Semiconductor device and manufacturing method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their manufacturing, can solve the problems of increased chip cost, inability to obtain sufficient di/dt capability, difficulties, etc., and achieve the effect of low forward voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, preferred embodiments of a semiconductor device and a method of manufacturing the same according to the present invention will be explained in detail with reference to the accompanying drawings.

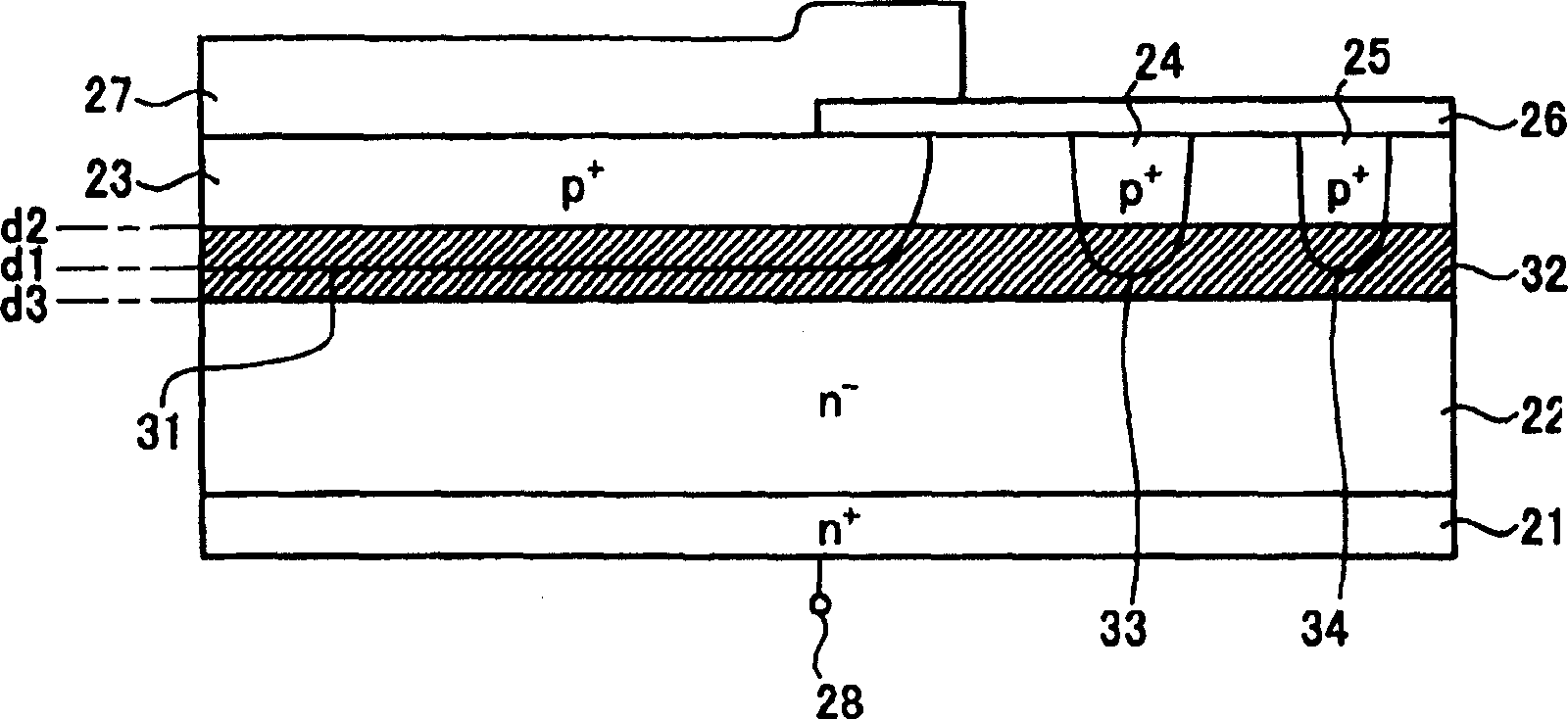

[0040] figure 1 is a cross-sectional view showing a planar PIN diode structure according to one embodiment of the present invention. like figure 1 As shown in n + On the semiconductor layer 21, the n that is the cathode region is set - semiconductor layer 22 . As the diode is in the active region allowing current to flow, the n - On the surface layer of the semiconductor layer 22, an anode region p + Diffusion zone 23.

[0041] Also, in the voltage withstand structure portion on the outside of the active region, in n - On the surface layer of the semiconductor layer 22, p + Diffusion zones 24 and 25. The surface of the voltage-resistant structure is covered with SiO 2 The insulating film 26 of the film. p + The diffusion layer 23 is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com