Continuous oil sand separating method and apparatus

A separation method, sand-water separation technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of intermittent production process, small device scale and high production cost, and achieve short process, low production cost and less equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

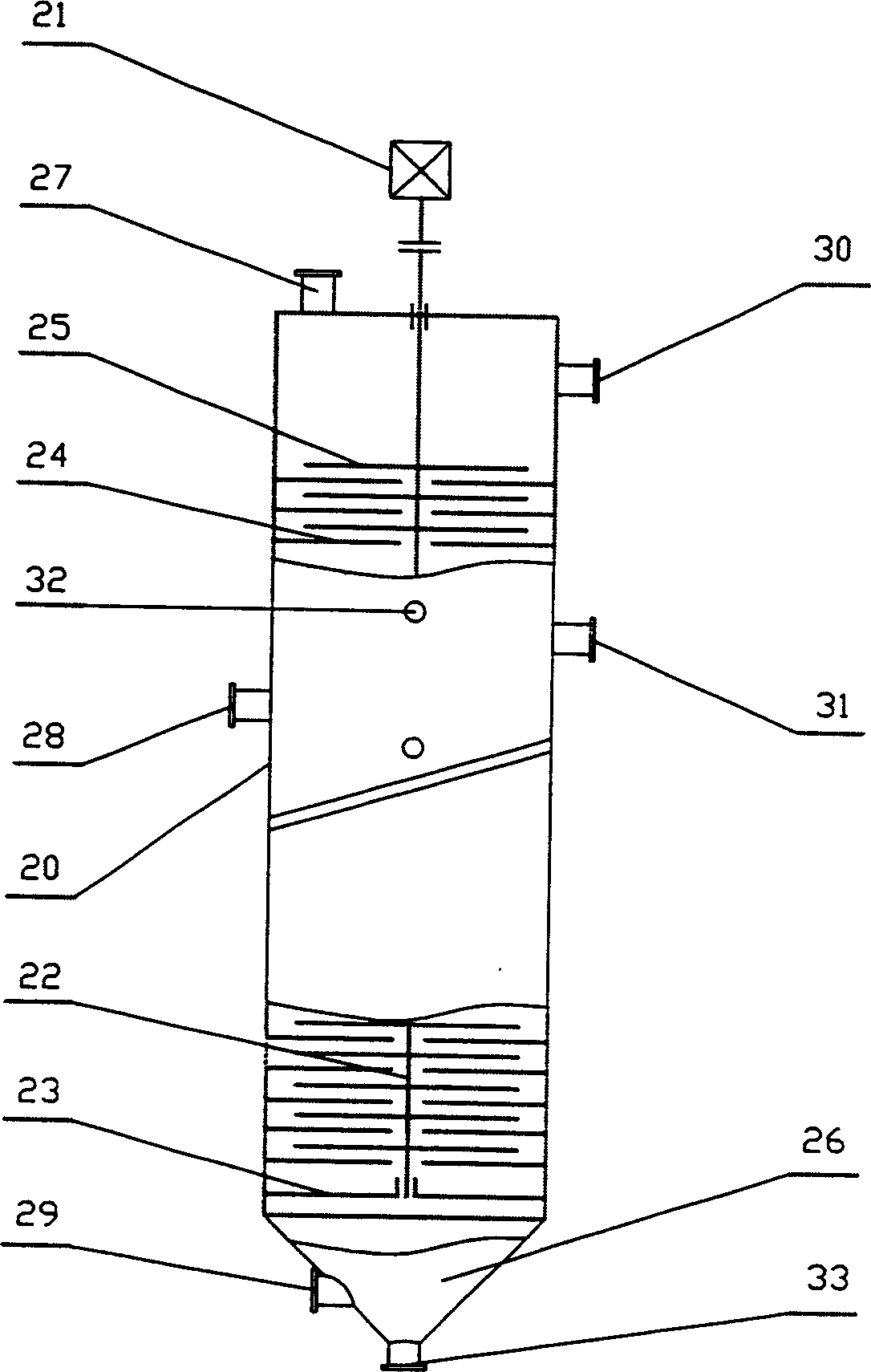

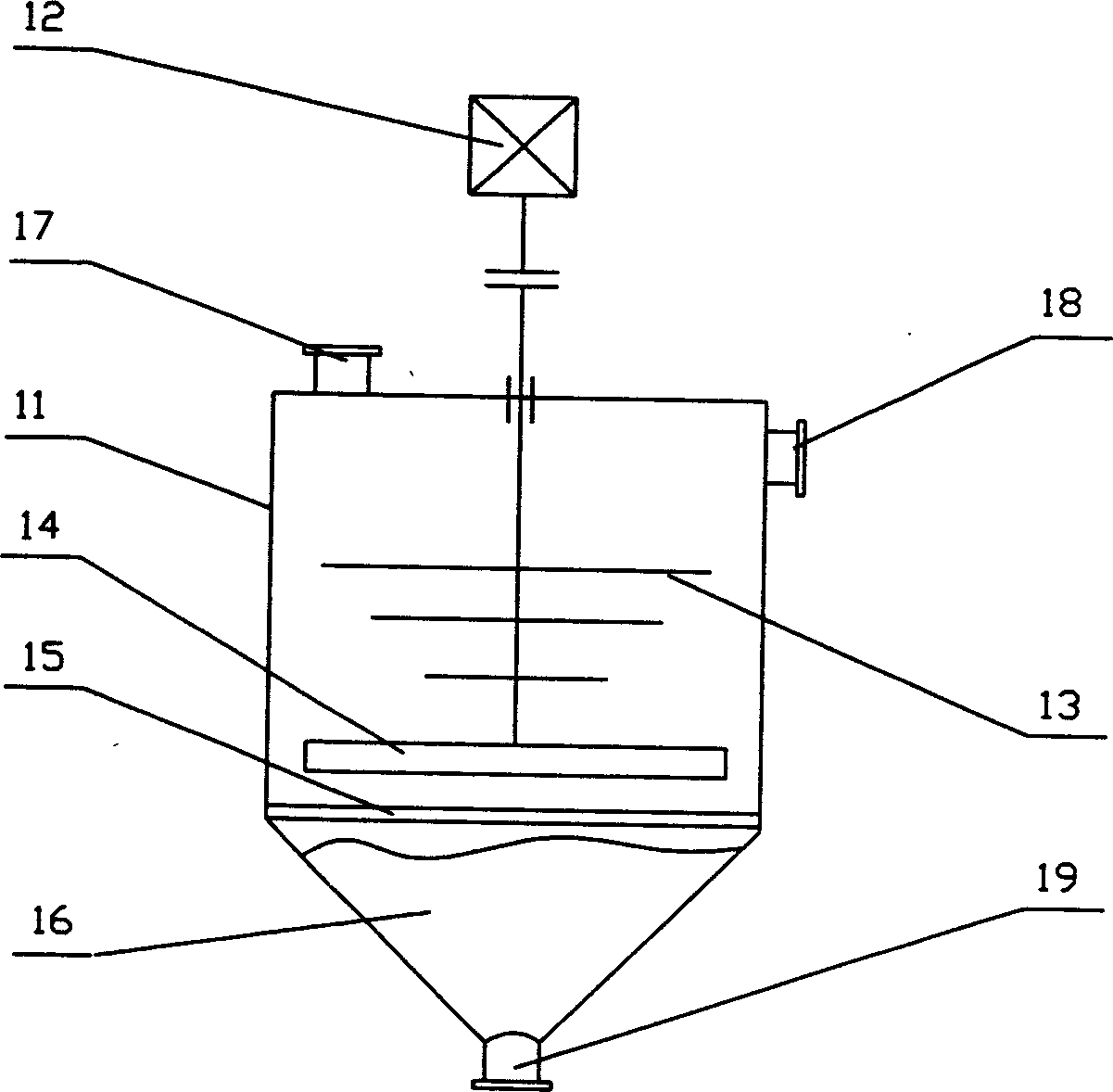

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

