Composition for paving road and paving body using the same composition

A composition and road technology, which can be applied to coagulating pavements, roads, roads and other directions paved on site, can solve the problems of odor, slow strength, poor construction efficiency, etc., to prevent slippage, improve characteristics, and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0096] Preparation of polyester

[0097] 3500 g of bisphenol A propylene oxide adduct (average added mole number: 2.2 mol), 1160 g of fumaric acid, 0.3 g of hydroquinone, and 8.4 g of dibutyltin oxide were reacted at 160° C. for 4 hours under a nitrogen stream. Then, after raising the temperature to 200° C., the reaction was carried out under normal pressure for 1 hour and under reduced pressure of 9.33 kPa for 1 hour. The obtained polyester had an acid value (AV) of 23.0 mgKOH / g, a hydroxyl value (OHV) of 33.7 mgKOH / g, a softening point (Tm) of 95.1°C, a glass transition point (Tg) of 61.3°C, and a number average molecular weight of 3300 solid. In addition, this polyester is insoluble in water and exhibits hydrophobicity. The softening point is measured using a Koka-type flow rate tester (manufactured by Shimadzu Corporation) under the conditions of a load of 20Kgf (196N), an orifice diameter of 10mm, an orifice length of 1mm, and a temperature rise of 3°C / min. temperature...

preparation example 2

[0099] 2450g bisphenol A propylene oxide adduct (average added moles: 2.2 moles), 950g bisphenol A ethylene oxide adducts (average added moles: 2.1 moles), 830g terephthalic acid, 670 g of dodecenyl succinic anhydride and 11 g of dibutyltin oxide were reacted at 230° C. for 5 hours under a nitrogen stream. Then, after lowering the temperature to 200° C., 480 g of trimellitic anhydride was added, and the reaction was carried out under normal pressure for 1 hour and under reduced pressure of 9.33 kPa for 1 hour. The obtained polyester had an acid value (AV) of 31.7 mgKOH / g, a hydroxyl value (OHV) of 32.5 mgKOH / g, a softening point (Tm) of 104.3°C, a glass transition point (Tg) of 64.0°C, and a number average molecular weight of 3900 solid. In addition, this polyester is insoluble in water and exhibits hydrophobicity.

