Method for preparing nano-titanium oxide/amide derivative electrorheological fluid

A technology of amide derivatives and electrorheological fluids, applied in chemical instruments and methods, mixing methods, lubricating compositions, etc., can solve problems that hinder the wide application of electrorheological fluids, poor anti-sedimentation, narrow working temperature range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

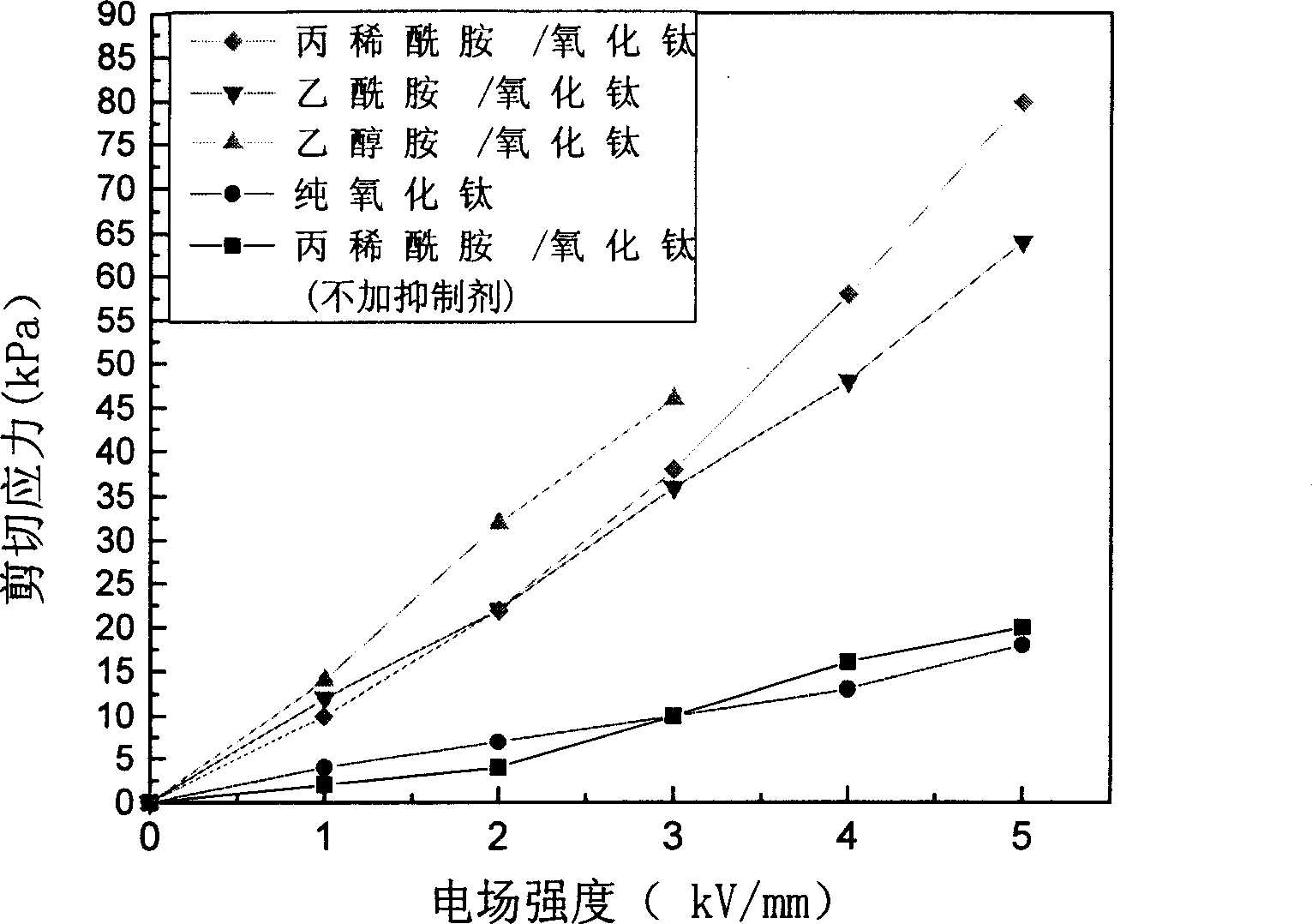

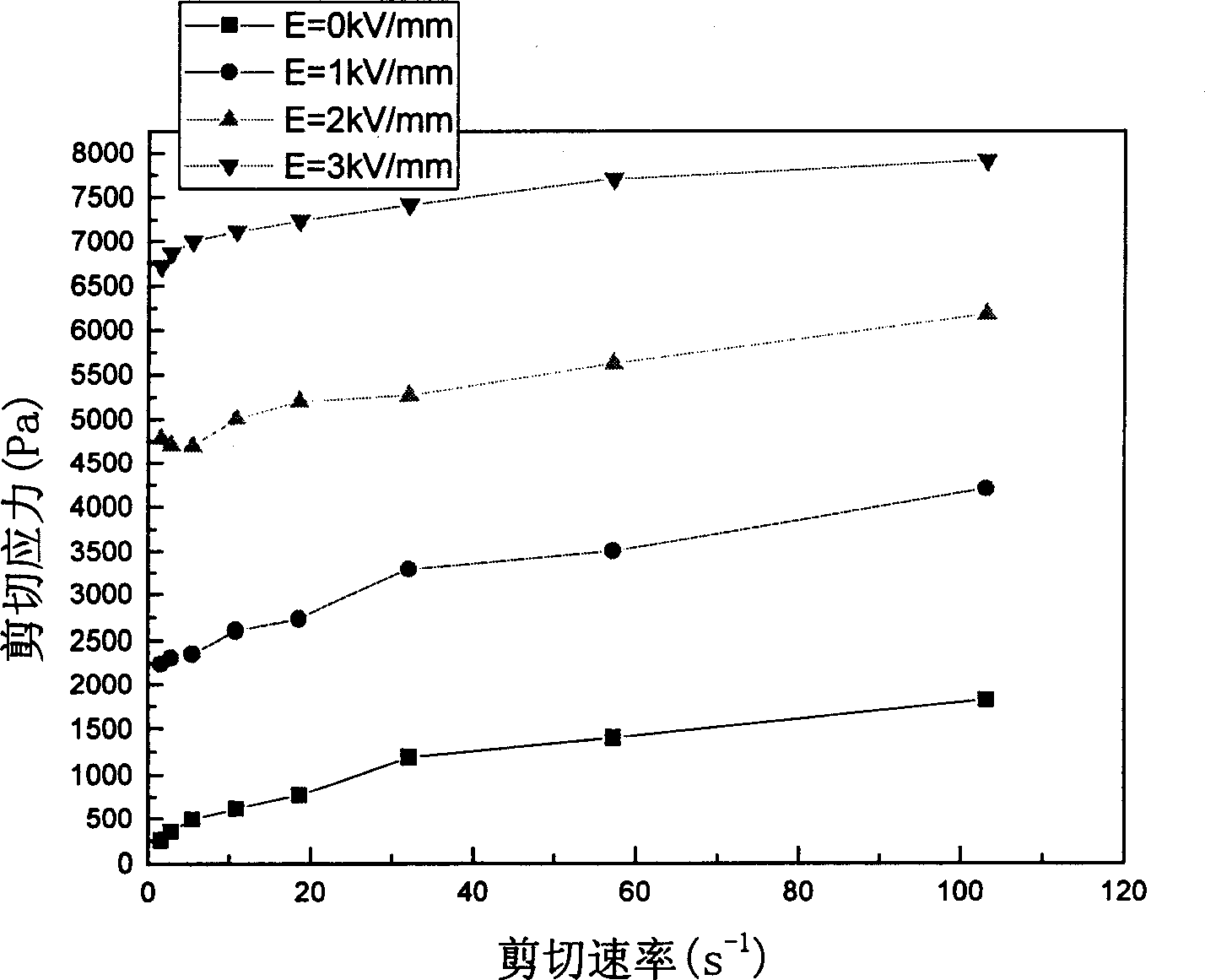

[0014] Example 1: (Titanium Oxide / Acrylamide Nano Electrorheological Fluid)

[0015] First, add 15ml of tetrabutyl titanate and 2ml of glacial acetic acid into 250ml of absolute ethanol, stir for 3 hours, and make solution A; meanwhile, add 6g (1.5% by weight) of sodium lauryl sulfate, 5g Add acrylamide to 400ml of deionized water, stir for 3 hours to make solution B; then slowly drop solution A into solution B under strong stirring, and then add 0.5ml glacial acetic acid dropwise to adjust The pH value of the solution is 3.5, continue to stir for two days, let the particles settle, and then use a vacuum filter to dry them; then vacuum-dry the filter cake at 70°C for 4 hours, take it out and grind it into a powder, and then put it in a drying oven Let dry for 3 hours. Then carefully grind for 5 hours until it is relatively smooth to get the sample powder. Add the sample powder into 1ml of methyl silicone oil in batches, and after each powder addition, it must be fully ground...

Embodiment 2

[0016] Example 2: (Titanium Oxide / Acetamide Nano Electrorheological Fluid)

