High dielectric constant polyimide/ceramic complex film and its preparation method

A technology of ceramic composite film and high dielectric constant, which is applied in the field of high dielectric constant polyimide/ceramic composite film and its preparation, can solve the problem that the temperature resistance, chemical corrosion resistance strength and flexibility of the composite film cannot fully meet the use requirements , It is not easy to control the thickness of the composite film, the flatness and adhesion, the uniformity of the ceramic powder dispersion structure, etc., to achieve the effects of good chemical stability, high power, and strong heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1) Modification of ceramic powder A1: Add 50g of A1 (A105) with an average particle size of 0.5μm into 200ml of absolute ethanol at room temperature, turn on ultrasound and stirring; add 1.25g of 3-aminopropyltriethoxysilane (APTES, U.S. Dow Corning Company, model: Z-6011) was heated to 65-70°C and stirred for 2 hours; then 10ml of deionized water was added and stirred for 2 hours; the powder was separated by filtration, washed with absolute ethanol three times, and vacuum After drying for 20 hours, it was sealed to obtain modified A1 (A105A), which was sealed and placed in a desiccator for later use.

[0069] 2) Preparation of PMDA / ODA PI / A105A non-crosslinked composite film by in-situ polymerization: 10g A105A and 5.214g (23.91mmol) pyromellitic dianhydride (PMDA, Shanghai Sanwei Industrial Co., Ltd.) monomer was added to 70ml In anhydrous N,N'-dimethylacetamide (DMAC), stir in an ultrasonic field at a temperature of 20-50°C for 2 hours, PMDA dissolves; cool the suspe...

Embodiment 2

[0074] (1) Modification of porcelain powder A1: A105 was replaced by A1 (A120) with an average particle size of 2.0 μm, and APTES modified A1 (A120A) was obtained according to the same operation as in Example 1 (1).

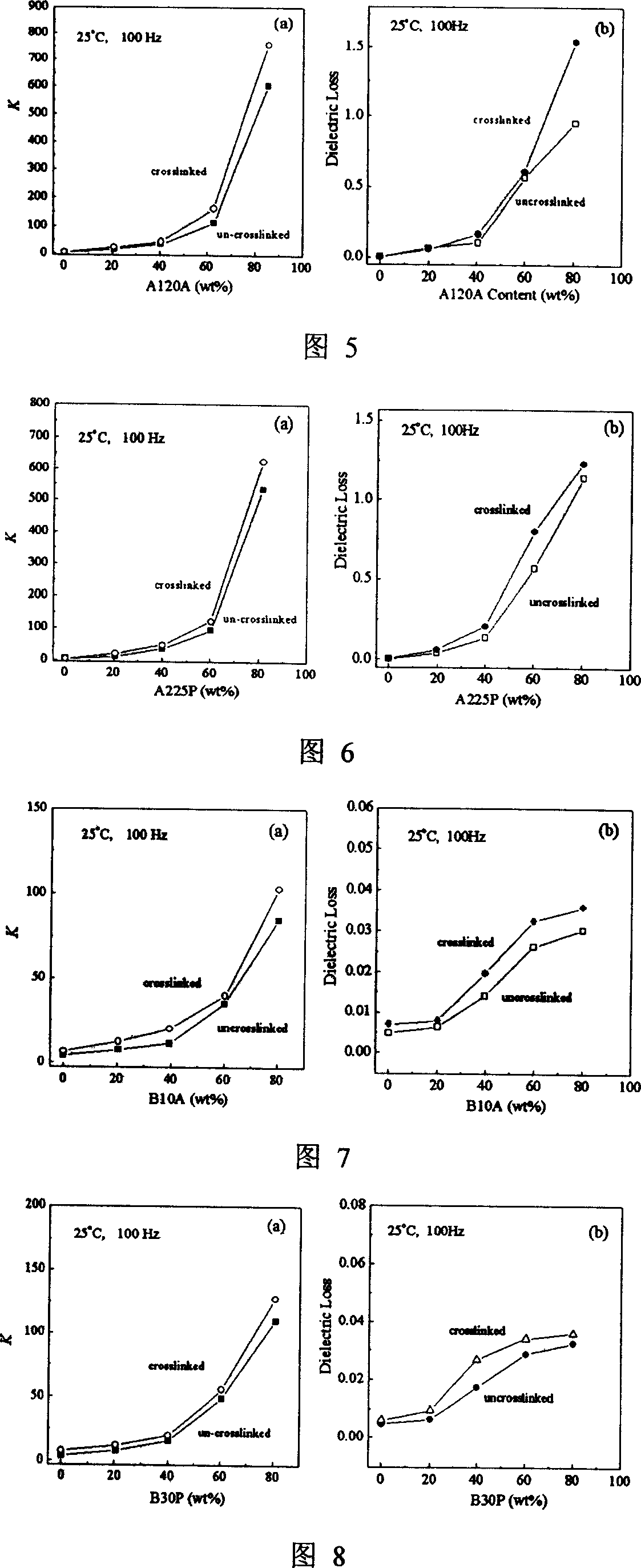

[0075] (2) In-situ polymerization method prepares PMDA / ODA class PI / A120A composite film: replace A105A with A120A, adopt and example 1 (2), (3) in identical operation, obtain PMDA / ODA class PI / A120A joint composite film , its electrical properties are shown in Figure 5.

Embodiment 3

[0077] (1) Modification of ceramic powder A2: replace A105, γ-(2,3 glycidoxy) propyltriethoxysilane (POTES, American Union Carbide) with A2 (A225) with an average particle size of 2.5.μm Company, model: A-187) instead of APTES, according to the same operation as in Example 1 (1), to obtain A2 (A225P) with POTES modification and an average particle size of 2.5 μm.

[0078] (2) Preparation of BTDA / ODA-like PI / A225P composite film by in-situ polymerization: replace A105A with A225P, and use 3,3',4,4'-benzophenone tetraacid dianhydride (BTDA, Beijing Gas Coal Chemical Research Institute ) instead of PMDA, the same operation as in Example 1 (2) and (3) was used to obtain BTDA / ODA-like PI / A225P composite film, the electrical properties of which are shown in Figure 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com