High purity separating and purifying method for naringin, syinaringin, hesperidin and neohesperidin

A technology for separation and purification of neohesperidin, which is applied in the field of separation and purification of active ingredients in traditional Chinese medicine, can solve the problems of irreversible adsorption, environmental pollution, time-consuming and labor-intensive, etc., and achieve large preparation volume, high separation efficiency, and avoid tailing phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

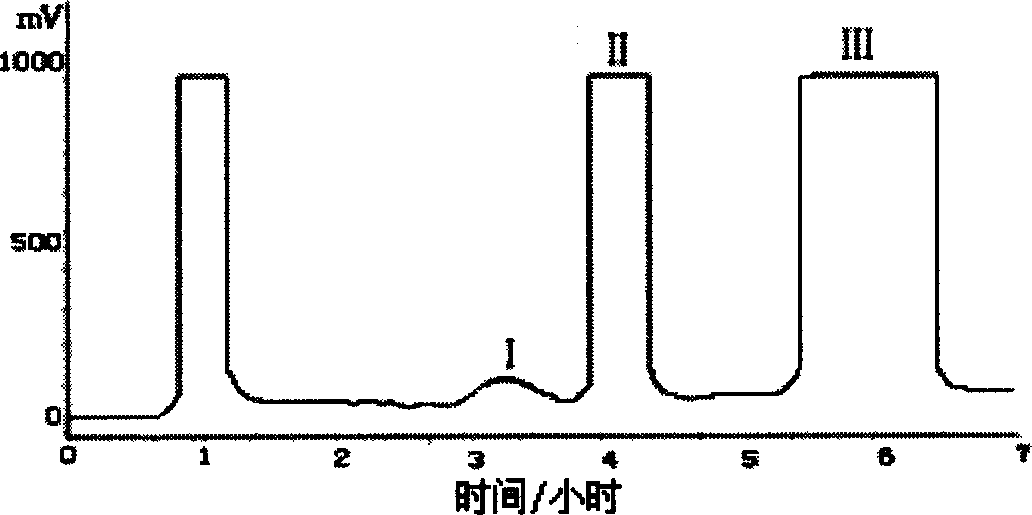

Image

Examples

Embodiment 1

[0026] 1. Weigh 200g of the crude drug of Citrus aurantii, grind it into a coarse powder, put it in a 2000ml round bottom flask, add 1600ml of 60% ethanol, reflux extraction twice, each time for 1.5h, filter, combine the filtrate, and evaporate it under reduced pressure with a rotary evaporator ethanol (temperature 60°C) to obtain a water suspension.

[0027] 2. Take 500g of 905-type macroporous adsorption resin, soak it with 95% medicinal ethanol, make it fully swell, and then change the liquid several times until adding 1ml of ethanol soaking solution to 5ml of water does not show white turbidity. Pack the resin into a column (6.0×70 cm), and rinse the resin with distilled water until there is no alcohol smell.

[0028] 3. Add the water suspension obtained by extracting Fructus Fructus Aurantii to the pretreated chromatographic column, after adsorbing for a period of time, elute with water, 20% ethanol, and 70% ethanol in turn, receive the 70% ethanol eluate, and use Concen...

Embodiment 2

[0046] 1. Weigh 200g of Qingpi crude drug, grind it into a coarse powder, put it in a 2000ml round bottom flask, add 1600ml of 60% ethanol, reflux extraction twice, each time for 1.5h, filter, combine the filtrate, and use a rotary evaporator to evaporate the ethanol under reduced pressure (temperature 60° C.), to obtain extract.

[0047] 2. Take Qingpi extract and add 500ml of water to suspend it, degrease with petroleum ether twice, 500ml each time, separate the water layer, extract with n-butanol 3 times, each time 500ml, recover the n-butanol extract under reduced pressure To the extract, the obtained extract was vacuum-dried to obtain light yellow powder, weighing 15.8g, and the extraction rate was 7.9%.

