Method for manufacturing leather fattening agent

A leather fatliquoring agent and technology of manufacturing method, which are applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Application and other issues, to achieve the effect of low organic chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

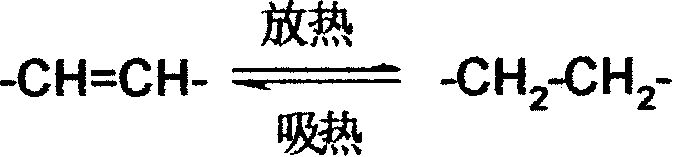

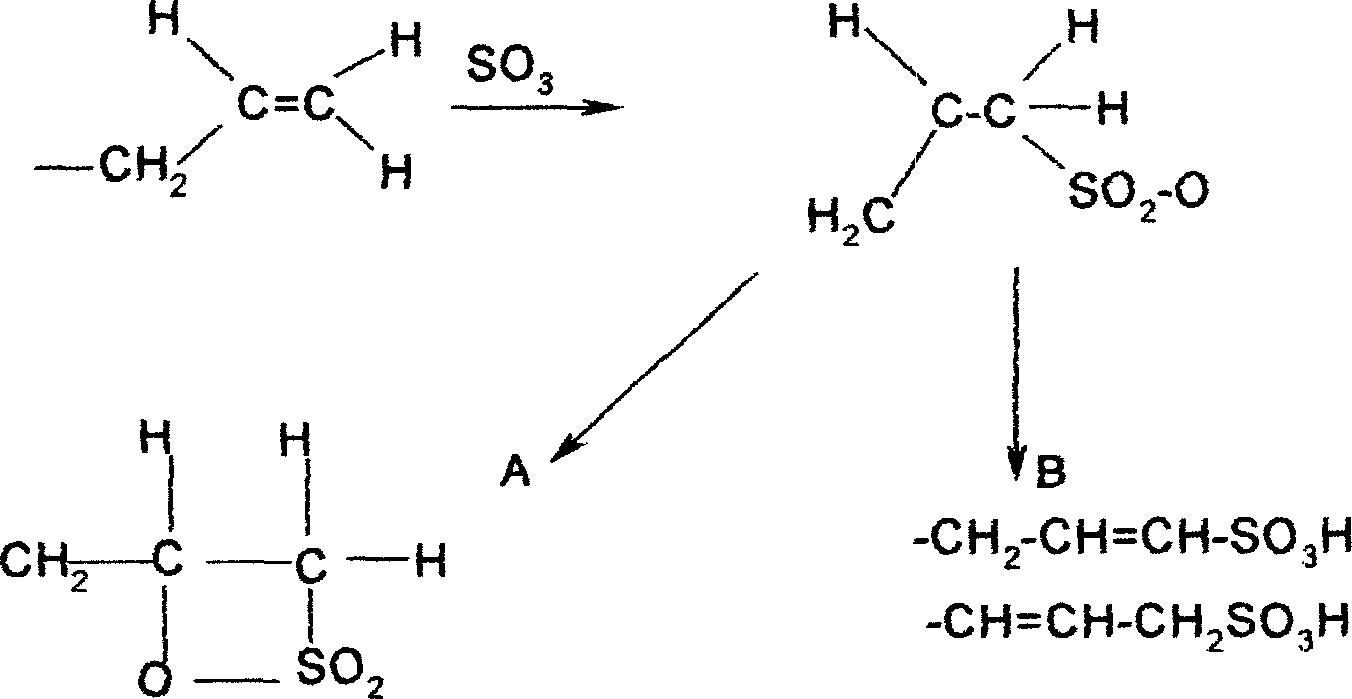

[0031] Preparation of sulfonated mixed oil: use the mixture containing vegetable oil, animal oil and lanolin as raw material, add hydrogen under the action of nickel, copper and other catalysts, the amount of catalyst is 0.05-0.4‰ of the mixture, the hydrogenation condition is that the hydrogen is in In the state of 0.2-0.3Mpa, the mixture is at 150-190°C and in the state of 0.4-0.7Mpa, and the hydrogenation process is carried out in a closed reactor. Finally, after sulfonation treatment, the sulfonated mixed oil is obtained. The sulfonation treatment is through the addition of sulfur trioxide, sulfonation reaction of unsaturated fatty acids (addition reaction of alkenes)

