Clean production process for spinning by using advanced oxidation method to decompose polyvinyl alcohol pulp of fabric

A technology of advanced oxidation and polyvinyl alcohol, applied in the directions of oxidized water/sewage treatment, light water/sewage treatment, etc., can solve the problems of poor biodegradability of wastewater, and achieve complete oxidation of products, no secondary pollution, and no pollution to the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

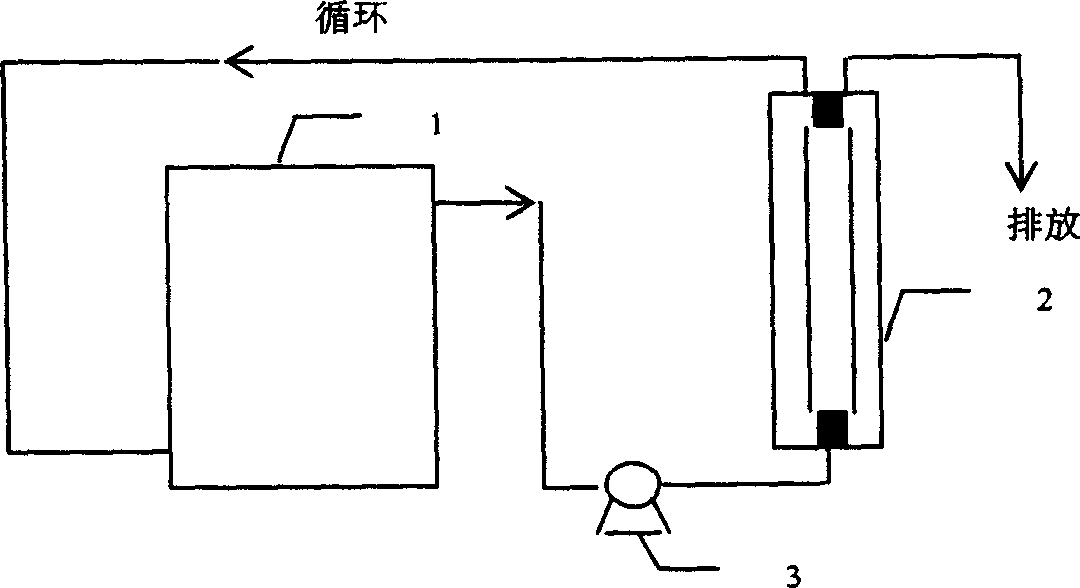

Method used

Image

Examples

preparation example Construction

[0029] 2. Preparation of laboratory sizing polyester-cotton fabric sample

[0030] Cut the unsized polyester-cotton fabric into 5×5cm 2 Then, soak in 20g / L PVA solution for 15min and bake at 105℃ for 30min. Repeat the operation 3 times.

[0031] 3. Preparation of sizing polyester-cotton fabric in desizing tank of textile mill and sampling of desizing wastewater

[0032] Cut the polyester-cotton fabric sizing in the desizing tank to 5×5cm 2 Then take 400ml of desizing wastewater from the desizing tank, then mix the two to continue desizing for 1 hour, and then enter the advanced oxidation reactor.

[0033] 4. Desizing operation parameters

[0034] The initial concentration of polyvinyl alcohol in the desizing wastewater is less than 2000mg / L. After the desizing wastewater is pumped into the advanced oxidation reactor, hydrogen peroxide is added dropwise to it so that the initial concentration of hydrogen peroxide is 100~1000mg / L, and the oxidation time is 2 to 3 hours.

