Method for preparing nano fine particles of cadmium selenide

A nanoparticle, cadmium selenide technology, applied in chemical instruments and methods, binary selenium/tellurium compounds, cadmium compounds, etc., can solve problems such as volatile, affecting the final performance of devices, and explosive, so as to achieve non-volatile, guaranteed Effects of crystal quality and surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

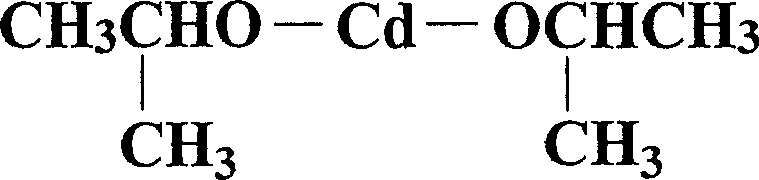

[0024] Preparation of CdSe nanoparticles with cadmium alkoxide as the cadmium source for the reaction:

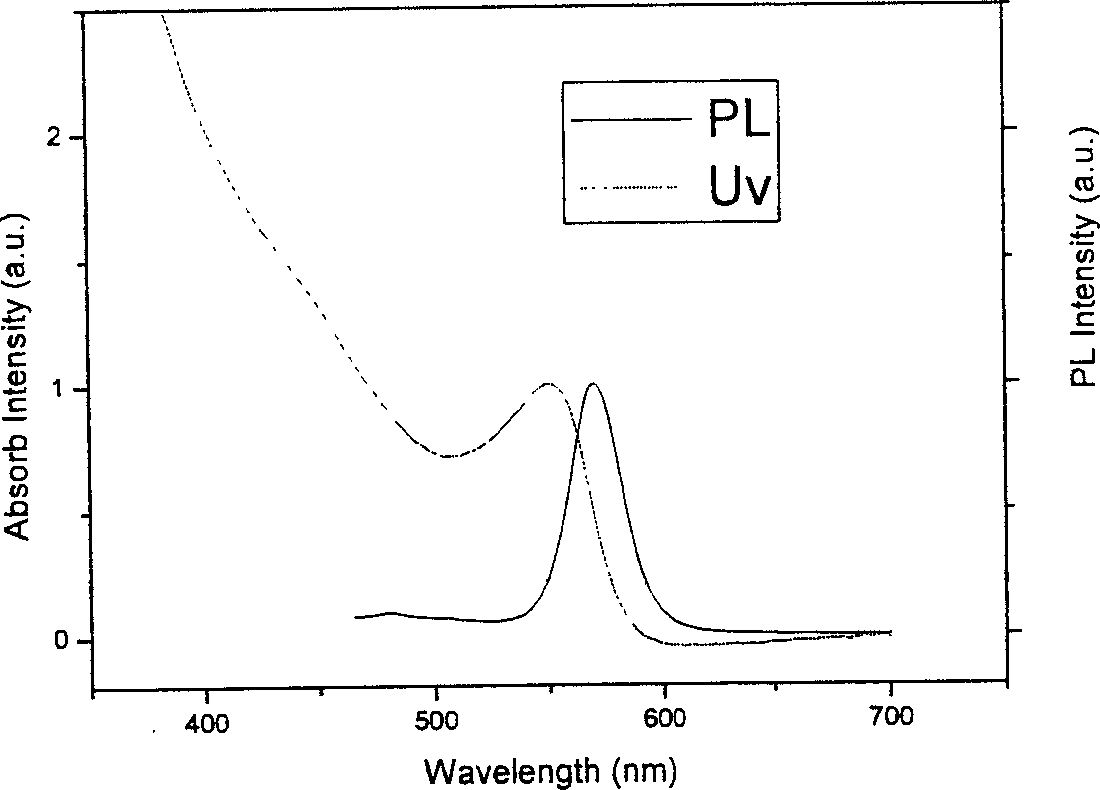

[0025] 200mg of selenium powder was dissolved in 10ml of trioctyl phosphine (TOP) to make precursor mixture I for subsequent use. Mix 50mg of cadmium dimethoxide and 5g of TOPO into the reaction bottle, wash with nitrogen three times, then vacuumize and raise the temperature to 100°C and stir, a slightly yellow and transparent solution can be seen, then raise the temperature to 200°C and keep the temperature for 30 minutes, then stop vacuuming , under nitrogen protection, inject 1ml of precursor mixture I, the molar ratio of cadmium to selenium is 1.1:1, after 20 minutes of reaction, a deep red clear CdSe nanoparticle colloidal solution is generated.

Embodiment 2

[0027] Preparation of CdSe nanoparticles with cadmium alkoxide as the cadmium source for the reaction:

[0028] Mix 50mg of cadmium dimethoxide with 4g of TOPO and 0.5g of hexadecylamine (HDA) into the reaction flask, wash it with nitrogen three times, then vacuumize it and raise the temperature to 100°C for stirring. A slightly yellow and transparent solution can be seen, and then heat up to Keep the temperature at 180°C for 30 minutes, stop vacuuming, protect with nitrogen, inject 1ml of precursor mixture I and react for 20 minutes to generate a bright red and clear CdSe nanoparticle colloid solution.

Embodiment 3

[0030] Preparation of CdSe nanoparticles with cadmium alkoxide as the cadmium source for the reaction:

[0031] Mix 65mg of cadmium diisopropoxide and 4g of TOPO into the reaction bottle, wash with nitrogen three times, vacuumize and heat up to 100°C and stir, a slightly yellow and transparent solution can be seen, then heat up to 200°C and keep the temperature for 30 minutes, stop pumping Vacuum, nitrogen protection, after heating up to 240 ° C constant temperature, inject 1ml of precursor mixture I and react for 20 minutes to generate a dark red CdSe nano particle colloid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com