Powder film spraying machine

A powder and film spraying technology, applied in liquid spraying equipment and other directions, can solve the problems of low efficiency, easy heating, low load capacity, etc., and achieve the effect of improving deposition effect, reducing pollution and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

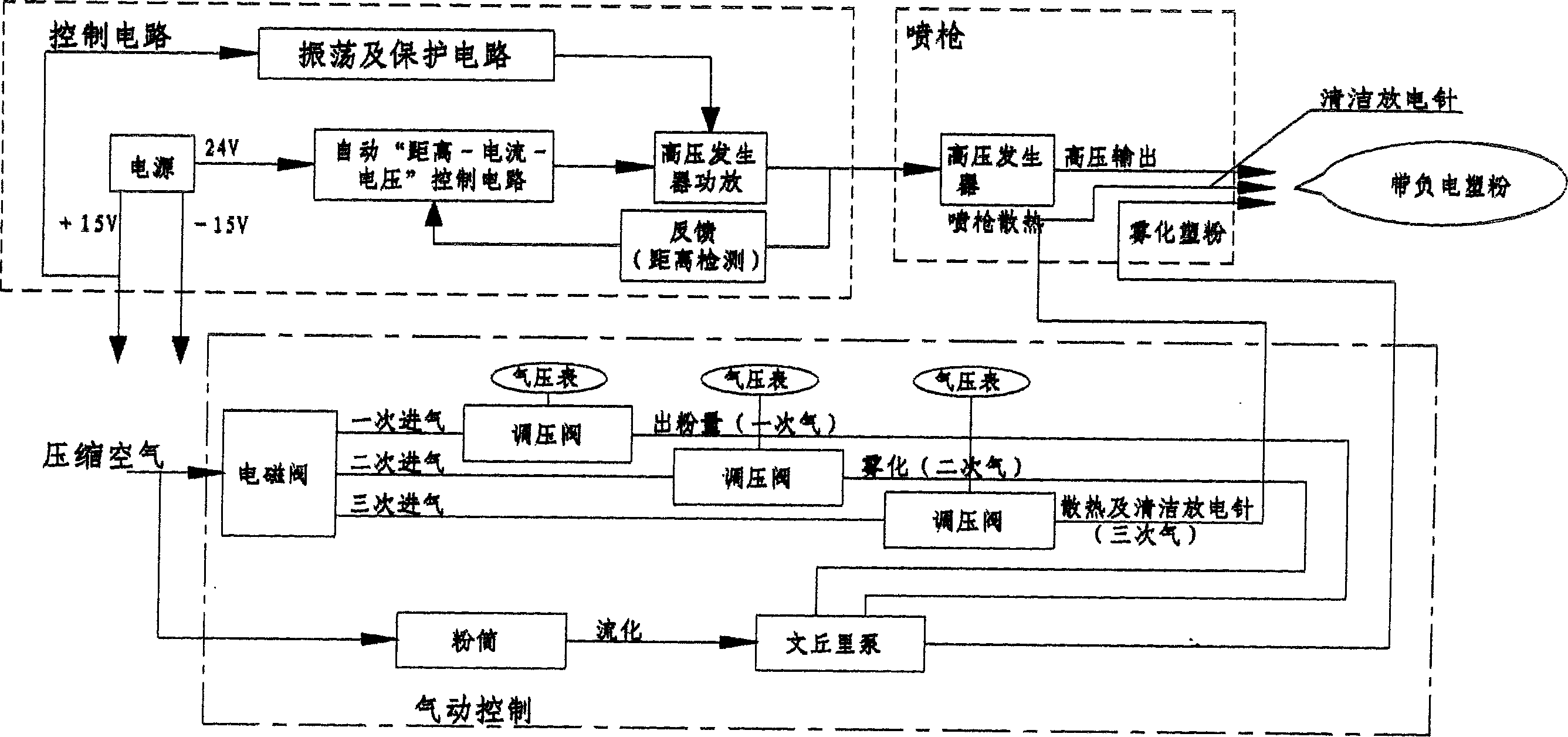

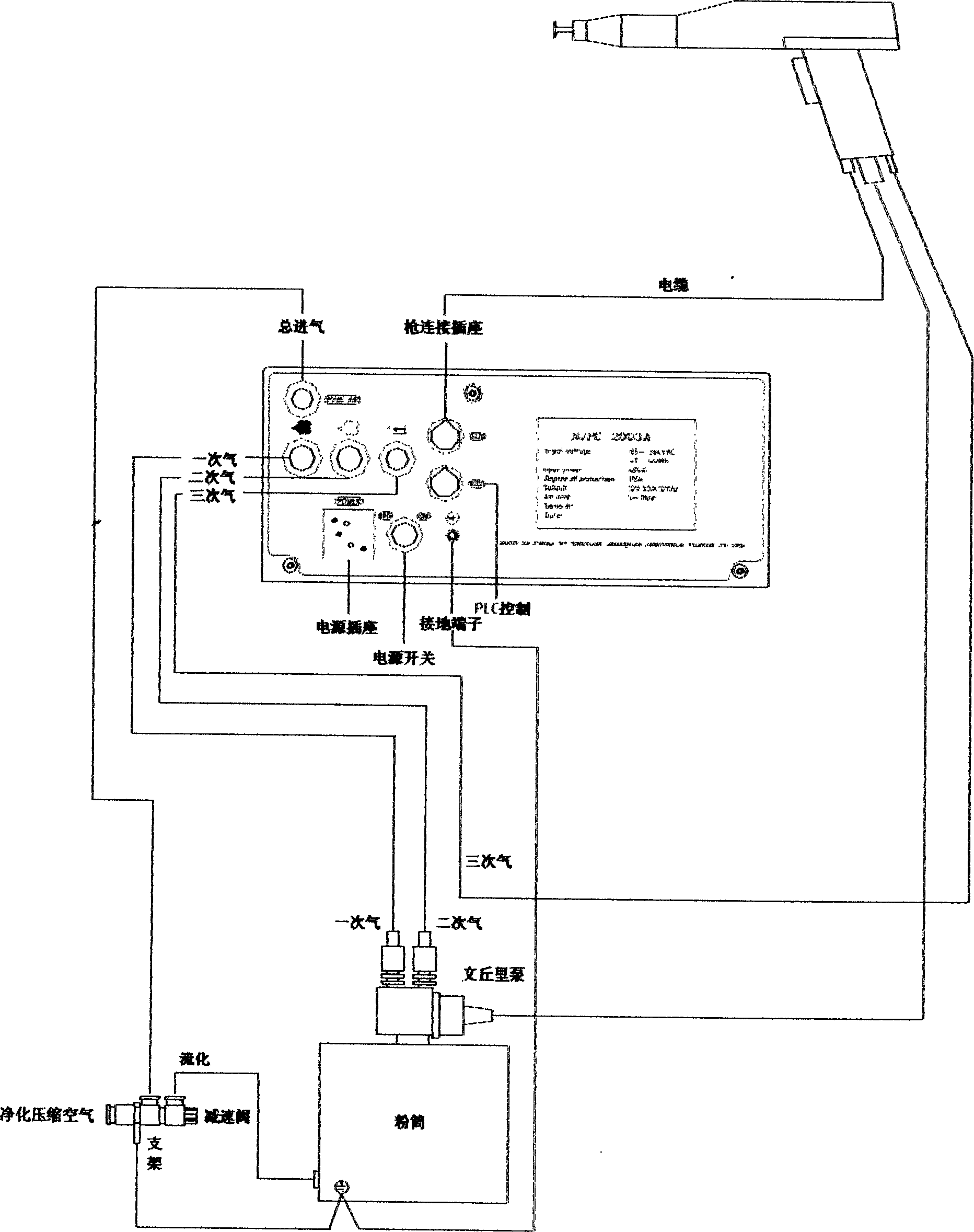

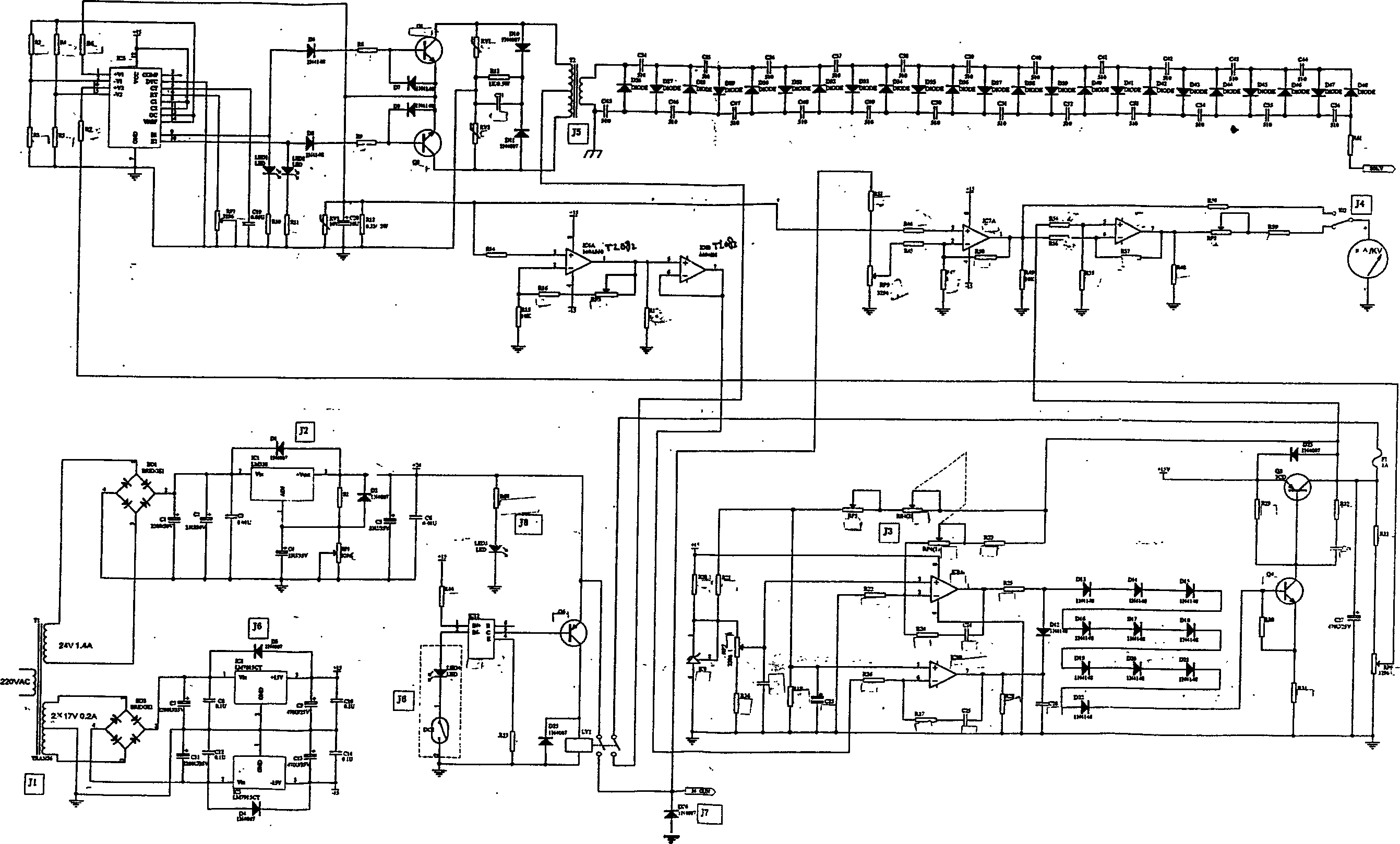

[0008] combine figure 1, figure 2, image 3 , The powder spray film (coating) machine of the present invention is made up of three major parts: high-voltage electrostatic spray gun, controller, powder supply cylinder. 1. High-voltage electrostatic spray gun: Built-in high-voltage generator, the potting material of the transformer U-shaped iron core frame in the high-voltage generator is high-insulation performance, low specific gravity, flexible and transparent 5010A / 5010B epoxy resin material. Its input voltage is 5-12V, current 0.5A, 12KHz square wave; output voltage 40-80KV, negative polarity. 2. Controller: 1. Electrostatic high-voltage control circuit, output voltage 5-12V, current 0.5A, 12KHz square wave, with "distance-current-voltage" automatic control circuit, which can pre-set the maximum spray current of the spray gun to ensure the best powder charge. It is easy to penetrate the "Faraday shielding cage", eliminate the phenomenon of "reverse ionization", comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com