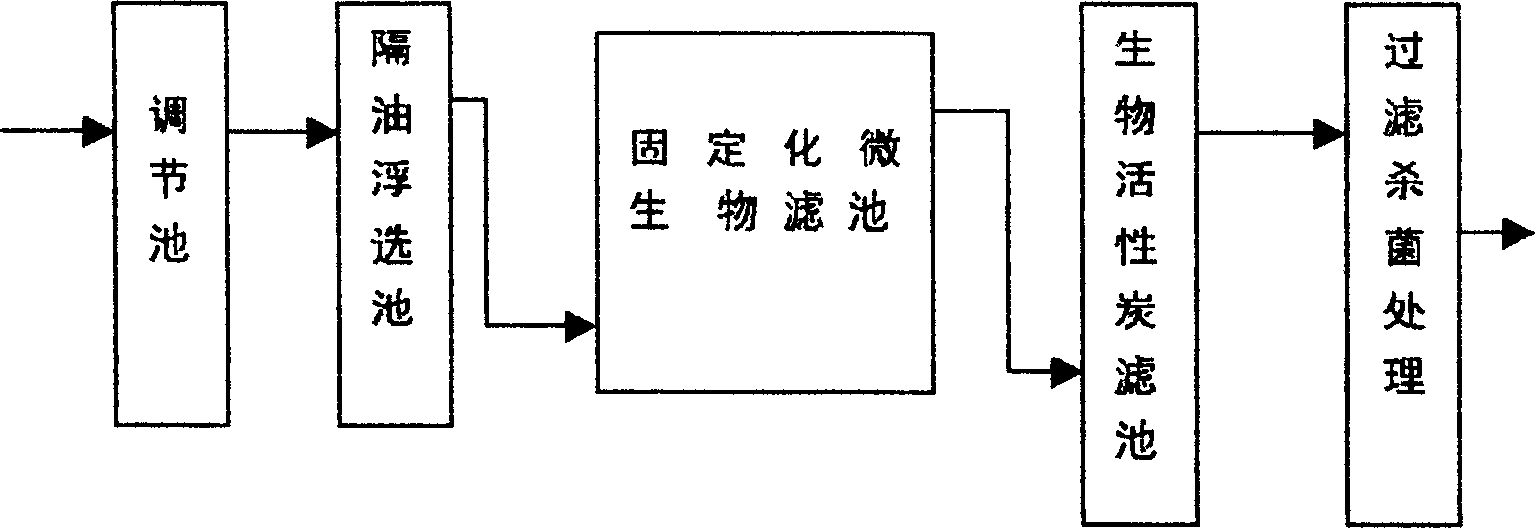

Treatment process for making sewage as recirculating cooling water

A technology of circulating cooling water and treatment process, which is applied in the field of microbial methods, can solve the problems that oil refining and chemical wastewater cannot be reused economically and rationally, and the operating cost is high, and achieve the effects of saving land occupation area, saving infrastructure funds, and high oxygen utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

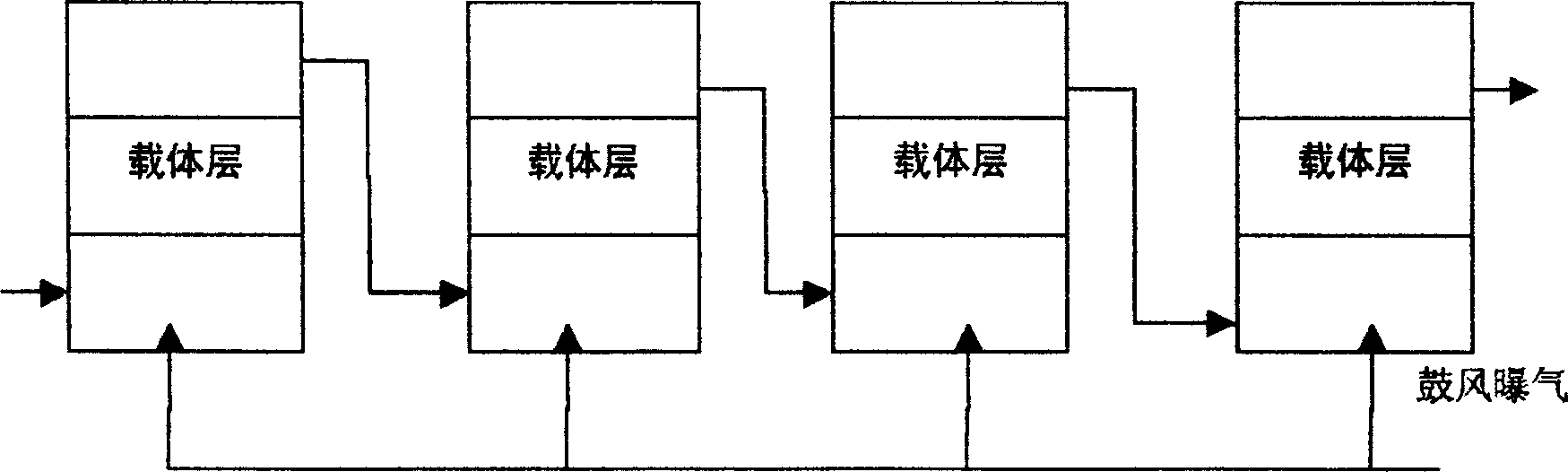

[0039] Example 1: Urban sewage is reused as power cycle cooling water. A certain 30000m 3 / d Sewage reuse project. Influent COD≤150mg / L, BOD≤60mg / L, SS≤60mg / L, NH 4 + -N≤35mg / L; the effluent implements the "Code for Design of Sewage Recycling and Utilization Engineering" (GB50335-2002). The recycled water is used as the supplementary water quality standard of circulating cooling water. square material, it is required to achieve ammonia nitrogen ≤ 1mg / L.