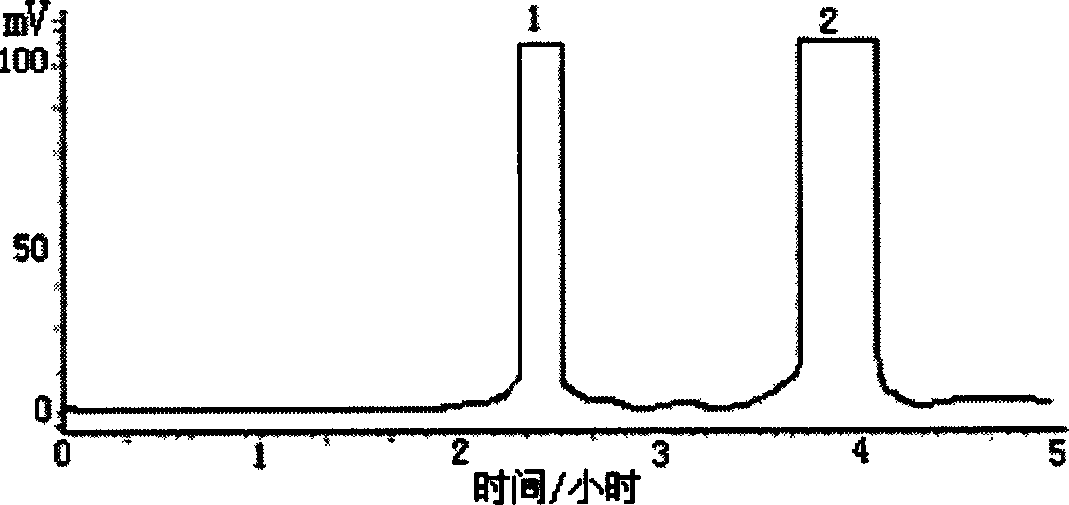

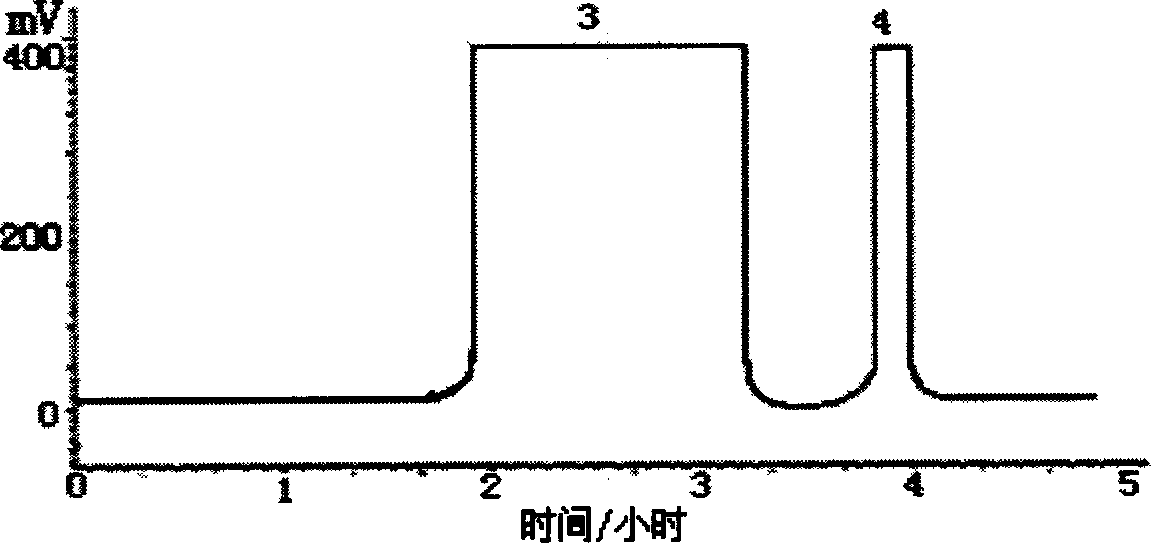

[0048] 3. Use high-speed countercurrent chromatography (Shenzhen Tongtian Biochemical Co., Ltd.) to separate and purify the n-butanol extract of Qingpi.

[0049] The used solvent system and volume ratio of a crude extract separation and separation result are the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com