[0017] First, add 15ml of tetrabutyl titanate and 2ml of glacial acetic acid into 250ml of absolute ethanol, stir for 3 hours, and make solution A; meanwhile, add 6g (1.5% by weight) of sodium lauryl sulfate, 5g Add acetamide to 400ml of deionized water, stir for 3 hours to make solution B; then slowly drop solution A into solution B under strong stirring, and then add 0.5ml glacial acetic acid to adjust the solution The pH value is 3.5, continue to stir for two days, let the particles settle, and then dry them with a vacuum filter; then vacuum-dry the filter cake at 70°C for 4 hours, take it out and grind it into powder, and then dry it in a drying oven 3 hours. Then carefully grind for 5 hours until it is relatively smooth to get the sample powder. Add the sample powder into 1ml of methyl silicone oil in batches, grind it thoroughly after each powder addition to fully infiltrate the powder and oil...

Embodiment 3

[0018] Embodiment three: (pure titanium oxide electrorheological fluid)

[0019] First, 15ml of tetrabutyl titanate and 2ml of glacial acetic acid were added to 250ml of absolute ethanol, and stirred for 3 hours to form a solution A; at the same time, 6g (1.5% by weight) of sodium lauryl sulfate was added to the 400ml of deionized water, stirred for 3 hours to make solution B; then slowly drop solution A into solution B under strong stirring, and then add 0.5ml glacial acetic acid dropwise to adjust the pH value of the solution to 3.5 , continue to stir for two days, let the particles settle, and then dry them with a vacuum filter; then vacuum-dry the filter cake at 70°C for 4 hours, take it out and grind it into powder, then dry it in a drying oven for 3 hours, and then carefully Grind for 5 hours until it is relatively smooth to get the sample powder. Add the sample powder into 1ml of methyl silicone oil in batches, grind it thoroughly after each powder addition to fully in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com