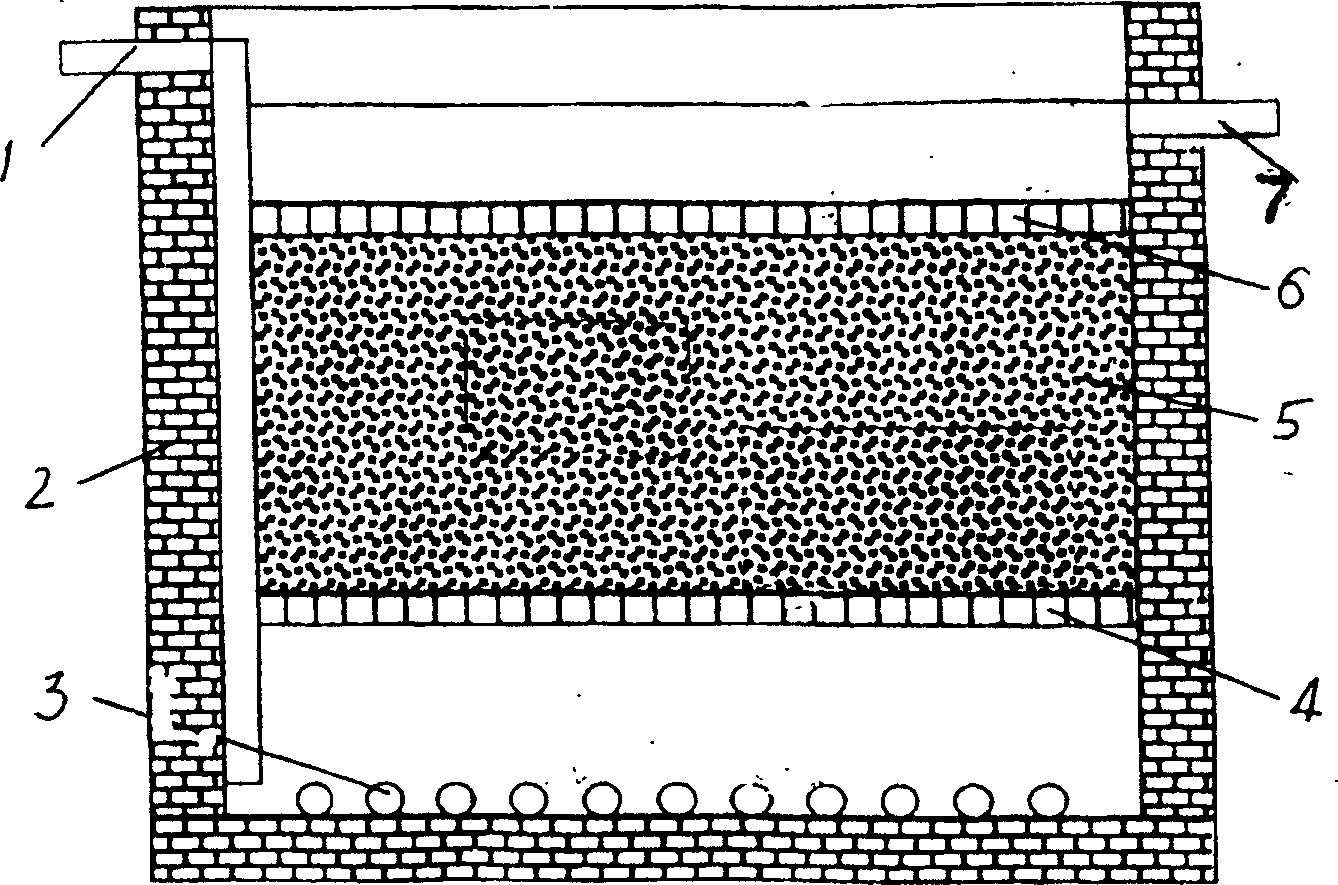

[0040] The biofilter includes immobilized anaerobic biofilter and aerated biofilter, with a total residence time of 4 hours. It is divided into eight groups and five stages in series and parallel operation. The unit pool capacity is 5X5X5.5m. Use carrier 2500m 3 2500Kg of B350 and B500 microorganisms from BL Company of the United States. The residence time of biological activated carbon is 2 hours, and the effluent reaches the required index.

Embodiment 2

[0041] Embodiment 2: For the example of refinery sewage reuse project:

[0042] Sewage treatment project of an oil refinery:

[0043] Water volume: 720m 3 / d

[0044] Biological filter inlet water index: COD: 400-1000mg / L, ammonia nitrogen: 20-200mg / L Outlet water index: The effluent implements the "Sewage Recycling Engineering Design Code" (GB50335-2002) regenerated water is used as circulating cooling water to supplement the water quality standard, and its The water quality standard is: COD≤60mg / L, ammonia nitrogen≤10mg / L.

[0045] The waste water enters the biofilter after oil separation flotation, which is divided into four stages. The first, third and fourth stages are immobilized microbial aerated biological filters, and the second stage is immobilized microbial anaerobic biological filters. The total residence time is 12 hours. , using carrier 160m 3 US BL company B350, B110 microorganisms 160Kg. The biological activated carbon stays for 3 hours, and the effluent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com