[0032]

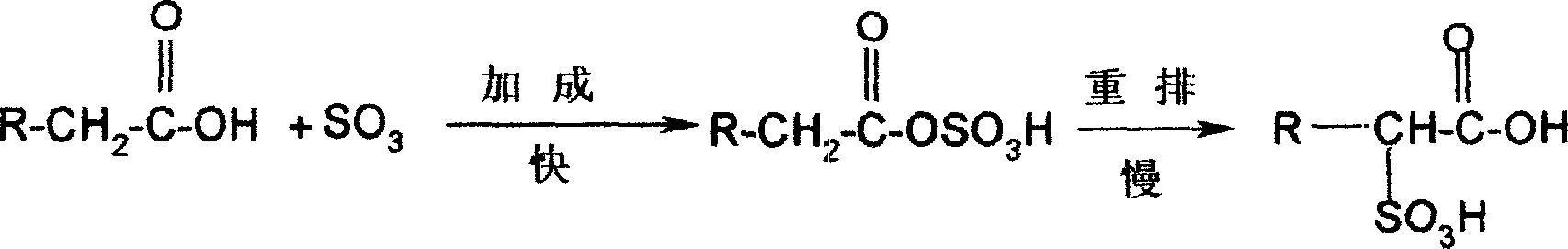

[0033] Sulfonation of saturated long-chain fatty acids or esters:

[0034]

[0035] The reaction equation between esters of saturated fatty acids and sulfur trioxide:

[0036]

[0037]

[0038] hydrogenation time

Iodine value (IV%)

60min

120.6

120min

...

Embodiment 1

[0042] In the 500ml dry there-necked bottle, add to contain the mixture 300g of vegetable oil 150g, animal oil 100g and lanolin 50g (certainly, vegetable oil, animal oil and lanolin can also press containing vegetable oil 50-55%, animal oil 30-35%, lanolin 10- 20% other proportions), put into the reactor 0.2% active ingredient is copper molecular sieve catalyst solid particle, fully stir and mix, be warmed up to 150 ℃ and feed the hydrogen of 0.3MPa pressure, the control stirring speed is 90r / min. At this point, the hydrogenation reaction begins to proceed, and the reaction temperature and hydrogen pressure are adjusted. During the reaction process, the oil is continuously taken out to measure the iodine value, and the reaction is terminated when the iodine value reaches the expected requirement (iodine value IV%3 (SO 3 : air=4.5:95.5, volume ratio) continuous sulfonation to organically bound SO 3 The content is 5.8%, the sulfonation reaction is terminated, and then the pH va...

Embodiment 2

[0044]Add the mixture 300g that contains vegetable oil 150g, animal oil 100g and lanolin 50g in 500ml dry there-necked bottle % other proportions), put into the reactor 0.2% active ingredient is copper molecular sieve catalyst solid particle, fully stir and mix, be warmed up to 150 ℃ and feed the hydrogen of 0.3MPa pressure, the control stirring speed is 90r / min. At this point, the hydrogenation reaction begins to proceed, and the reaction temperature and hydrogen pressure are adjusted. During the reaction process, the oil is constantly taken out to measure the iodine value, and when the iodine value reaches the expected requirement (the iodine value (IV%3 (SO 3 : air=4.5:95.5, volume ratio) continuous sulfonation to organically bound SO 3 The content is 5.8%, the sulfonation reaction is terminated, and then the pH value is adjusted to 6.0 or 7.0 or 8.0 or 7.5 by adding 30% sodium hydroxide to obtain reddish brown transparent sulfonated oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com