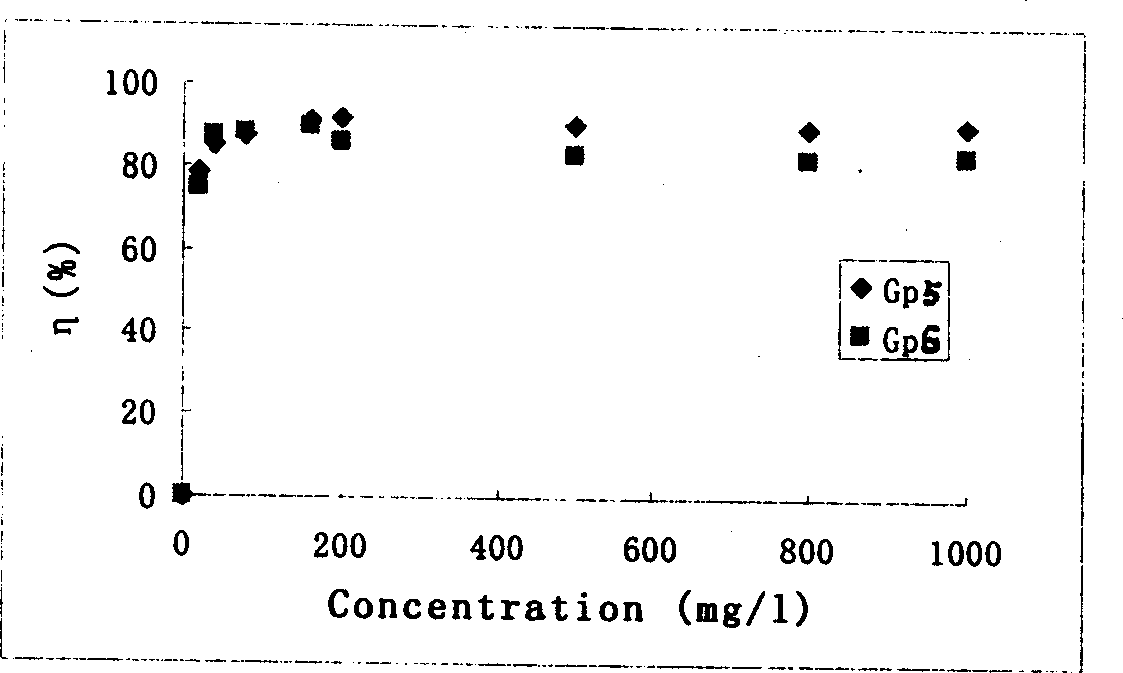

Examples

Embodiment 1

[0035] Into a 500ml three-necked flask equipped with a dropping funnel, a nitrogen inlet tube, and a reflux condenser with a drying tube, after first purging with nitrogen, add 100ml of anhydrous ether and 2.45g of lithium (0.35mol), and drop Add 0.2mol of C 10 h 21 A mixture of Br and 40-60ml of anhydrous ether was reacted for about 1 hour to make most of the lithium chips react completely, and the reaction temperature was controlled near the freezing point, and 21g (0.26mol) of pyridine and 50ml of toluene were added dropwise, and after 2 hours of reaction, the temperature was raised To 110°C, reflux for 3 hours. Separation, washing and drying. The low-boiling point compounds were evaporated on a rotary evaporator, and the corresponding fractions were collected by distillation under reduced pressure, and then subjected to column chromatography (eluent: petroleum ether: ethyl acetate = 4:1) to obtain α-decylpyridine.

[0036] Add decylpyridine and 1,4-dibromobutane (or 1,6...

Embodiment 2

[0038] In a 500ml three-necked flask equipped with a dropping funnel, a nitrogen inlet tube, and a reflux condenser with a drying tube, after purging with nitrogen, add 50ml of anhydrous ether and 2.45g of lithium (0.35mol), and start stirring. Add 0.2molC dropwise 12 h 25 The mixture of Br and 50ml of anhydrous ether was reacted for about 2 hours to make most of the lithium chips react completely, and the reaction temperature was controlled at about freezing point, and 0.3mol of pyridine and 60ml of toluene were added dropwise, and after 2 hours of reaction, the temperature was raised to about 110°C. Reflux for 3 hours. Separation, washing and drying. The low-boiling point compounds were evaporated on a rotary evaporator, and the corresponding fractions were collected by distillation under reduced pressure, and then subjected to column chromatography to obtain α-dodecylpyridine.

[0039] In a three-necked flask equipped with a stirrer and a reflux condenser, add dodecylpyr...

Embodiment 3

[0041] Add dodecylpyridine and 1,4-dibromobutane (its molar ratio is 3: 1) synthesized in Example 2 in a three-necked flask equipped with a stirrer and a reflux condenser, and the solvent in the reaction mixture (without The massfraction of water ethanol) is 60%, reflux reaction 20 hours, steams dehydrated alcohol with rotary evaporator, recrystallization, the white solid of drying gained, promptly obtains the gemini quaternary ammonium salt surfactant GP8 that contains pyridine ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com