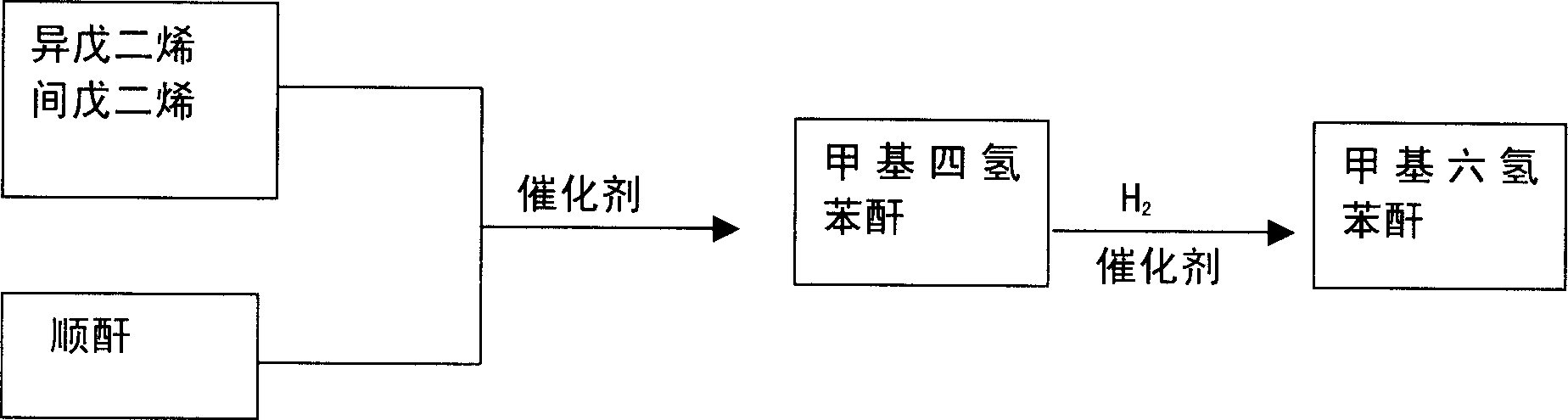

Novel method for producing methyl hexahydrobenzene anhydride

A technology of methyl hexahydrophthalic anhydride and methyl tetrahydrophthalic anhydride, applied in the new field of producing methyl hexahydrophthalic anhydride, can solve problems such as easy coking, high boiling point, catalyst poisoning, etc. The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

