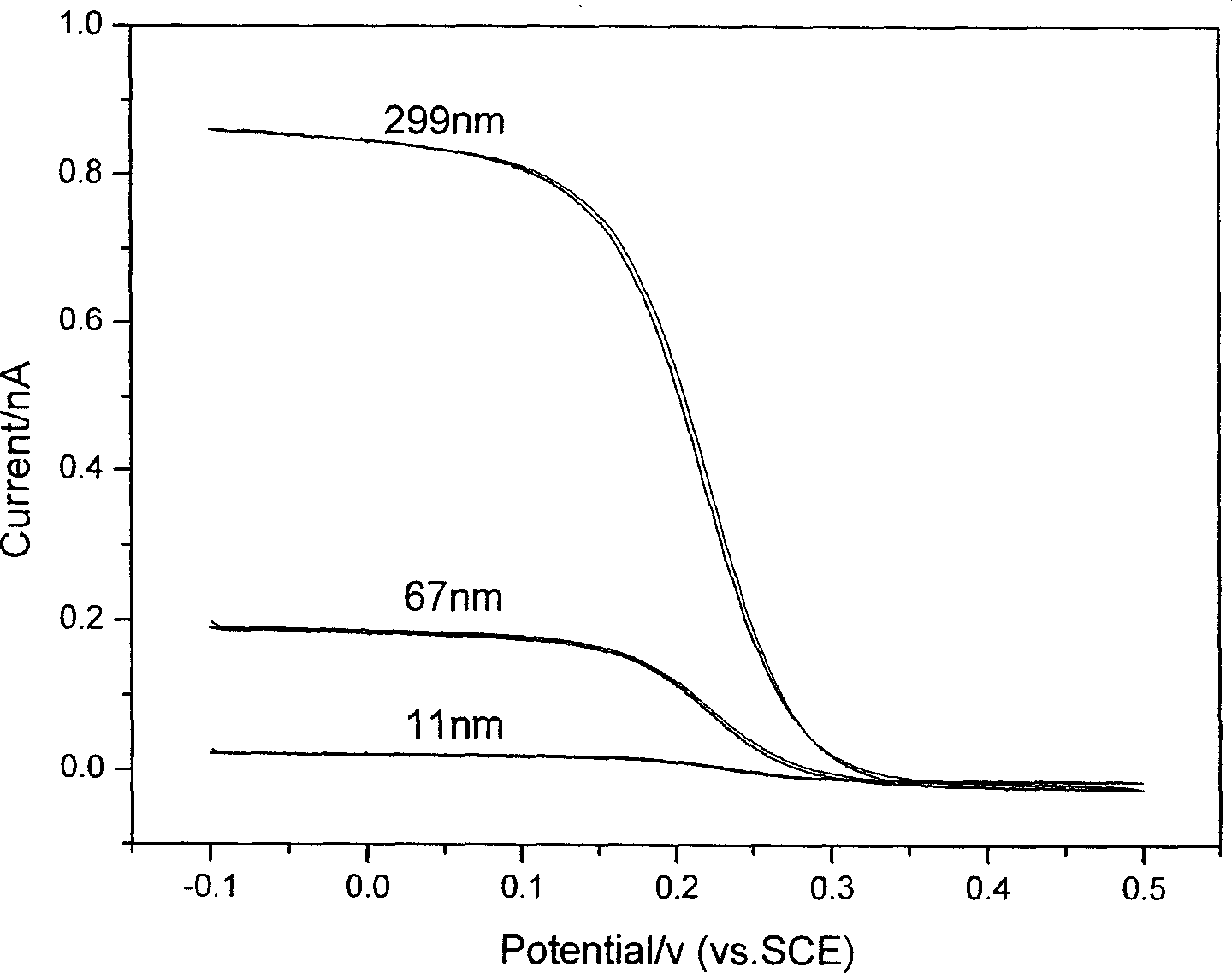

Method for manufacturing nano carbon disk electrode with radius less than 500nm

A disk electrode and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of leaving small pinholes, etc., and achieve improved layer shear strength, stable electrochemical properties, and reproducibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Etching of carbon materials

[0020] The carbon material with a diameter of micron is washed with acetone, ethanol and double distilled water in sequence, and after drying in the air, the electrode and the lead copper wire are bonded with silver conductive glue. After the glue is dry, the carbon material is washed with ethanol and then dried. Then insert one end of the carbon material vertically into a 0.01-1mol / L alkaline solution (such as: 0.1mol / L sodium hydroxide, or 0.1mol / L potassium hydroxide, or 0.1mol / L sodium carbonate). The glassy carbon electrode is used as an auxiliary electrode, and an AC voltage of 0.1-10V is applied until the carbon fiber is etched and broken at the liquid surface, and the etching ends. Remove the carbon fiber, wash with distilled water to remove residual alkali solution, and air dry.

[0021] 2. Insulation on the surface of carbon materials

[0022] Insert the bipolar system composed of etched carbon electrode and platinum sheet el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com