Technology for producing aluminium oxide

A technology of alumina and new technology, applied in the field of alumina production technology, can solve the problems of too many process links, more cement output, less alumina output, etc., to solve environmental pollution problems, strong market adaptability, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

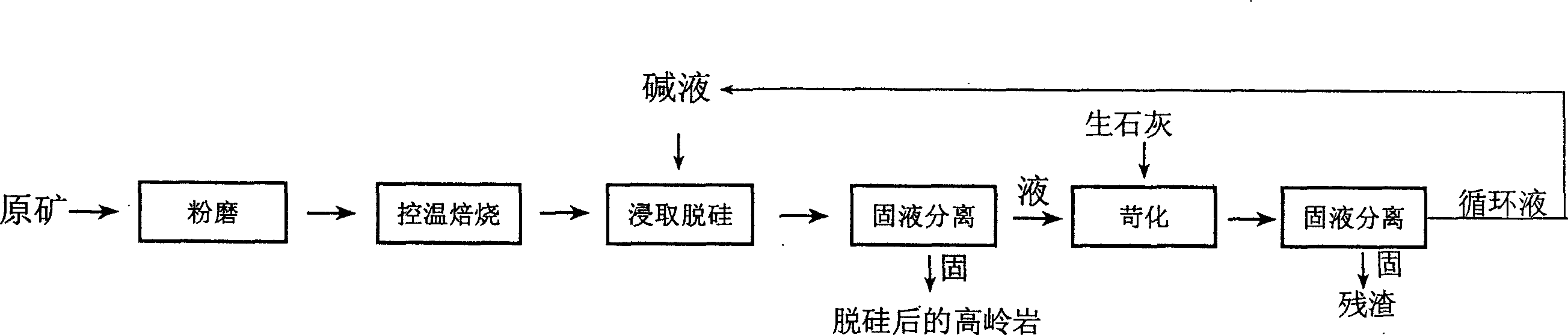

[0010] 1. Kaolin or fly ash desiliconization production process

[0011] The early desiliconization process is attached figure 1 shown. Crush kaolinite to 60-325 mesh, roast at 900°C-1100°C for 1-4 hours (if fly ash is used, no crushing and roasting is required), use 14-18% NaOH lye, add additive water Glass (the addition amount is 1 / 50-1 / 30 of the volume of the desilication alkali solution) or sodium silicate nonahydrate (the addition amount is 5-7g / 150ml), react at 80°C-95°C for 60-90 minutes, that is Complete desiliconization. Wherein: liquid-solid ratio is 4-7ml / g.

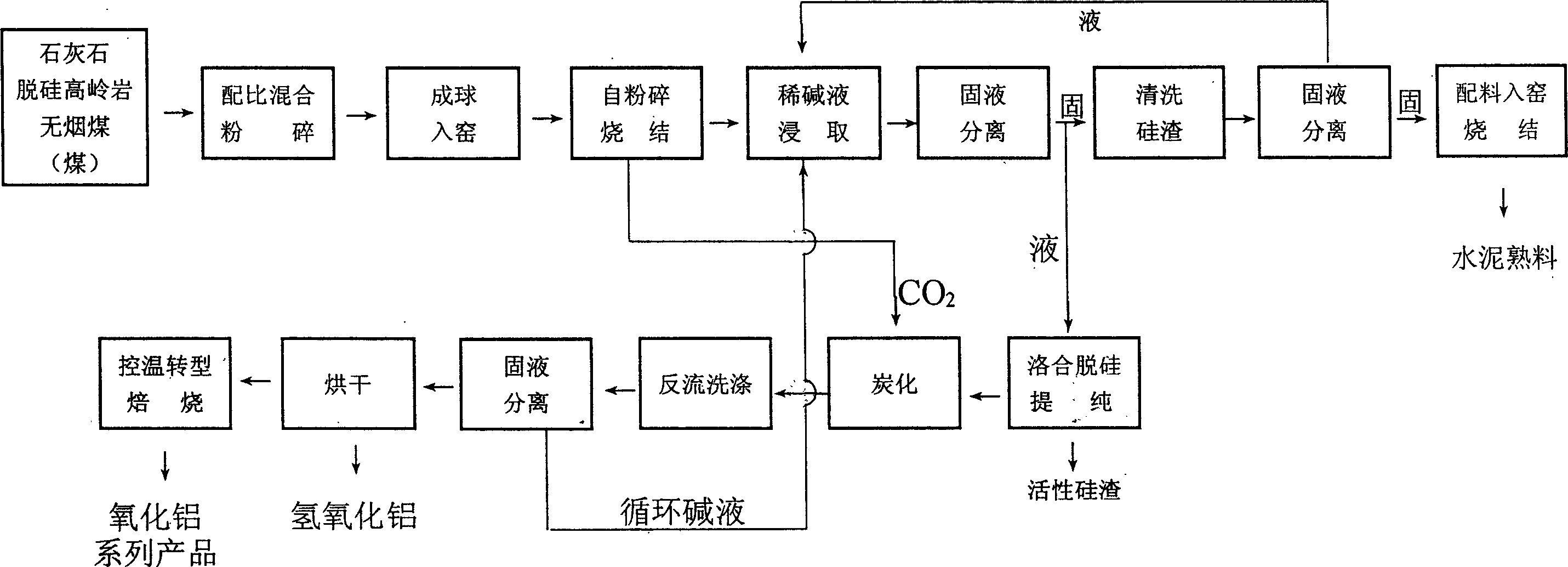

[0012] 2. Alumina production process

[0013] The flow chart of the new process for producing alumina is as follows figure 2 shown. The kaolinite or fly ash that has been desiliconized in advance is mixed with limestone and coal in a certain proportion, crushed to a size of 60-325 mesh, and after being balled, it is fired and roasted in a kiln to form self-crushed clinker powder. The vertical kiln does...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com