High optical efficiency low working voltage cold cathode fluorescent lamp

A cold cathode fluorescent lamp, working voltage technology, applied in the direction of fluorescent, discharge lamp, gas discharge lamp, etc., to achieve the effect of low working voltage, improved luminous efficiency, and prolonged lamp life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

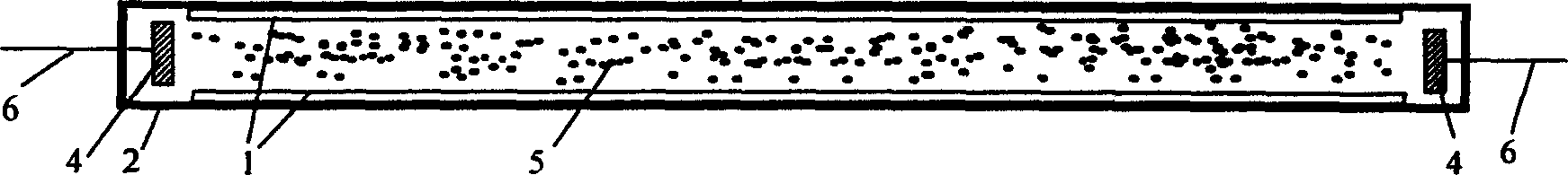

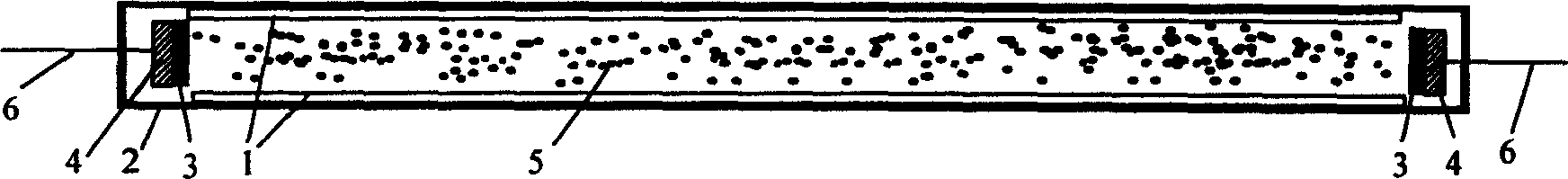

[0013] The cold-cathode fluorescent lamp with high light efficiency and low working voltage of the present invention is to place a pair of metal discharge electrodes whose surface is coated with a medium layer 3 of a material with a high secondary electron emission coefficient at the two ends of the fluorescent lamp glass tube 2 whose inner wall is coated with fluorescent powder 1 4. The discharge electrode 4 is drawn out of the glass tube through the metal lead electrode 6, and the inside of the lamp tube is filled with a discharge gas composed of inert gas helium, or neon, or argon, or xenon, or their mixed gas, and mercury metal. . The dielectric layer 3 made on the surface of the metal discharge electrode 4 is a magnesium oxide or aluminum oxide dielectric layer. Before the metal discharge electrodes of traditional cold cathode fluorescent lamps are sealed and made into tubes, methods such as vacuum coating, or chemical coating, or coating, or impregnation, followed by dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com