Compound flame retardant waterproof roll made from polyvinyl propylene macromolecule, and prodn. thereof

A polyethylene polypropylene fiber and waterproof membrane technology, which is applied in chemical instruments and methods, other chemical processes, roofs using flexible materials, etc., can solve the problem of only considering the waterproof performance of membranes, difficulty in promotion and popularization, fire safety hazards, etc. problems, to achieve the effect of light weight, excellent waterproof performance, and large friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

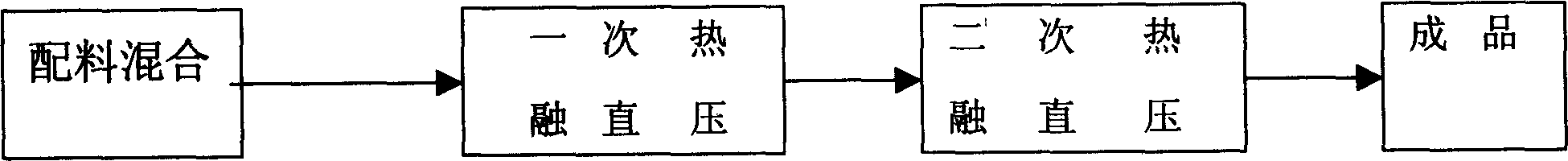

[0015] a. Ingredients mixing: put 62.5% linear low density polyethylene resin, 1.5% light shielding agent, 1.5% antioxidant, 1.0% adhesion promoter, 33% flame retardant masterbatch, 0.5% dispersant Stir evenly in the container, the unit is percentage by weight; b, one-time hot-melt direct pressure: put the stirred material into the screw extruder, and melt and extrude it into a resin film through the screw extruder at a temperature of 155°C; c, two Secondary hot-melt direct pressure: While extruding the resin film, introduce the non-woven fabric into a pair of drafting rollers from both sides at the same time, and through the extrusion of the rollers, the non-woven fabric and the resin film are hot-pressed and combined into one, the temperature is 165 ℃ to form a waterproof membrane. The flame retardant masterbatch is mainly composed of 81.1% polyolefin resin, 2.5% polyethylene wax, 14% coupling agent, 1.2% white oil and 1.2% zinc stearate. Due to the relatively high content ...

Embodiment 2

[0017] a. Ingredients mixing: put 70.4% linear low density polyethylene resin, 0.5% light shielding agent, 0.5% antioxidant, 0.5% adhesion promoter, 28% flame retardant masterbatch, 0.1% dispersant Stir evenly in the container, the unit is percentage by weight; b, one-time hot-melt direct pressure: put the stirred material into the screw extruder, and melt and extrude it into a resin film through the screw extruder at a temperature of 165°C; c, two Secondary hot-melt direct pressure: While extruding the resin film, introduce the non-woven fabric into a pair of drafting rollers from both sides at the same time, and through the extrusion of the rollers, the non-woven fabric and the resin film are hot-compressed into one body, and the temperature is 155 ℃ to form a waterproof membrane. The flame retardant masterbatch is mainly composed of 80% polyolefin resin, 2.5% polyethylene wax, 15.1% coupling agent, 1.2% white oil and 1.2% zinc stearate. The flame retardant masterbatch used...

Embodiment 3

[0019] a. Ingredients mixing: put 66.5% linear low density polyethylene resin, 0.7% light shielding agent, 0.9% antioxidant, 0.6 adhesion promoter, 31.0% flame retardant masterbatch, 0.3% dispersant Stir evenly in the container, the unit is percentage by weight; b, one-time hot-melt direct pressure: put the stirred material into the screw extruder, and melt and extrude it into a resin film through the screw extruder at a temperature of 160°C; c, two Secondary hot-melt direct pressure: While extruding the resin film, introduce the non-woven fabric into a pair of drafting rollers from both sides at the same time, and through the extrusion of the rollers, the non-woven fabric and the resin film are hot-compressed into one body, the temperature is 160 ℃ to form a waterproof membrane. The composition of the flame retardant masterbatch is mainly composed of 80.9% of polyolefin resin, 1.5% of polyethylene wax, 16% of coupling agent, 0.8% of white oil, and 0.8% of zinc stearate. Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com