Photoresist stripping liquid composition and stripping methof for photoresist using photoresist stripping liquid composition

A photoresist and composition technology, applied in the field of photoresist peeling, can solve the limitation of cleaning residues, insufficient photoresist and residue peeling ability, unfavorable environmental aspects and processing costs and other problems to achieve the effect of low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

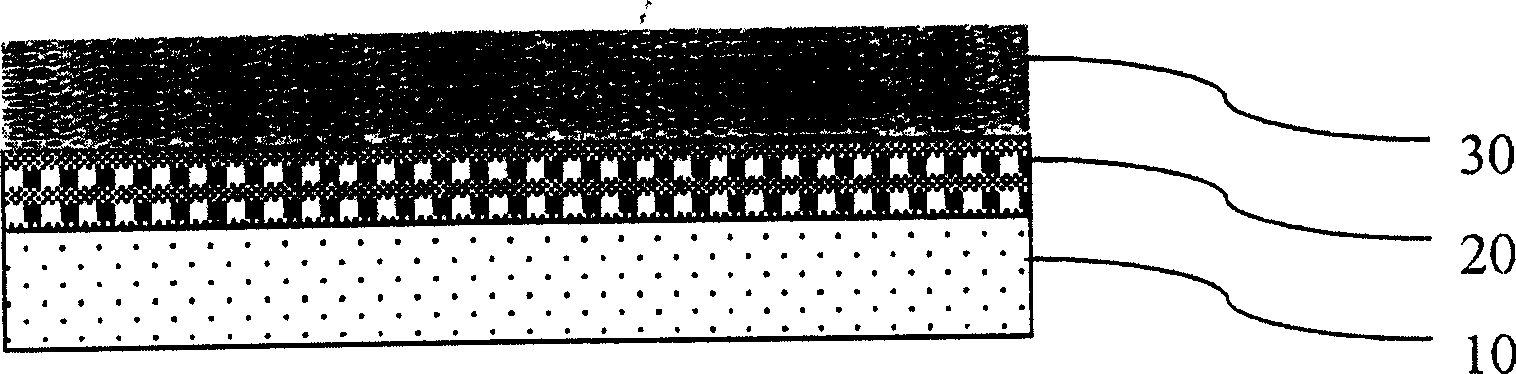

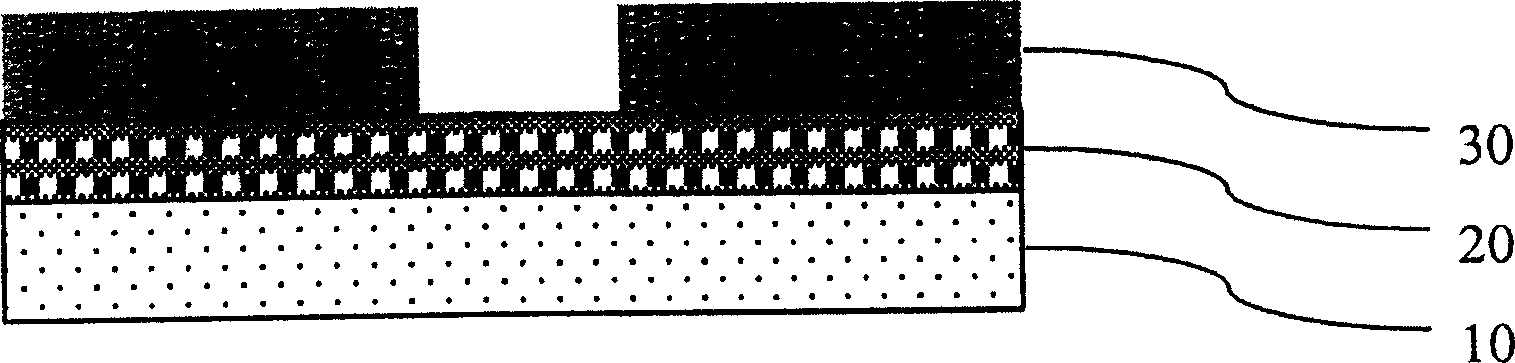

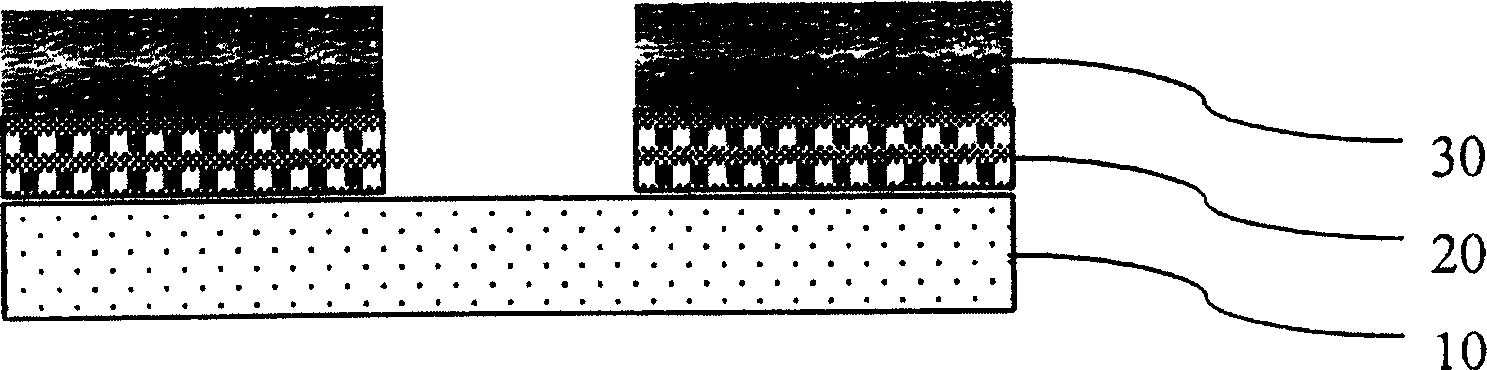

Method used

Image

Examples

Embodiment

[0086] Hereinafter, the present invention will be described in more detail with reference to the following examples, but the present invention is not limited to this

[0087] Examples.

[0088] Under the processing conditions described in Table 2, the substrate was immersed in a stripping solution made of the compounds shown in Table 1, rinsed with deionized water, and then scanned with a scanning electron microscope (SEM) (Hitachi, S-4700) ) Observation results. The evaluation of the peeling ability of the photoresist film and the corrosion resistance of the metal layer and the lower layer is shown in Table 2. The evaluation criteria of SEM are as follows.

[0089] [Peelability]

[0090] ◎: Good

[0091] △: Normal

[0092] ×: Bad

[0093] [Anti-corrosion ability]

[0094] ◎: Good

[0095] △: Normal

[0096] ×: Bad

[0097] Organic Amine

Compound

Glycol ether

Compound

of

Compound

Anti-corrosion agent

Deionize...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap