Cold rolled acid waste water disposal neutralizer in metallurgical industry and its process method

A technology of acid wastewater and metallurgical industry, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as leakage, achieve full reaction, reduce investment cost, and easily The effect of operational management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

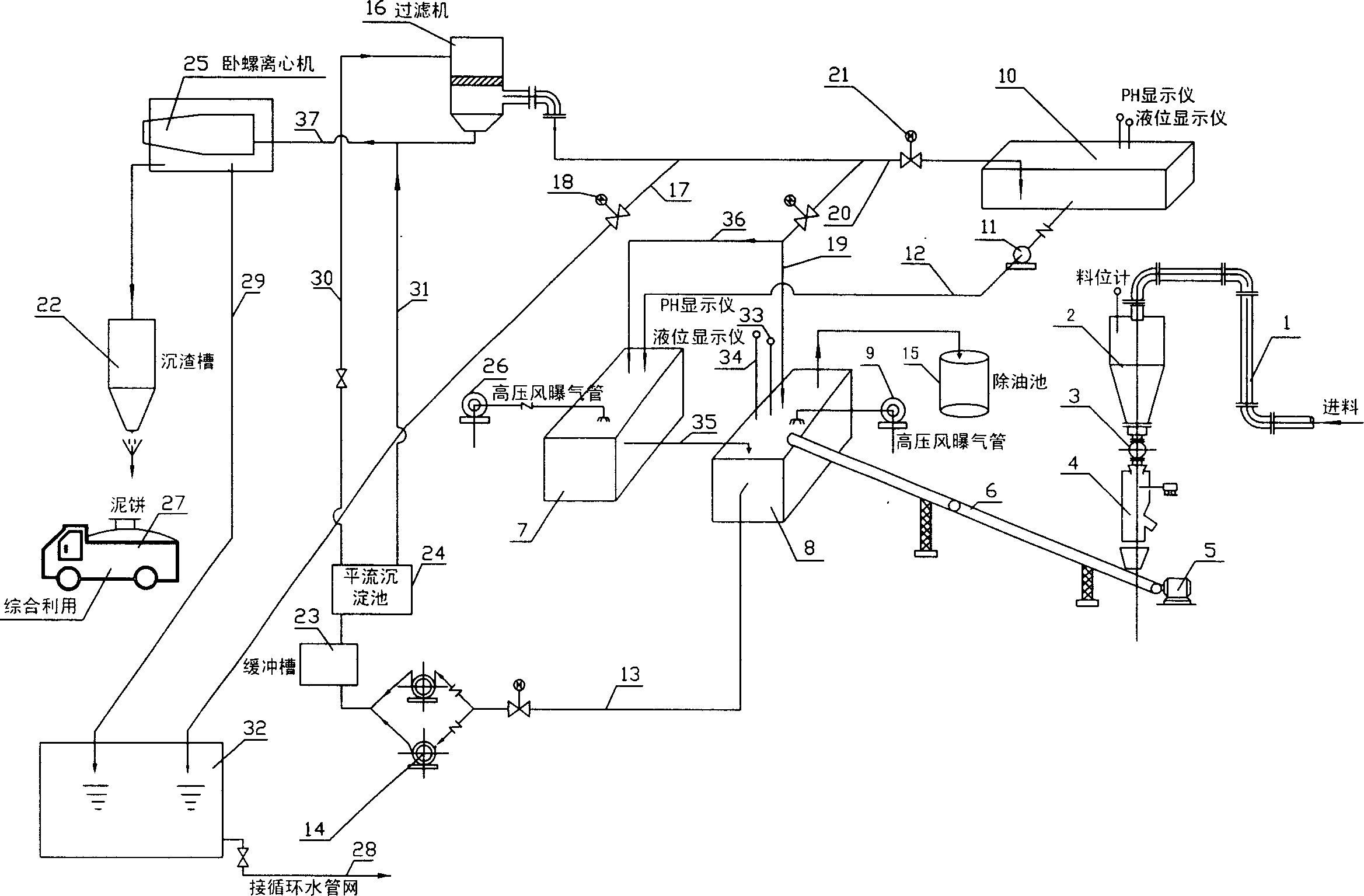

[0024] The present invention is realized like this, see figure 1 . The acid wastewater storage tank 10 supplies the acid wastewater to the pre-aeration tank 7 through the water pump 11 and the pipeline 12, and the high-pressure air aeration pipe 26 implements air aeration, and after the air aeration, the acid wastewater enters the neutralization reaction tank through the pipeline 35. The neutralizer passes through the pipeline 1 material trough 2 rotary valve 3 solid flow meter 4 feeding device 5 conveying belt 6 enters the neutralization reaction tank 8 for neutralization reaction, and at the same time the high-pressure air aeration pipe 9 implements direct aeration, divided into agitation plus aeration, mechanical agitation, Direct aeration has three reaction modes.

[0025] The reacted mixed solution passes through the buffer tank 23 and the advection sedimentation tank 24. At this time, the supernatant enters the filter 16 through the pipeline 30, and the sediment in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com