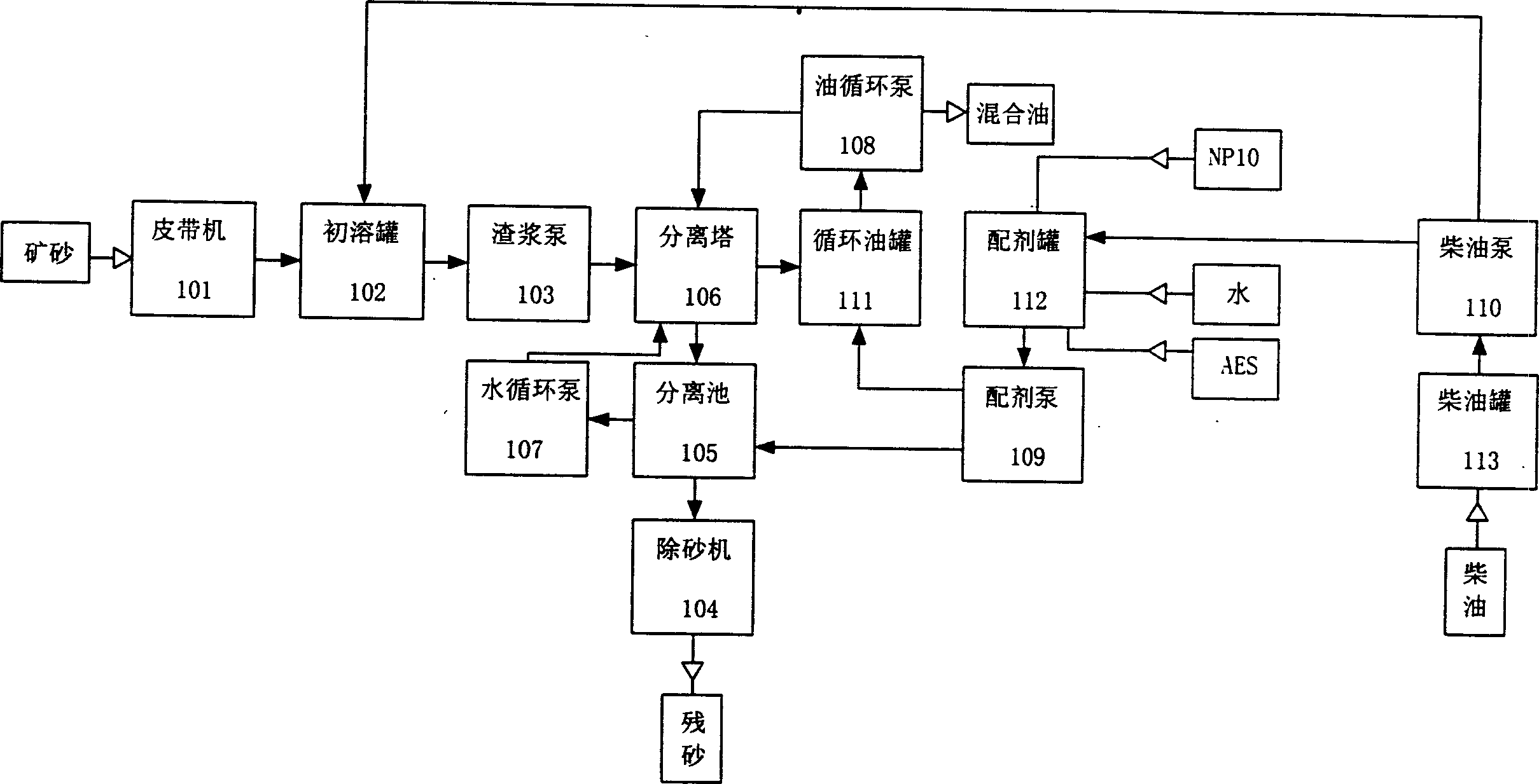

[0022] Such as figure 1 As shown, the process of the continuous oil-sand separation method includes ore lifting and transportation, crushing of ore clusters, ore screening, initial dissolution, oil-sand separation, sand-water separation and auxiliary operation solvent preparation.

[0023] Ore sands are often placed, stored, and transported in the open, and exposed to the atmosphere. The light components of oil in ore sands rarely exist, and basically all of them have a boiling point above 210°C. This is the reason for choosing diesel oil as a solvent; Before the installation, it must go through mineral processing to remove the stones and metal objects entrained in the ore, and make the sand aggregate particle size <50mm;

[0024] The solvent preparation refers to preparation of auxiliary water, preparation of auxiliary diesel oil, mixed liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com