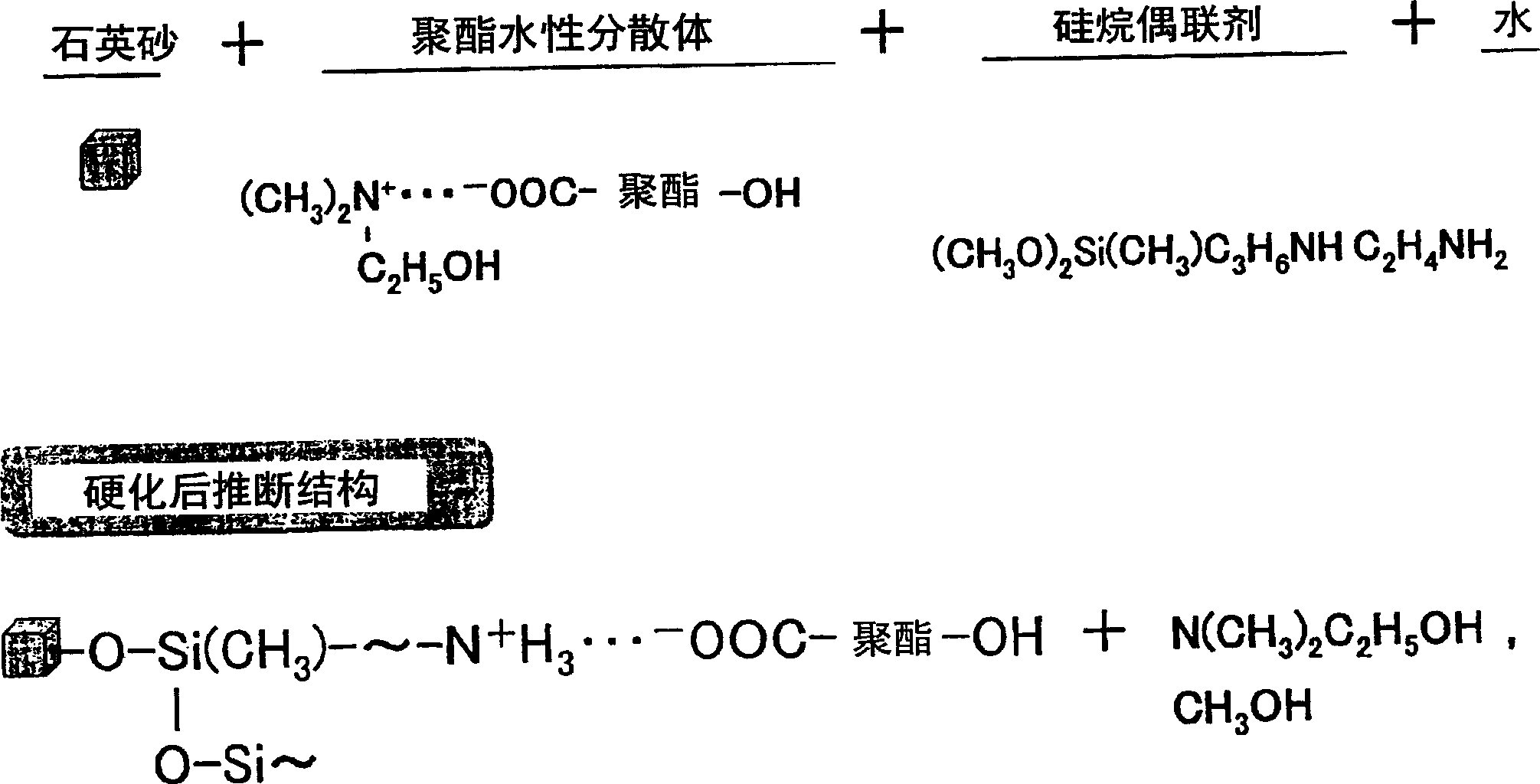

[0100] (1) Preparation of water dispersion (A-1)

[0101] 300 g of polyester obtained in Resin Preparation Example 1 and 45 g of diallyl phthalate were dissolv...