Embodiment 1

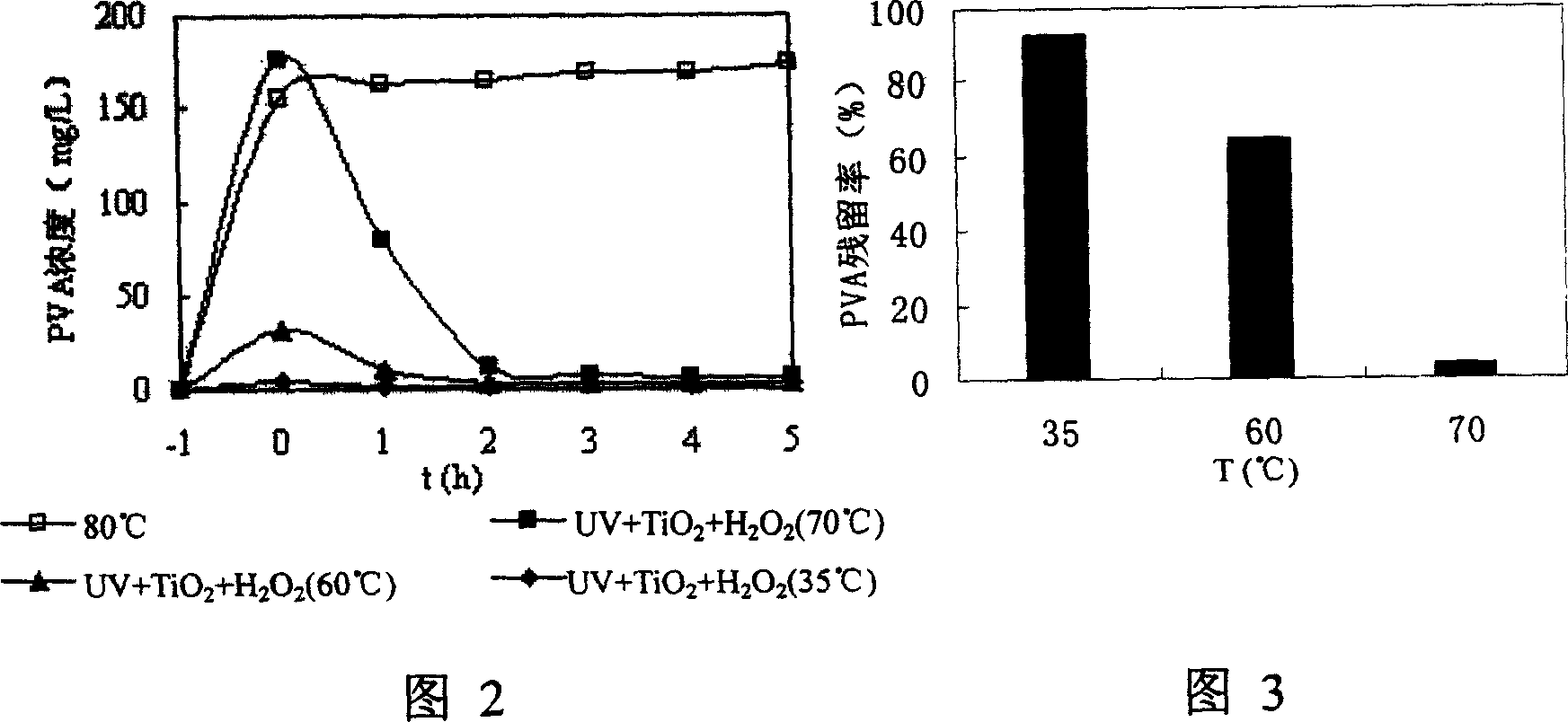

[0036] Desizing treatment with a sample of sizing polyester / cotton fabric in the laboratory, and inspected UV+TiO 2 +H 2 O 2 Advanced oxidation reaction system removes the PVA effect on polyester-cotton fabrics. In the advanced oxidation reactor, H is added dropwise to the desizing wastewater 2 O 2 , Make H 2 O 2 The initial concentration is 100mg / L, and then put the ultraviolet lamp in the quartz tube coated with titanium dioxide layer, irradiate the desizing wastewater for oxidation treatment, and conduct parallel tests at different temperatures of 35℃, 60℃ and 70℃, and 80℃ The desizing wastewater without advanced oxidation treatment after desizing treatment was used as a control. The test results are shown in Figure 2 and Figure 3. After treatment, the final concentration of PVA in the desizing wastewater is close to zero, and the residual rate of PVA on the polyester-cotton fabric at 70°C is below 10%.

Embodiment 2

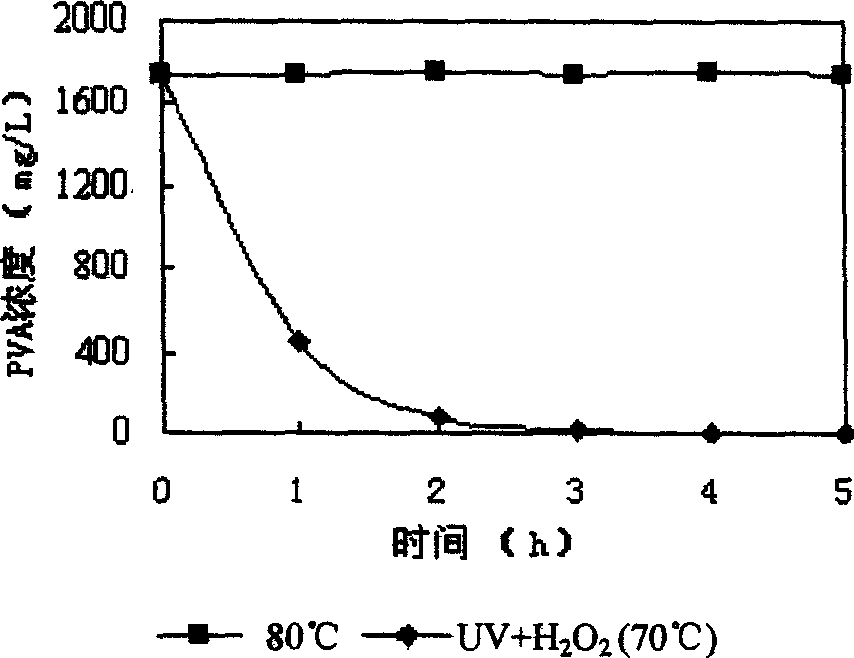

[0038]Take the medium-sized polyester-cotton fabric in the textile factory as a sample and mix the sampled desizing wastewater for desizing treatment, and inspect the UV+H 2 O 2 The advanced oxidation reaction system removes the PVA effect on polyester-cotton fabrics. In the advanced oxidation reactor, H is added dropwise to the desizing wastewater 2 O 2 , Make H 2 O 2 The initial concentration is 1000mg / L, and then put the ultraviolet lamp in the quartz tube, irradiate the desizing wastewater for oxidation treatment, and conduct the test at 70°C. In addition, use the desizing wastewater that has not undergone advanced oxidation treatment after desizing treatment at 80°C. Control, the test results are as Figure 4 , Figure 5 Shown. After treatment, the final concentration of PVA in the desizing wastewater is close to zero, and the residual rate of PVA on the polyester-cotton fabric is below 10% at 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com