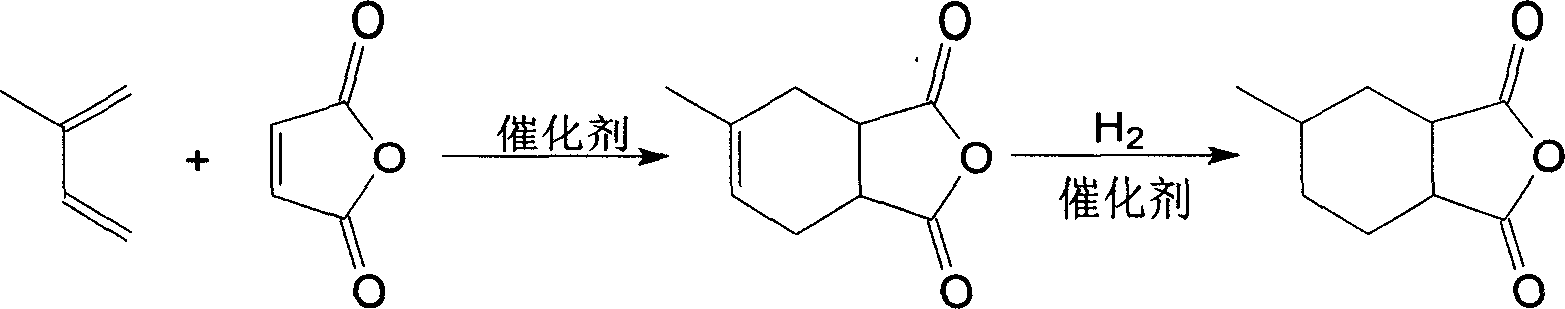

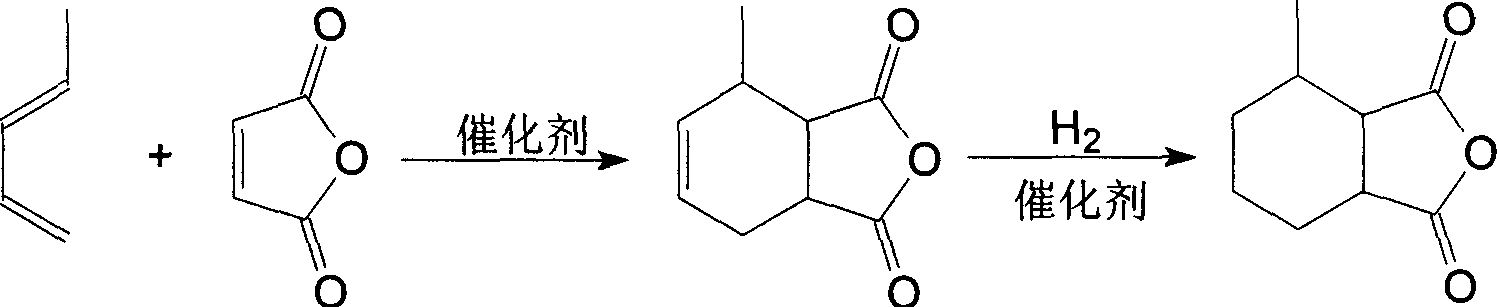

Method used

Image

Examples

Embodiment 1

[0022] At a temperature of 50°C and in the presence of 3 grams of aluminum chloride, gradually add decyclized carbon five (its main components are isoprene and piperylene) to 98 grams of maleic anhydride, through the Diels-Alder reaction Methyltetrahydrophthalic anhydride is produced. Then add 1 gram of skeleton nickel and 0.1 gram of bis(bis-diphenylphosphinoxyethane) copper tetrabromide polymer to the generated methyltetrahydrophthalic anhydride, in an autoclave at a temperature of 140° C. and a hydrogen pressure of 4 MPa The catalytic hydrogenation reaction was carried out for 4 hours, the catalyst was filtered after cooling, and 152 g of colorless liquid methyl hexahydrophthalic anhydride was obtained by distillation under reduced pressure, with a yield of 90.3%.

Embodiment 2

[0024] At a temperature of 80°C and in the presence of 1.5 grams of aluminum chloride, gradually add decyclized carbon five (its main components are isoprene and piperylene) to 98 grams of maleic anhydride to react to generate methyltetrahydrophthalic anhydride. Then add 2.5 grams of skeleton nickel and 0.3 grams of bis(bis-diphenylphosphinoxyethane) copper tetrabromide polymer to the generated methyltetrahydrophthalic anhydride, in an autoclave with a temperature of 120 ° C and a hydrogen pressure of 2 MPa The catalytic hydrogenation reaction was carried out for 5 hours, the catalyst was filtered after cooling, and 157 g of colorless liquid methyl hexahydrophthalic anhydride was obtained by distillation under reduced pressure, with a yield of 93.3%.

Embodiment 3

[0026] In the presence of a temperature of 120° C. and 0.5 g of zinc chloride, gradually add decyclized C5 (its main components are isoprene and piperylene) to 98 g of maleic anhydride to react to generate methyltetrahydrophthalic anhydride. Then add 5 grams of skeleton nickel and 0.5 grams of bis(bis-diphenylphosphinoxyethane) copper tetrabromide polymer to the generated methyltetrahydrophthalic anhydride, in an autoclave with a temperature of 100 ° C and a hydrogen pressure of 1 MPa The catalytic hydrogenation reaction was carried out for 6 hours, the catalyst was filtered after cooling, and 155 g of colorless liquid methyl hexahydrophthalic anhydride was obtained by distillation under reduced pressure, with a yield of 92.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com