Embodiment 1~4、 comparative example 1~3

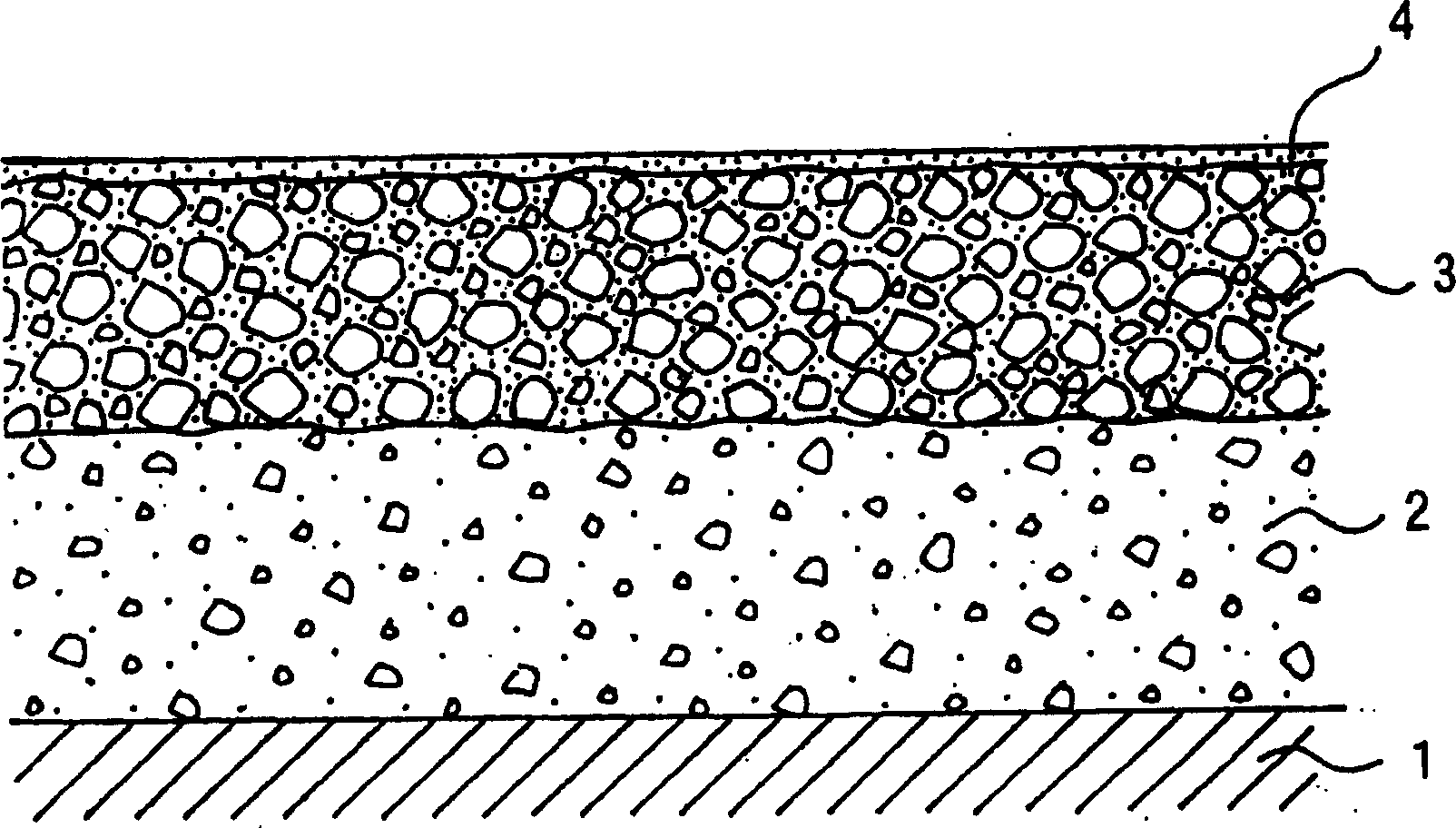

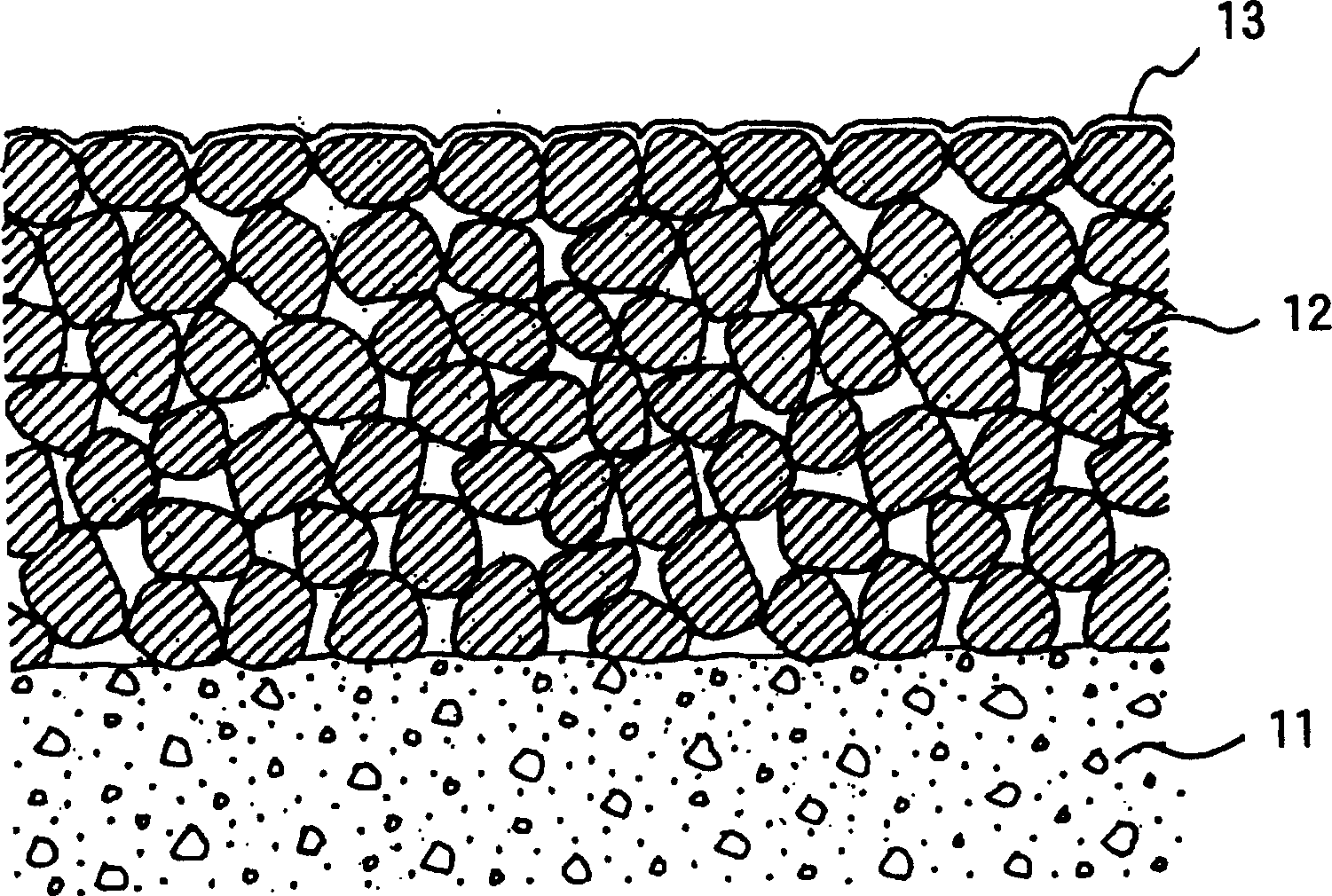

[0105] Next, with the above-mentioned water dispersion (A-1) or water dispersion (A-2) and silane coupling agent as main components, the road paving composition adjusted according to the proportion shown in Table 1 is supplied to the laying On the flattened and rolled asphalt mixture layer, use a rubber rake to lay it flat at 25°C. Coating is carried out twice, and the dosage of each layer is per 1m 2 Use about 1.5Kg. In addition, on the top of the asphalt mixture layer, a surface laid by the currently used room temperature thin layer paving material (ニユ-カラ-コ-ト: manufactured by Toa Road Industry Co., Ltd.) using acrylic latex as a binder is also formed. Floor.

[0106] Ease of construction, hardening time, appearance after coating, abrasion resistance, slip resistance, and water resistance of the surface layer formed above were evaluated, and the results are shown in Table 1.

[0107] For the ease of construction, the case of easy laying and leveling is marked as ○, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com